Heat insulation material containing rosin ester polyol and preparation method thereof

A technology of thermal insulation material and polyol, applied in the field of polyurethane thermal insulation materials, can solve the problems of vacuum nozzle foam cracking, foam and shell falling off, low heat resistance and other problems, and achieve the effects of small compression deformation, simple production and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

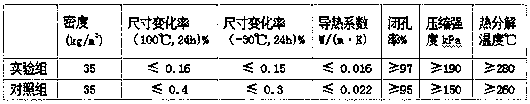

Examples

Embodiment 1

[0019] A thermal insulation material containing rosin ester polyol and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0020] 80 parts of rosin ester polyol, 100 parts of polymethylene polyphenyl polyisocyanate, 35 parts of expanded vermiculite, 6 parts of jute fiber, 12 parts of HFC-245fa, 3 parts of water-soluble silicone oil, and 3 parts of quaternary ammonium salt.

[0021] The length of the jute fiber is between 3mm and 20mm, and the diameter of the expanded vermiculite is between 10nm and 100nm.

[0022] The preparation method of the thermal insulation material is to weigh the raw materials according to the parts by mass, mix them, stir them evenly at a high speed, pour them into a mold, and mature them for 48 hours.

Embodiment 2

[0024] A thermal insulation material containing rosin ester polyol and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0025] 70 parts of rosin ester polyol, 70 parts of polymethylene polyphenyl polyisocyanate, 20 parts of expanded vermiculite, 5 parts of jute fiber, 8 parts of HFC-245fa, 2 parts of water-soluble silicone oil, and 2 parts of quaternary ammonium salt.

[0026] The length of the jute fiber is between 3mm and 20mm, and the diameter of the expanded vermiculite is between 10nm and 100nm.

[0027] The preparation method of the thermal insulation material is to weigh the raw materials according to the parts by mass, mix them, stir them evenly at a high speed, pour them into a mold, and mature them for 48 hours.

Embodiment 3

[0029] A thermal insulation material containing rosin ester polyol and a preparation method thereof, the material is made of the following raw materials in parts by weight:

[0030] 90 parts of rosin ester polyol, 135 parts of polymethylene polyphenyl polyisocyanate, 50 parts of expanded vermiculite, 8 parts of jute fiber, 15 parts of HFC-245fa, 5 parts of water-soluble silicone oil, and 5 parts of quaternary ammonium salt.

[0031] The length of the jute fiber is between 3mm and 20mm, and the diameter of the expanded vermiculite is between 10nm and 100nm.

[0032] The preparation method of the thermal insulation material is to weigh the raw materials according to the parts by mass, mix them, stir them evenly at a high speed, pour them into a mold, and mature them for 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com