A kind of lithium ion capacitor and preparation method thereof

A technology of capacitors and lithium ions, which is applied in the field of new energy storage, can solve problems such as difficult precise control requirements, high prices, and unsafety, and achieve the effects of improving safety and reliability, reducing production costs, and shortening cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

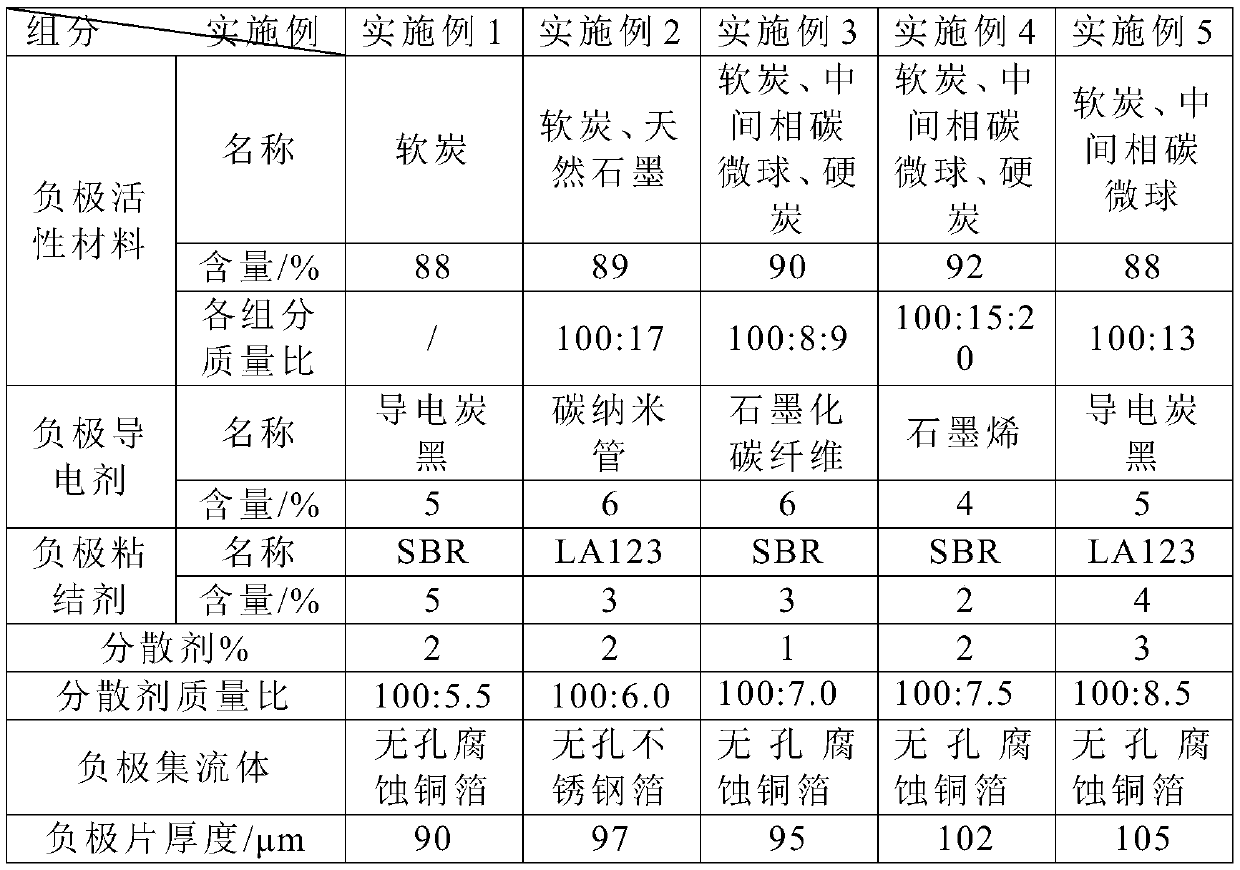

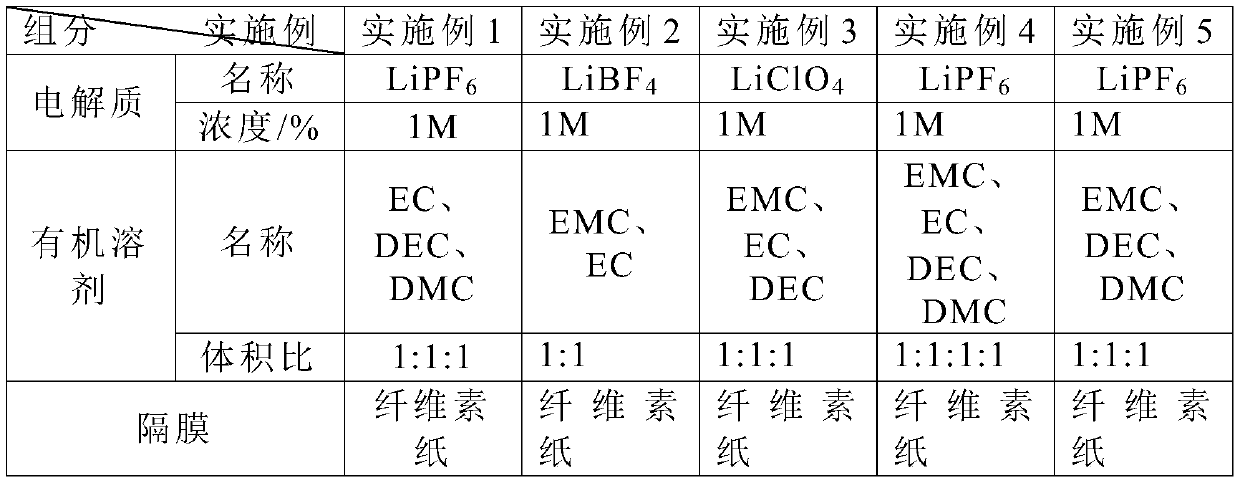

Embodiment 1~5

[0042] The lithium ion capacitor in Examples 1 to 5 includes a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte. The positive electrode sheet, the negative electrode sheet and the separator are immersed in the electrolyte,

[0043] The thickness of the positive electrode sheet is 200-240μm. The positive electrode sheet includes a positive electrode current collector and a positive electrode material coated on the positive electrode current collector. The positive electrode current collector is non-porous corroded aluminum foil or non-porous stainless steel foil. The positive electrode material includes the following mass percentage components:

[0044] Activated carbon: 30~60%,

[0045] LiFePO 4 +NCM: 15~50%,

[0046] Li 6 CoO 4 : 5~20%,

[0047] Positive electrode conductive agent: 3-8%,

[0048] Positive electrode binder: 5-12%,

[0049] LiFePO 4 And LiNi 0.5 Co 0.3 Mn 0.2 O 2 The mass ratio is 1:4~3:2.

[0050] The thickness of the negative electrode ...

Embodiment 6~10

[0068] The preparation method of the lithium ion capacitor in Examples 6-10 includes the following steps:

[0069] (1) Prepare raw materials: prepare raw materials according to the components and contents in Example 1;

[0070] (2) Preparation of positive electrode sheet: combining activated carbon, LiFePO 4 , NCM, Li 6 CoO 4 , The positive electrode conductive agent and the positive electrode binder are dissolved in NMP in sequence, and the high-speed stirring equipment is used to stir for 4-6h at -0.03~-0.1MPa vacuum pressure and 8000~10000r / min stirring speed for vacuum high-speed dispersion treatment to form a uniform positive electrode In the process of the slurry, the vacuum high-speed dispersion treatment is carried out at the same time with a power of 500w ultrasonic treatment, the positive electrode slurry is coated on the positive and negative sides of the positive current collector, and the coating is dried stepwise. The drying system is different from multiple sections. ...

Embodiment 11~14

[0077] The raw materials were prepared according to the components and contents of Examples 2 to 5 respectively, and the lithium ion capacitor was prepared according to the preparation method in Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com