Preparation method of complete pellet sheep feed

A pellet feed and full-price technology, which is applied in the field of preparation of full-price sheep pellet feed, can solve the problems of low fiber content, unsuitable for herbivore digestion, and inability to satisfy herbivore to absorb comprehensive nutrition, so as to increase fungus and promote sheep rumen Fermentation, the effect of improving feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

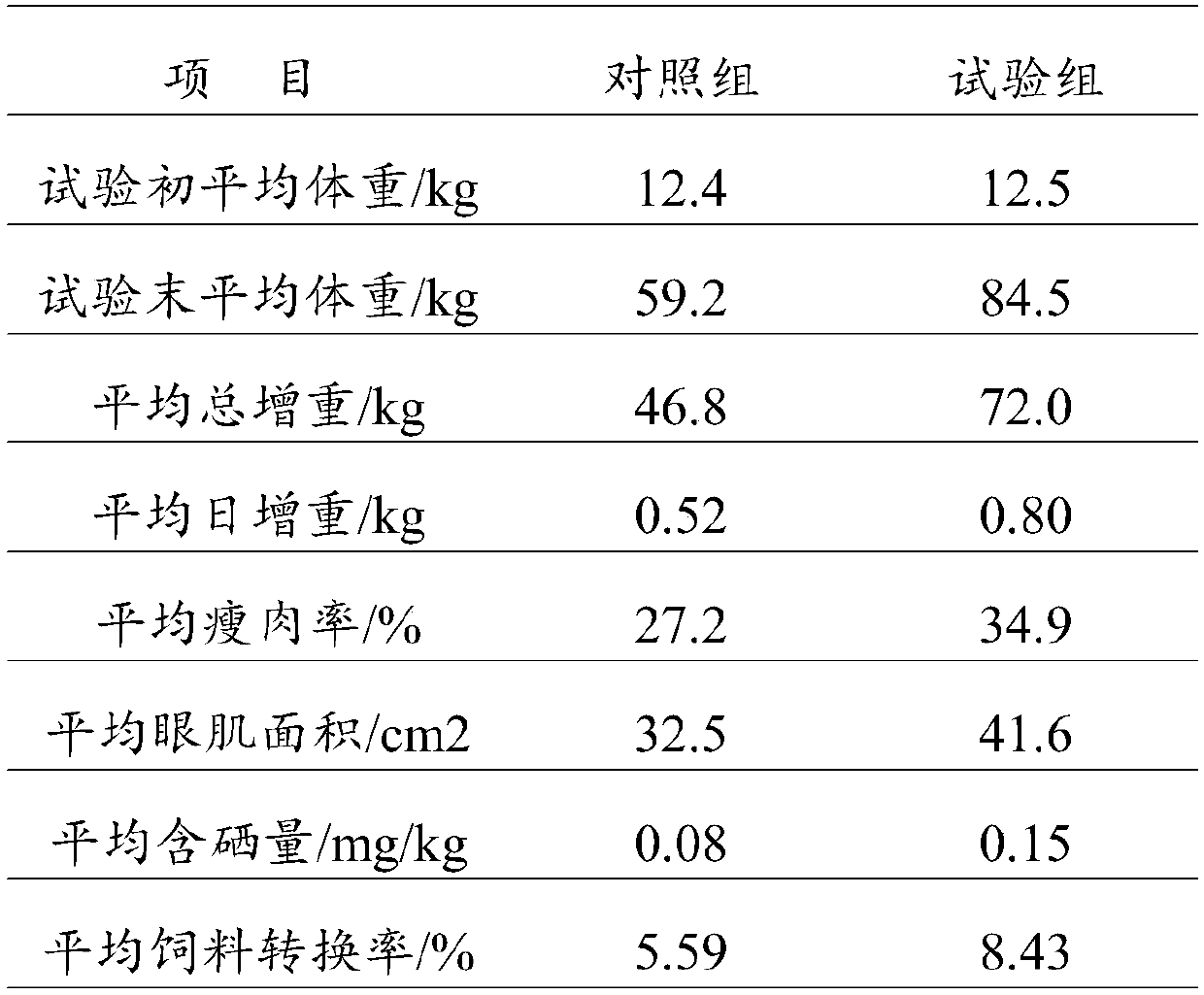

Examples

Embodiment 1

[0048] Weigh 80kg of locust leaves, 80kg of selenium-enriched alfalfa, 60kg of peas, 140kg of banana stems and leaves, 15kg of edible mushroom chaff, 15kg of traditional Chinese medicine additives, 0.1kg of monensin, 0.5kg of rumen-passed methionine, 1kg of yeast powder, and 0.5kg of compound trace elements , multivitamin 0.5kg, molasses 15kg, soybean meal 20kg, calcium hydrogen phosphate 0.1kg, salt 5kg;

[0049] Pulverize locust leaves, selenium-enriched alfalfa, banana leaves, edible fungus chaff and soybean meal into particles with a particle size of 3 cm, mix them uniformly, and dry to a water content of 25% to obtain a fermented premix; fermented premix, pea , molasses, traditional Chinese medicine additives, yeast powder and secondary powder are mixed evenly, and the mixed fermentation material is put into a fermenter for fermentation, and anaerobic fermentation is carried out for 12 hours, and then the fermentation material is ventilated and rolled every 8 hours. When ...

Embodiment 2

[0052] Weigh 82kg of locust leaves, 86kg of selenium-enriched alfalfa, 63kg of peas, 145kg of banana stems and leaves, 17kg of edible mushroom chaff, 18kg of traditional Chinese medicine additives, 0.2kg of monensin, 1.2kg of rumen-passing threonine, 1.4kg of yeast powder, and compound trace Elements 1.1kg, multivitamins 1.2kg, molasses 20kg, soybean meal 25kg, calcium hydrogen phosphate 0.2kg, salt 5.4kg;

[0053] Pulverize locust leaves, selenium-enriched alfalfa, banana leaves, edible fungus chaff and soybean meal into particles with a particle diameter of 4 cm, mix them uniformly, and dry to a water content of 28% to obtain a fermented premix; fermented premix, pea , molasses, traditional Chinese medicine additives, yeast powder and secondary powder are mixed evenly, and the mixed fermentation material is put into a fermenter for fermentation, and anaerobic fermentation is carried out for 14 hours, and then the fermentation material is ventilated and rolled every 9 hours. ...

Embodiment 3

[0056] Weigh 85kg of locust leaves, 90g of selenium-enriched alfalfa, 65kg of peas, 150kg of banana stems and leaves, 20kg of edible mushroom chaff, 20kg of traditional Chinese medicine additives, 0.4kg of monensin, 2kg of rumen-passing lysine, 2kg of yeast powder, and 1.5 kg of compound trace elements. kg, multivitamin 1.5kg, molasses 25kg, soybean meal 30kg, calcium hydrogen phosphate 0.4kg, salt 6kg;

[0057] Pulverize locust leaves, selenium-enriched alfalfa, banana leaves, edible fungus chaff and soybean meal into granules with a particle size of 5 cm, mix them uniformly, and dry to a water content of 30% to obtain a fermented premix; fermented premix, pea , molasses, traditional Chinese medicine additives, yeast powder and secondary powder are mixed evenly, and the mixed fermentation material is put into a fermenter for fermentation, and anaerobic fermentation is first carried out for 16 hours, and then the fermentation material is ventilated and rolled every 10 hours. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com