Compound dura mater (spinal dura mater) implant as well as preparation method and application thereof

A composite implant technology, applied in the field of biomedicine, can solve the problems of immune rejection, infection, low mechanical properties, etc., and achieve the effects of preventing spillover, promoting regeneration, and promoting combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

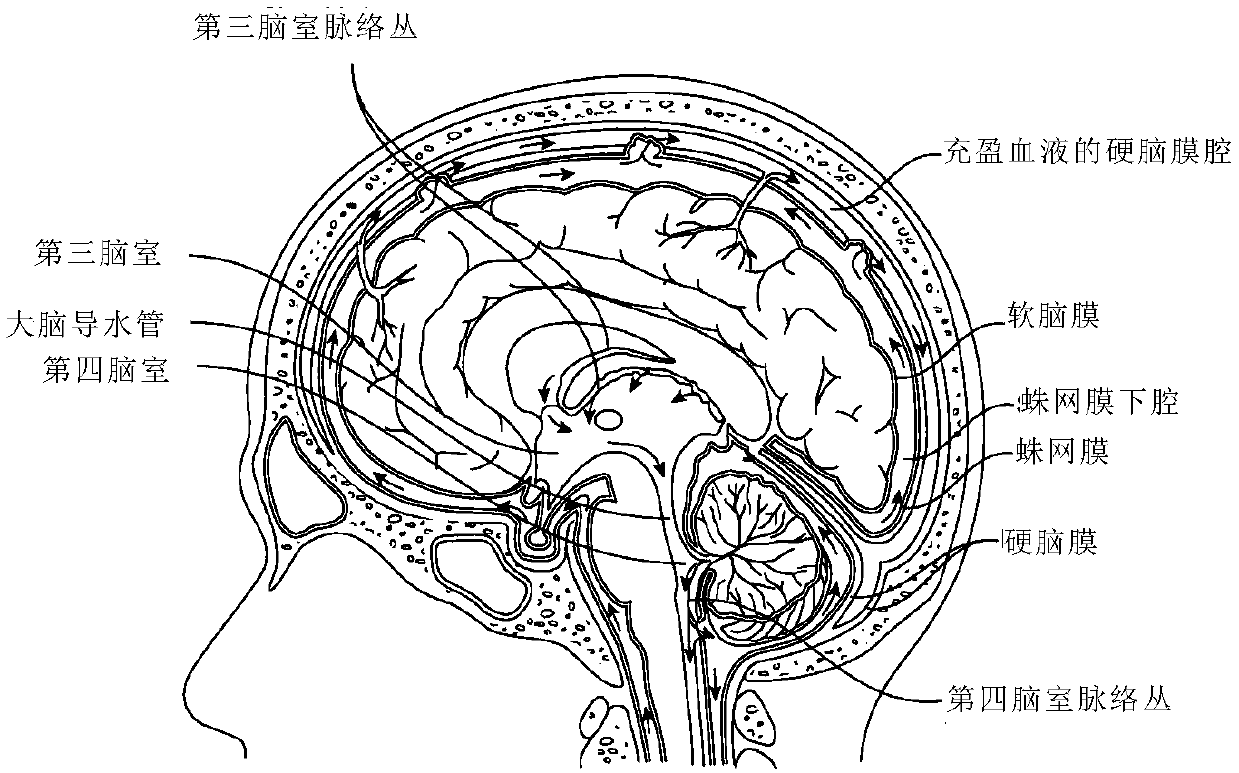

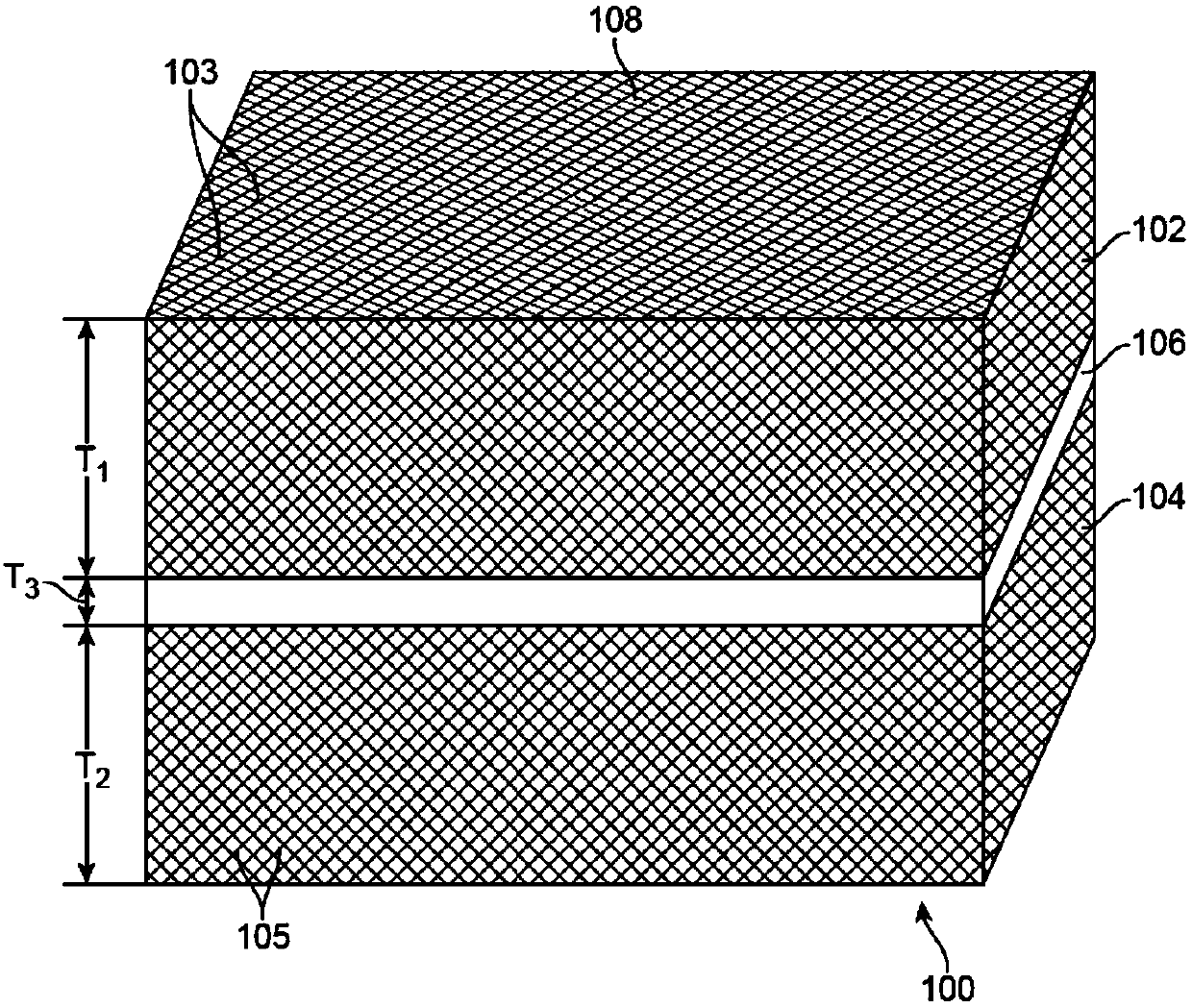

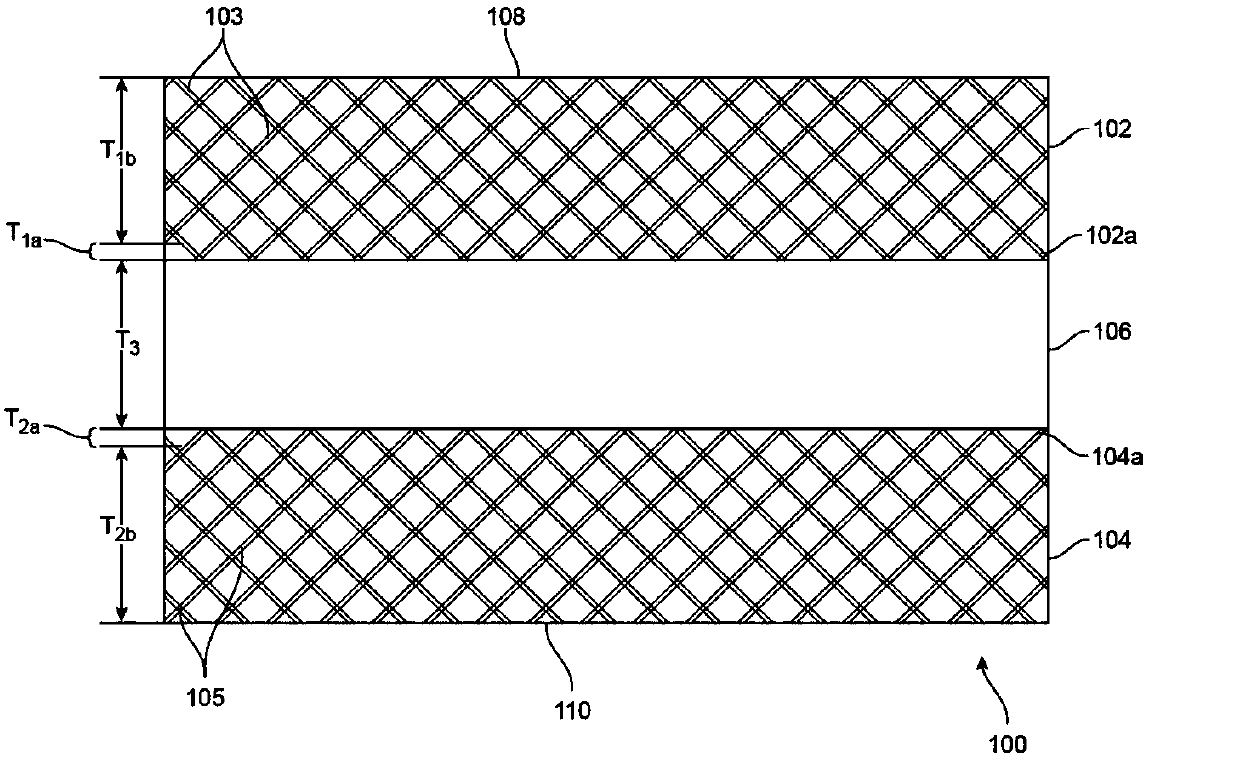

[0093] The preparation method of the composite dura (spinal) membrane implant has multiple embodiments, including tightly combining the first porous polymer layer with one side of the third polymer layer, and combining the second porous polymer layer with the first The other side of the three polymer layers is tightly bonded. The first porous polymer layer is on top of the implant and the second porous polymer layer is on the bottom of the implant.

[0094] The third polymer layer may be non-porous or its porosity sufficiently low to prevent cerebrospinal fluid spillage. The preparation method further includes impregnating the first porous polymer layer with an osteoconductive material, and impregnating the second porous polymer layer with a collagen material.

[0095] In some embodiments, heat pressing can be used in combination. For example, combining the first porous polymer layer with the third polymer layer includes heating the first porous polymer layer or the third po...

Embodiment 1

[0107] A composite dura (spine) membrane implant composed of three layers of polyetherketoneketone material: the surface of the polyetherketoneketone fabric of the first porous layer has a bone-like apatite coating with a porosity of 50% , thickness 2mm; the porosity of the polyether ketone ketone fabric in the middle layer is 0, and the thickness is 0.5 mm; the surface of the polyether ketone ketone fabric in the second porous layer has type I collagen coating, the porosity is 50%, and the thickness is 1 mm.

Embodiment 2

[0109] A composite dura (spine) membrane implant composed of three layers of ultra-high molecular weight polyethylene material: the first porous layer is DSM's The surface of the fabric is a bone-like apatite coating with a porosity of 60% and a thickness of 2mm; the middle layer is an ultra-high molecular weight polyethylene material with a porosity of 0.1% and a thickness of 0.5mm; the second porous layer is Fabric, the surface of which is coated with type I collagen, with a porosity of 60% and a thickness of 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com