PODE (polyoxymethylene dimethyl ethers) catalyst

A technology of dimethyl ether and catalyst, applied in the field of polyoxymethylene dimethyl ether catalyst, can solve the problem of low product selectivity and achieve good yield and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

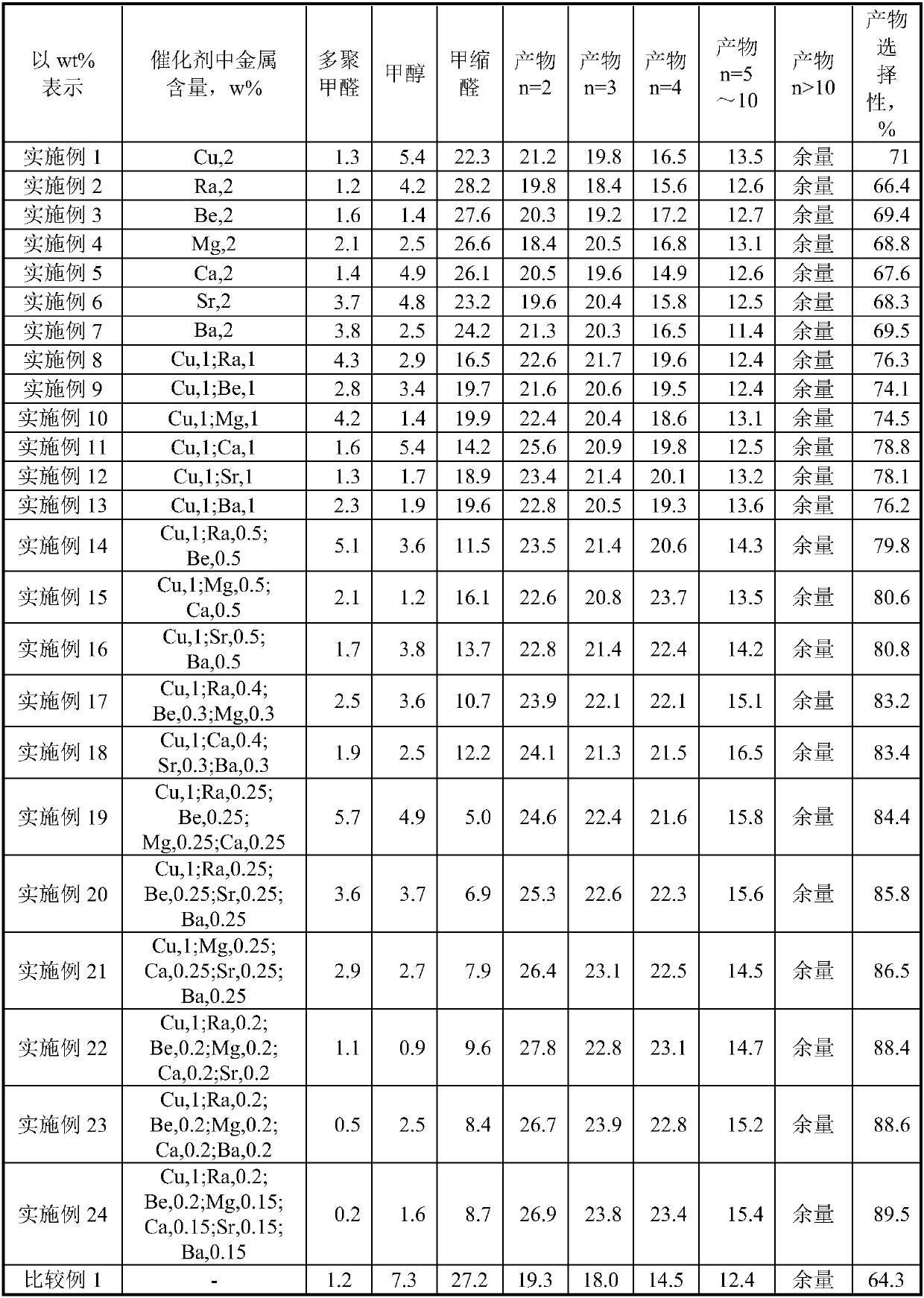

Examples

Embodiment 1

[0038] 1. Preparation of catalyst

[0039] After washing the sodium sulfonate polystyrene cation exchange resin 7320 with deionized water until the water flows out, soak it in 4w% hydrochloric acid four times, each use is equivalent to 10 times the dry weight of the sodium sulfonate polystyrene cation exchange resin 7320 Soaked in 4w% hydrochloric acid for 4 hours each time, and then washed with deionized water until the eluate is free of chloride ions. After drying at 60°C, a sulfonic acid type polystyrene cation exchange resin is obtained, with a total exchange capacity of 4.10 mmol / g. Take the sulfonic acid type polystyrene cation exchange resin equivalent to 98 grams of dry base resin and 300 ml of Cu(OH) containing 2 grams of Cu 2 The aqueous suspension is mixed, 1 drop of glacial acetic acid is added, mixed, and allowed to stand at room temperature for 24 hours, and dried in a vacuum drying oven to a constant weight to obtain a catalyst with a Cu content of 2w%.

[0040] 2. ...

Embodiment 2

[0043] 1. Preparation of catalyst

[0044] After washing the sodium sulfonate polystyrene cation exchange resin 7320 with deionized water until the water flows out, soak it in 4w% hydrochloric acid four times, each use is equivalent to 10 times the dry weight of the sodium sulfonate polystyrene cation exchange resin 7320 Soaked in 4w% hydrochloric acid for 4 hours each time, and then washed with deionized water until the eluate is free of chloride ions. After drying at 60°C, a sulfonic acid type polystyrene cation exchange resin is obtained, with a total exchange capacity of 4.10 mmol / g. Take the sulfonic acid type polystyrene cation exchange resin equivalent to 98 grams of dry base resin, and add 300ml of Ra(OH) containing 2 grams of Ra under nitrogen protection 2 The aqueous suspension was mixed, 1 drop of glacial acetic acid was added, mixed, and allowed to stand at room temperature for 24 hours, and dried in a vacuum drying oven to a constant weight to obtain a catalyst with ...

Embodiment 3

[0048] 1. Preparation of catalyst

[0049] After washing the sodium sulfonate polystyrene cation exchange resin 7320 with deionized water until the water flows out, soak it in 4w% hydrochloric acid four times, each use is equivalent to 10 times the dry weight of the sodium sulfonate polystyrene cation exchange resin 7320 Soaked in 4w% hydrochloric acid for 4 hours each time, and then washed with deionized water until the eluate is free of chloride ions. After drying at 60°C, a sulfonic acid type polystyrene cation exchange resin is obtained, with a total exchange capacity of 4.10 mmol / g. Take the sulfonic acid type polystyrene cation exchange resin equivalent to 98 grams of dry base resin, and add 300ml of Be(OH) containing 2 grams of Be under nitrogen protection 2 The aqueous suspension is mixed, 1 drop of glacial acetic acid is added, mixed, allowed to stand at room temperature for 24 hours, and dried to constant weight in a vacuum drying oven to obtain a catalyst with a Be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com