Halogen-free flame-retardant high-temperature-resistant polyphenyl ether alloy material and preparation method thereof

An alloy material and polyphenylene ether technology, which is applied in the field of polymer alloy material processing, can solve the problems of high glass fiber addition fraction, high processing cost, and a large amount of addition, so as to improve the application value, improve the processing performance, and improve the mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

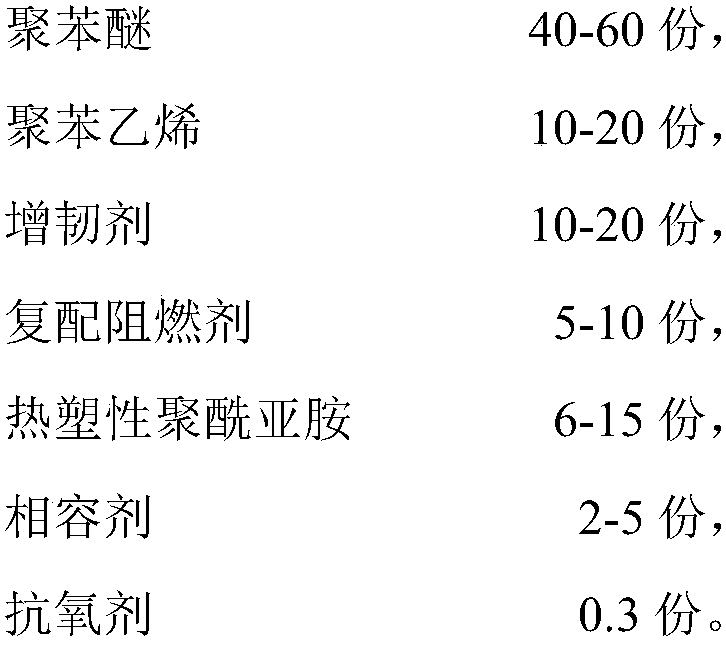

Method used

Image

Examples

Embodiment 1

[0039] Weigh 43 parts of polyphenylene ether (S201A), 15 parts of polystyrene (PG-22), 13 parts of toughening agent SEBS (YH503), 9 parts of compound flame retardant (6 parts of PX200, 3 parts of MCA) by mass parts ), 15 parts of thermoplastic polyimide (TPI450), 3 parts of compatibilizer (PPE-g-MAH), 0.3 part of antioxidant (168), add the raw materials of each component into the high mixing pot and mix evenly, then put The mixed materials are melted and extruded into twin-screws for granulation to obtain a halogen-free flame-retardant high-temperature-resistant polyphenylene ether alloy material; wherein the twin-screw speed is 300r / min, and the screw melting temperature is 280°C.

Embodiment 2

[0041] Weigh 49 parts by mass of polyphenylene ether (S201A), 15 parts of polystyrene (PG-22), 13 parts of toughening agent SEBS (YH503), 9 parts of compound flame retardant (6 parts of PX200, 3 parts of MCA ), 10 parts of thermoplastic polyimide (TPI450), 3 parts of compatibilizer (PPE-g-MAH), 0.3 part of antioxidant (168), add the raw materials of each component into the high mixing pot and mix evenly, then put The mixed materials are melted and extruded into twin-screws for granulation to obtain a halogen-free flame-retardant high-temperature-resistant polyphenylene ether alloy material; wherein the twin-screw speed is 400r / min, and the screw melting temperature is 270°C.

Embodiment 3

[0043]Weigh 52 parts of polyphenylene ether (S201A), 15 parts of polystyrene (PG-22), 13 parts of toughening agent SEBS (YH503), 6 parts of compound flame retardant (4 parts of PX200, 2 parts of MCA ), 10 parts of thermoplastic polyimide (TPI450), 3 parts of compatibilizer (PPE-g-MAH), 0.3 part of antioxidant (168), add the raw materials of each component into the high mixing pot and mix evenly, then put The mixed materials are melted and extruded into twin-screws for granulation to obtain a halogen-free flame-retardant high-temperature-resistant polyphenylene ether alloy material; wherein the twin-screw speed is 400r / min, and the screw melting temperature is 270°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com