Ultrasonic treatment system for sewage reuse and water treatment method of ultrasonic treatment system

A treatment system, ultrasonic technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc. The effect of loss, reducing pulp spoilage and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 takes papermaking mid-stage water as an example

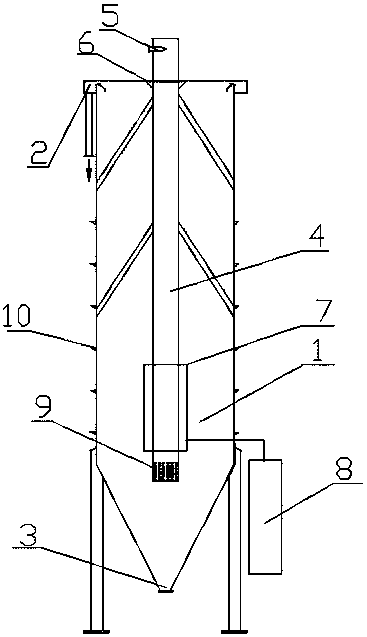

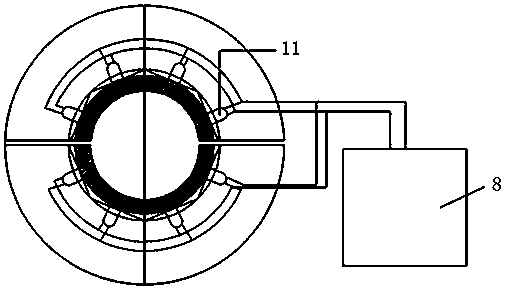

[0028] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an n-level ultrasonic treatment device for reclaimed water reuse; the ultrasonic treatment device for water reuse in the middle section of papermaking includes a housing 1, an overflow port 2 is provided on the top of the housing 1, and a sewage outlet is provided at the bottom of the housing 1 3. A water filter pipe 4 is fixed inside the housing 1 through a stainless steel pipe; A supporting flange 6 is provided, and the supporting flange 6 is arranged on the top inside of the housing 1; the bottom end of the filter pipe 4 is provided with an ultrasonic transducer 7, and the ultrasonic transducer 7 includes an ultrasonic vibrator 11, and the ultrasonic vibrator 11 passes through a wire Connect with ultrasonic generator 8. The housing 1 includes a cylindrical barrel portion and a conical sediment...

Embodiment 2

[0030] Example 2 Domestic sewage treatment as an example

[0031] The water treatment method of the domestic sewage ultrasonic treatment system comprises the following steps:

[0032] (1) Primary treatment of domestic sewage: Store domestic sewage in the water collection well, and lift the domestic sewage to the first-level ultrasonic treatment device through the water pump. The ultrasonic transducer generates a strong magnetic field through the ultrasonic transducer, and the frequency of the ultrasonic vibrator is 33KHz. , sound energy density 0.08 W / cm 3 . The magnetic field reaches 5000 gauss. The domestic sewage is magnetized by a strong magnetic field to generate eddy current reaction, and the first homogeneous water distribution is completed. The solid matter quickly sinks to the bottom of the shell, and the clear water floats to overflow; The slurry tank is directly connected to the Internet to realize continuous filling;

[0033] (2) Clear water reprocessing: The cl...

Embodiment 3

[0036] Embodiment 3 Take the water in the middle section of mine coal washing as an example

[0037] This embodiment includes an n-level ultrasonic treatment device for reclaimed water reuse; the ultrasonic treatment device for water reuse in the middle section of mine coal washing and mine washing includes a housing 1, an overflow port 2 is provided at the top of the housing 1, and an overflow port 2 is provided at the bottom of the housing 1. There is a sewage outlet 3, and the inside of the housing 1 is fixed with a water filter pipe 4 through a stainless steel pipe; the upper end of the water filter pipe 4 protrudes from the top of the housing 1, and the upper end of the water filter pipe 4 is provided with a water inlet pipe 5; the water filter pipe 4 and the housing 1. The connection part is provided with a support flange 6, which is provided at the top inside the shell 1; the bottom end of the water filter pipe 4 is provided with an ultrasonic transducer 7, and the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com