Method for measuring content of dimethylbenzene oxidation products by using HPLC external standard method

An oxidation product, xylene technology, applied in the field of analysis, can solve the problems of difficult separation, reduced analysis accuracy, interference of qualitative and quantitative analysis of ortho, meta, and terephthalic acid, and achieves the effect of simple and easy method and short analysis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

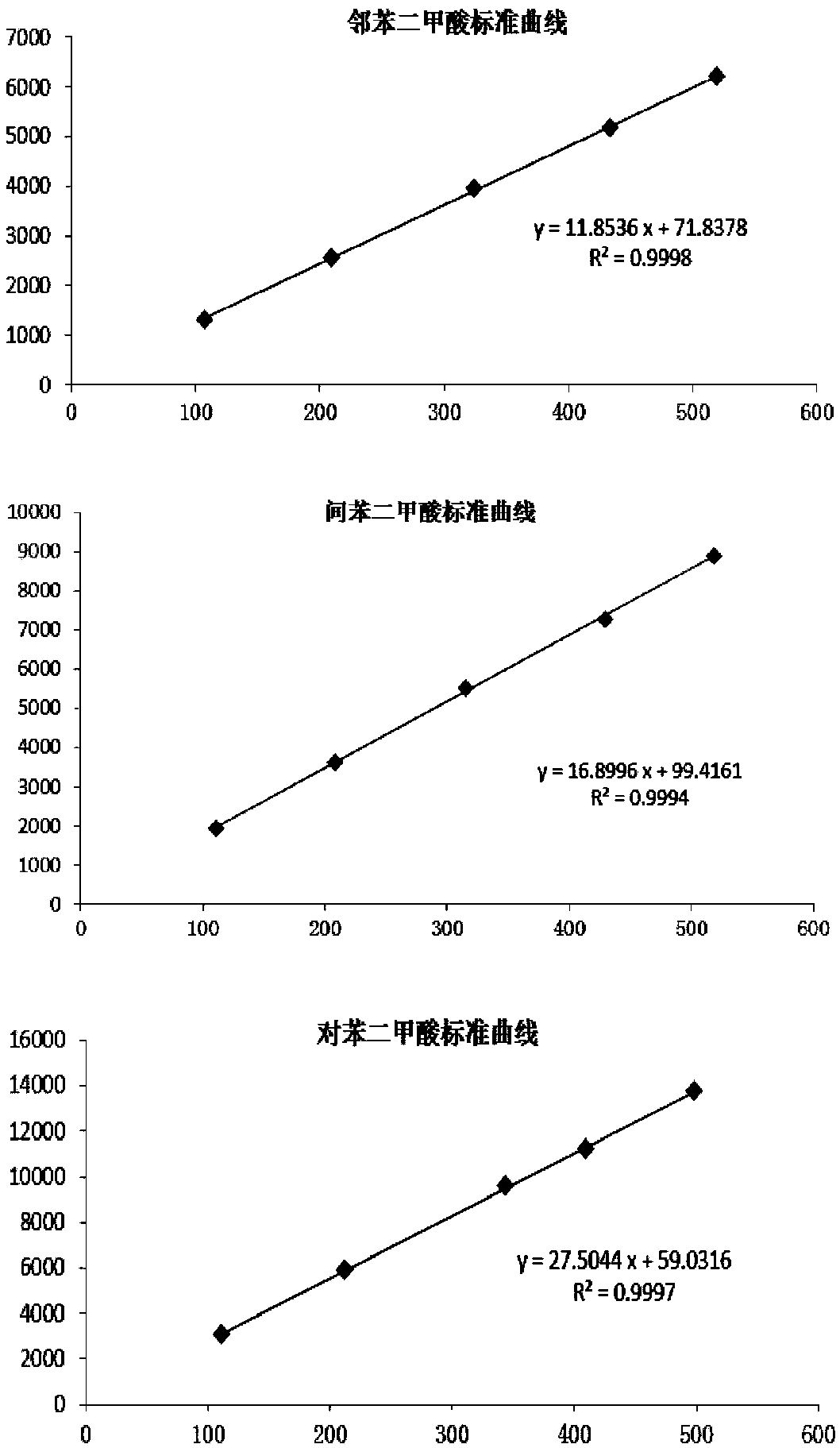

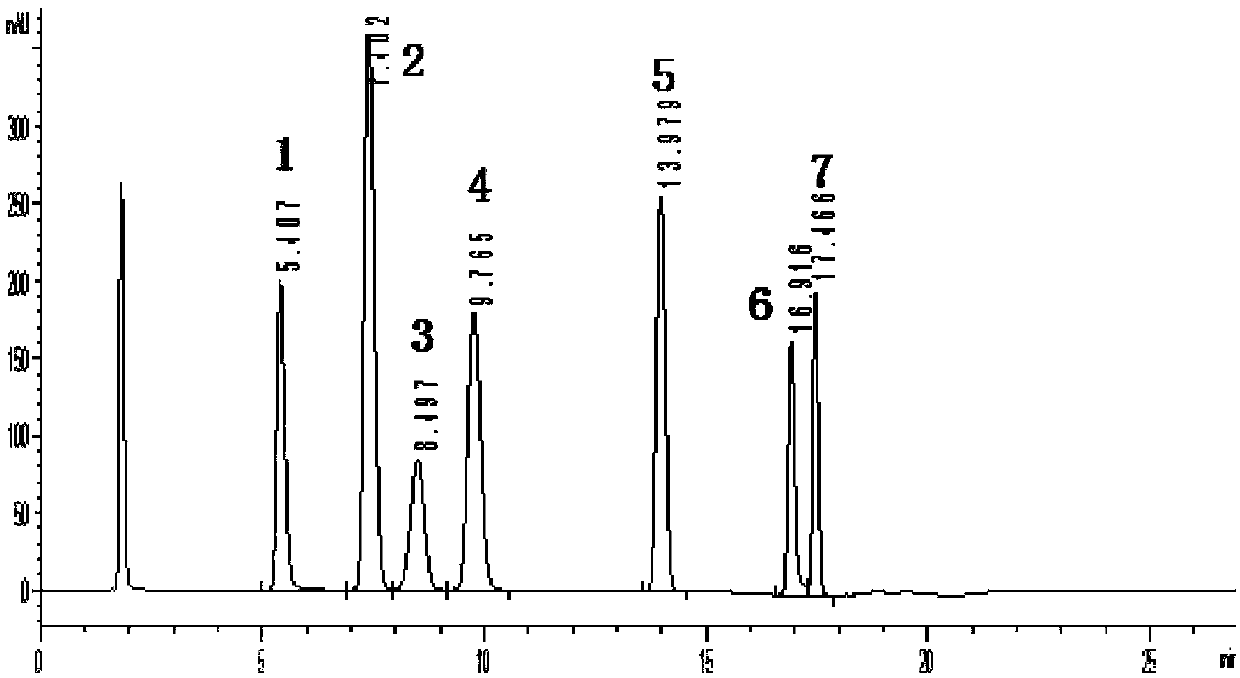

[0045] There is a batch of samples of xylene oxidation products with unknown concentration, the ratio of o-, m-, and terephthalic acid is about 1:1:1, the content of the three needs to be determined, and the detection is carried out by high-performance liquid chromatography and external standard method Quantitative analysis, the specific steps include:

[0046] (1) Preparation of standard solution: Accurately weigh 10.0mg, 20.0mg, 30.0mg, 40.0mg, 50.0mg of each standard sample of phthalic acid, isophthalic acid, and terephthalic acid into 5 beakers, and add 10mL dimethyl sulfoxide to dissolve the sample, transfer it completely to a 100mL volumetric flask, add methanol to dissolve and mix, and set the volume to the mark to obtain mixed standard solutions I, II, III, IV, V, and its phthalic acid , isophthalic acid, and terephthalic acid are 100.0mg / L, 200.0mg / L, 300.0mg / L, 400.0mg / L, and 500.0mg / L respectively;

[0047] (2) Preparation of sample solution: Accurately weigh three...

Embodiment 2

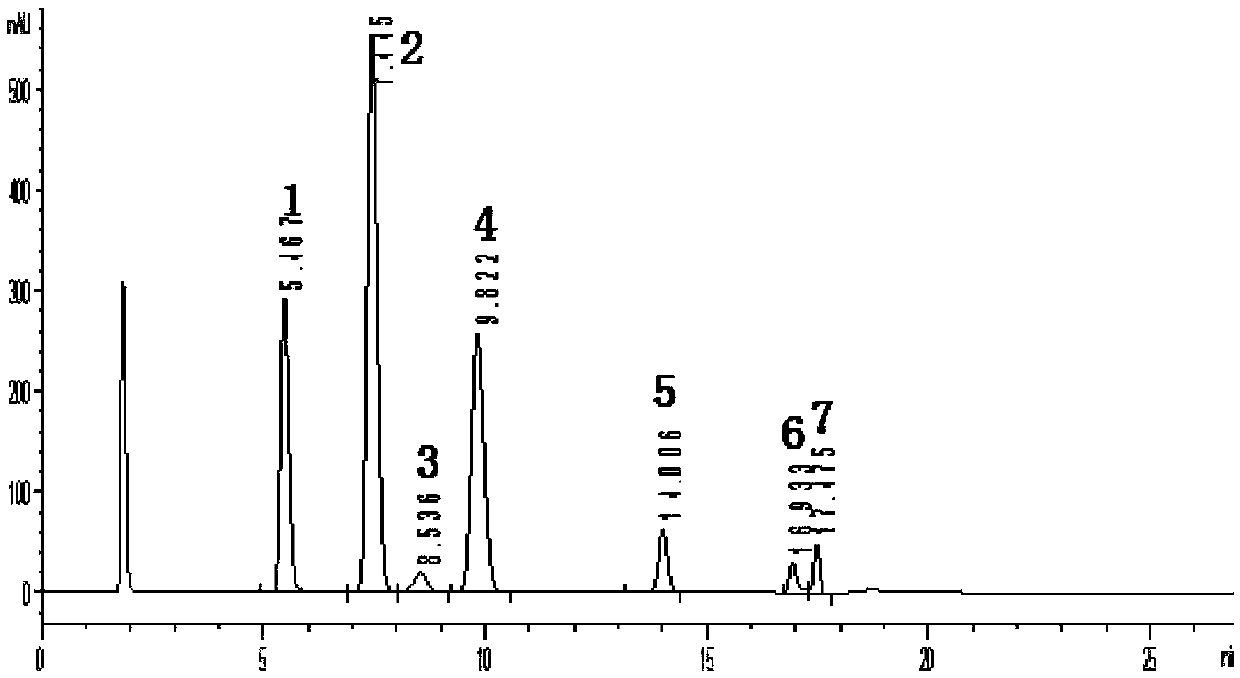

[0054] There are a batch of samples of xylene oxidation products with unknown concentrations. The ratio of o-, m-, and terephthalic acid is about 1:1:2. It is necessary to measure the content of the three, and use high-performance liquid chromatography for detection and external standard method Quantitative analysis, the specific steps include:

[0055] (1) Preparation of standard solution: Accurately weigh 10.0mg, 20.0mg, 30.0mg, 40.0mg, 50.0mg of each standard sample of phthalic acid, isophthalic acid, and terephthalic acid into 5 beakers, and add 10mL dimethyl sulfoxide (DMSO), to dissolve the sample, transfer it completely to a 100mL volumetric flask, add methanol to dissolve and mix, and set the volume to the mark to obtain mixed standard solutions I, II, III, IV, V, and its adjacent The concentrations of phthalic acid, isophthalic acid and terephthalic acid are 100.0mg / L, 200.0mg / L, 300.0mg / L, 400.0mg / L, 500.0mg / L respectively;

[0056] (2) Preparation of sample solutio...

Embodiment 3

[0061] There are a batch of samples of xylene oxidation products with unknown concentrations. The ratio of o-, m-, and terephthalic acid is about 1:2:1. It is necessary to measure the content of the three, and use high-performance liquid chromatography for detection and external standard method Quantitative analysis, the specific steps include:

[0062] (1) Preparation of standard solution: Accurately weigh 10.0mg, 20.0mg, 30.0mg, 40.0mg, 50.0mg of each standard sample of phthalic acid, isophthalic acid, and terephthalic acid into 5 beakers, and add 10mL dimethyl sulfoxide to dissolve the sample, transfer it completely to a 100mL volumetric flask, add methanol to dissolve and mix, and set the volume to the mark to obtain mixed standard solutions I, II, III, IV, V, and its phthalic acid , isophthalic acid, and terephthalic acid are 100.0mg / L, 200.0mg / L, 300.0mg / L, 400.0mg / L, and 500.0mg / L respectively;

[0063] (2) Preparation of sample solution: Accurately weigh three parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com