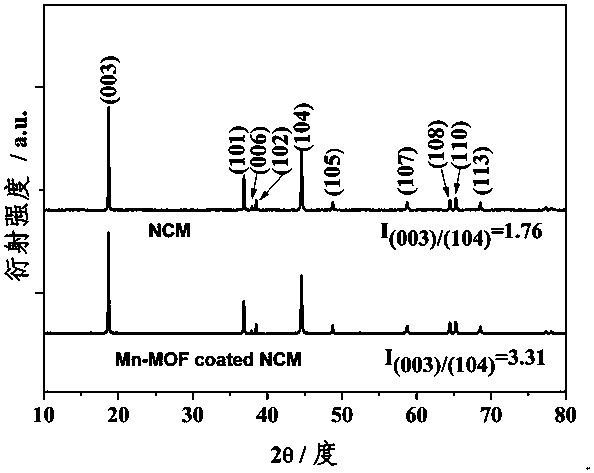

Manganese-based metal organic framework compound-coated lithium ion battery ternary positive electrode material and preparation method thereof

A lithium-ion battery, organic framework technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as poor cycle stability, and achieve improved electrochemical performance, improved cycle stability, and improved high-rate cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A method for preparing a lithium-ion battery ternary cathode material coated with a manganese-based metal-organic framework compound. The obtained material is abbreviated as Mn-MOF coated NCM:

[0036] Step 1) Precursor preparation, accurately weigh 2.6821 g of nickel sulfate, 2.8394 g of cobalt sulfate, and 1.7073 g of manganese sulfate in 200 mL of deionized water and mix to form a solution. At the same time, weigh 3.1930 g of sodium carbonate and dissolve in 200 mL solution in deionized water, in N 2 Under a protective atmosphere, the above two solutions were continuously pumped into the reactor (five-necked flask) through a peristaltic pump. At the same time, ammonia solution was added dropwise to adjust the pH to 8.5. The reaction was carried out at rpm / min. After the reaction was completed, it was aged for 12 h, and the product was filtered, washed with deionized water several times, and then dried in vacuum at 80°C for 12 h to obtain the precursor;

[0037] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com