Chloro acetaldoxime cleaner production and RuO2@TNTs anode used for cleaner production

An anode and anodic oxidation technology, applied in the direction of electrodes, liquid chemical plating, coating, etc., can solve the problems of long cycle, limited practical application, complicated experimental operation, etc., and achieve strong adhesion, uniform distribution of components, and technological conditions simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

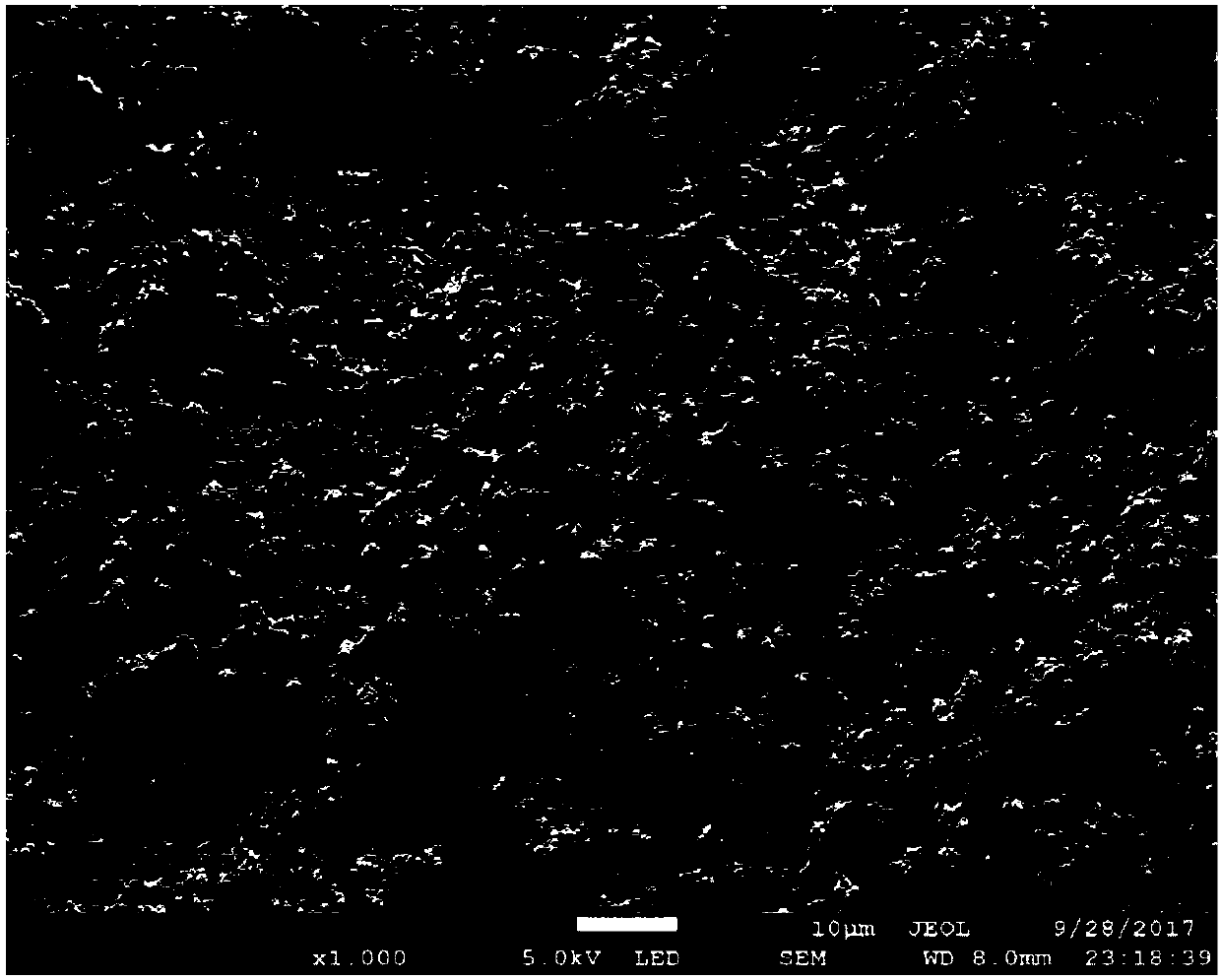

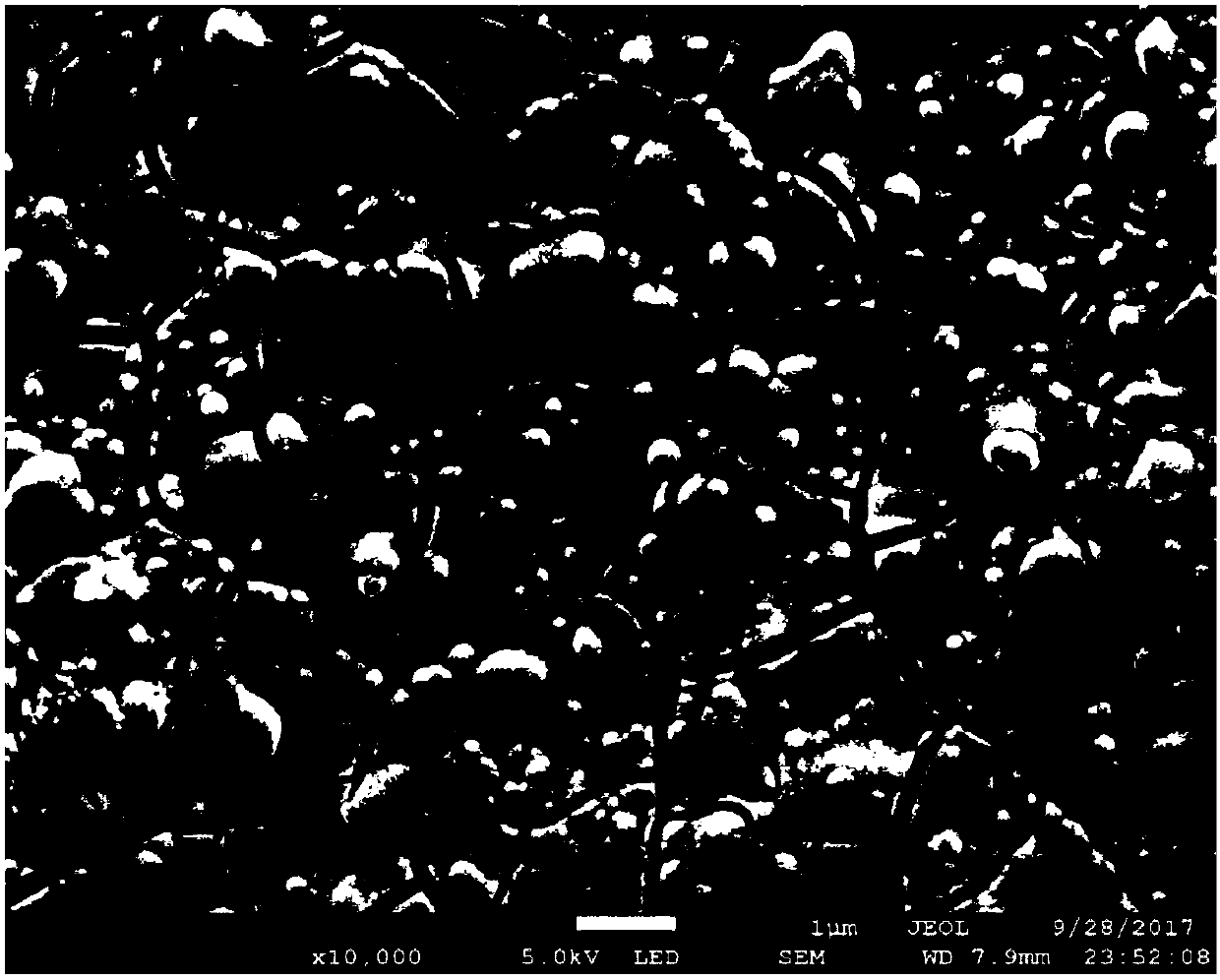

[0043] The titanium mesh was cut into a size of 80.0mm×10.0mm×0.2mm, mechanically polished, acetone and ethanol sonochemically degreased for 30 minutes each. At room temperature, chemical polishing treatment (polishing liquid: HF: HNO 3 :H 2 O=1:4:5 volume ratio), and then rinsed with deionized water for use. Accurately weigh 1.576g of H 2 C 2 o 4 ·H 2O and 0.75g of ammonium fluoride are completely dissolved with a certain amount of distilled water, and the volume is adjusted to 100mL with distilled water to prepare 0.125M H 2 C 2 o 4 ·H 2 O, mass fraction is the ammonium fluoride solution of 0.75%. Ultrasonic stirring to fully dissolve. The cut electrode was immersed in the prepared solution as the anode, and the platinum mesh was used as the cathode, the temperature was kept at 25°C, the voltage was 30V, and the nanostructured TNTs anode was obtained after continuous anodic oxidation for 1.5 hours. Use adhesive tape to adhere and tear off the nano-TNTs structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com