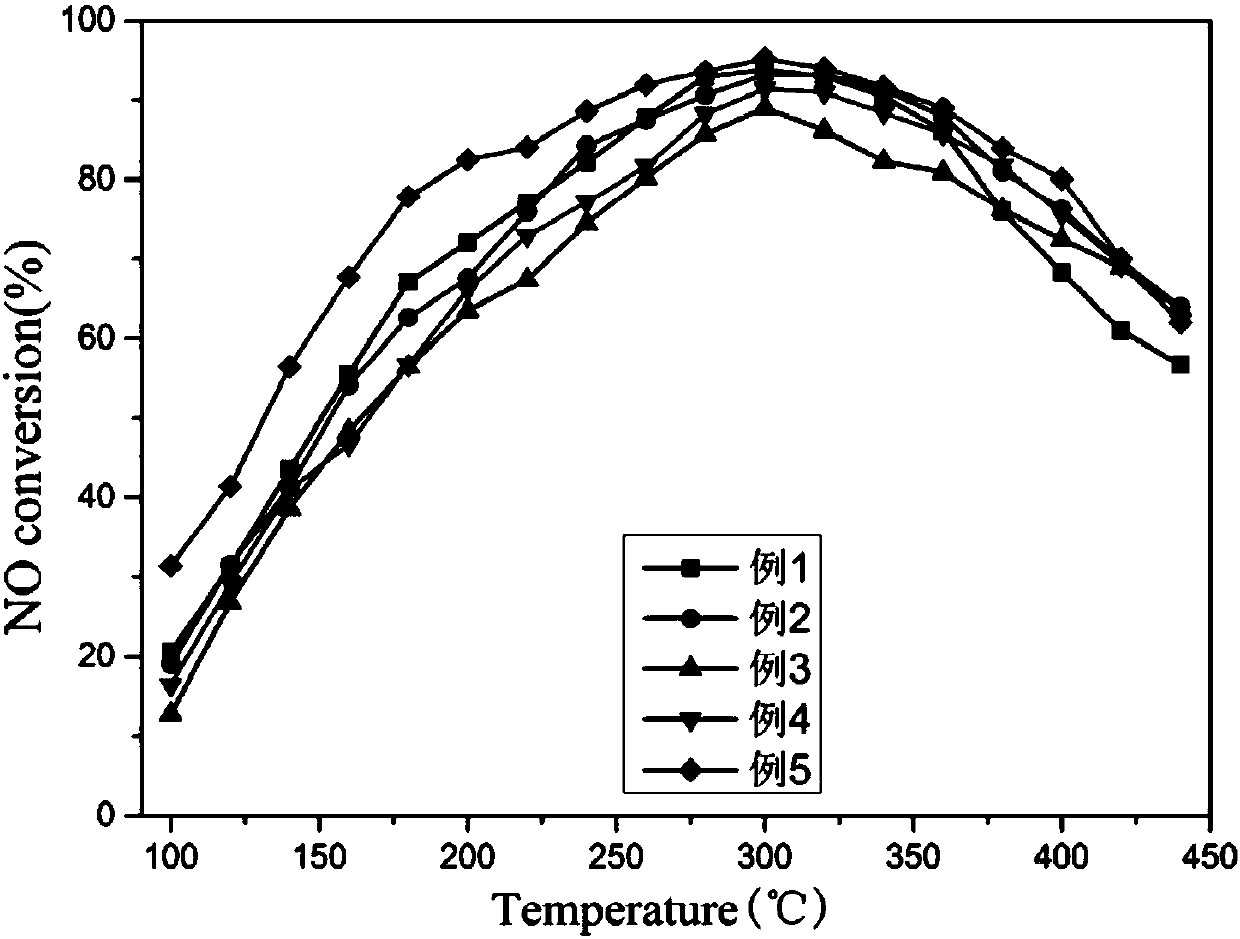

MnOx-FeOx-CuSO4/TiO2 medium-low temperature SCR catalyst and preparation method thereof

An SCR catalyst, mnox-feox-cuso4 technology, applied in the field of denitration catalyst, can solve the problems of pollution, toxicity, restrict the development of nitrogen oxide emission reduction work, etc., to achieve the effect of increasing the specific surface area and facilitating the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

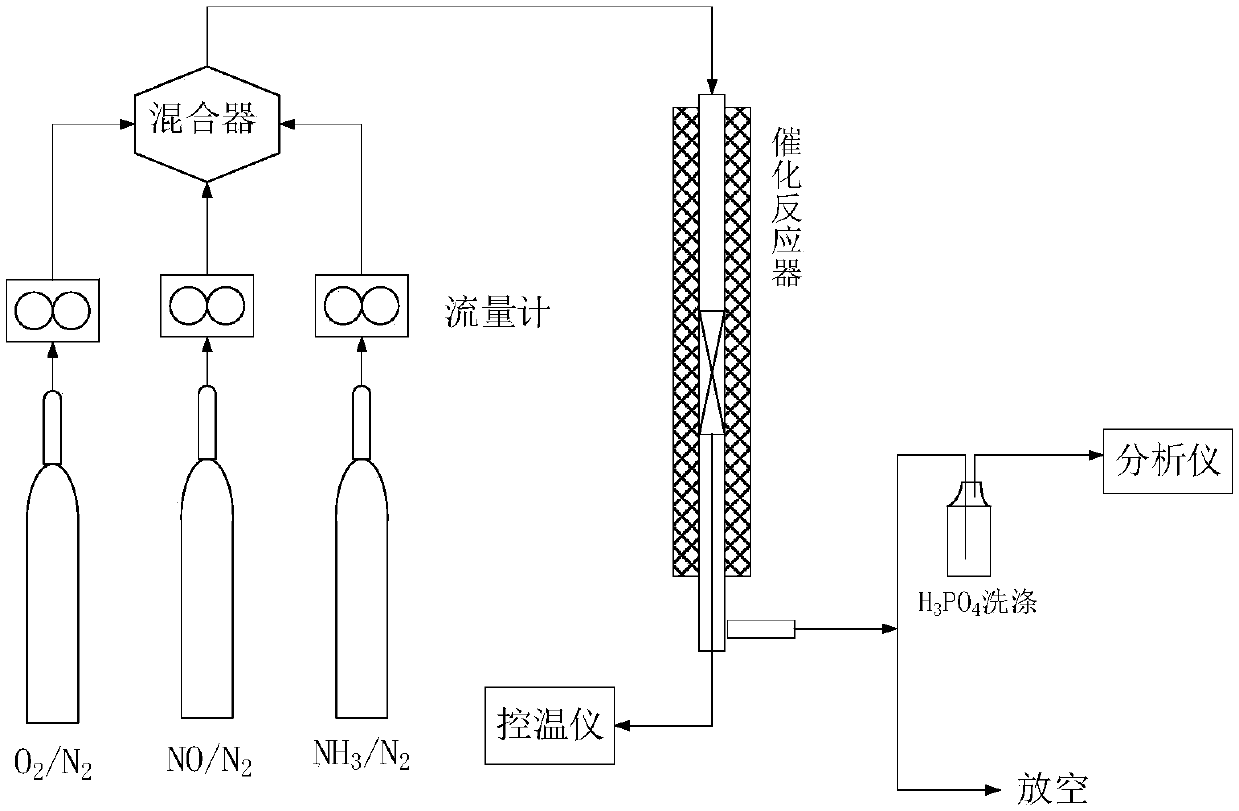

Method used

Image

Examples

Embodiment 1

[0025] (1) Ingredients by weight percentage: cetyltrimethylammonium bromide 0.1kg, tetrabutyl titanate 0.6kg, absolute ethanol 6.8kg, CuSO 4 ·5H 2 O 0.4kg, Mn(Ac) 2 4H 2 O 0.5kg, Fe(NO 3 ) 3 9H 2 O 0.1kg, deionized water 1.5kg;

[0026] (2) After mixing cetyltrimethylammonium bromide, tetrabutyl titanate, and absolute ethanol, adjust the pH of the solution to 5 with glacial acetic acid, and then vigorously stir the above mixture for 1 h to obtain a Ti precursor sol ;

[0027] (3) CuSO 4 ·5H 2 O was added to the Ti precursor sol in step (2) for stirring, and the pH of the solution was adjusted to 4 with glacial acetic acid, and then fully stirred for 2 h under the protection of nitrogen to obtain CuSO 4 / Ti precursor sol;

[0028] (4) Mn(Ac) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O, deionized water is added in the product of step (3) successively, continue to stir 2h under the protection of nitrogen, the obtained mixture is poured into the beaker and then airtight, then agin...

Embodiment 2

[0032] (1) Ingredients by weight percentage: cetyltrimethylammonium bromide 0.5kg, tetrabutyl titanate 8kg, absolute ethanol 63 kg, CuSO 4 ·5H 2 O 5kg, Mn(Ac) 2 4H 2 O 2kg, Fe(NO 3 ) 3 9H 2 O 1.5kg, deionized water 20kg;

[0033] (2) After mixing cetyltrimethylammonium bromide, tetrabutyl titanate, and absolute ethanol, adjust the pH of the solution to 5 with glacial acetic acid, and then vigorously stir the above mixture for 1.5h to obtain a Ti precursor Sol;

[0034] (3) CuSO 4 ·5H 2 O was added to the Ti precursor sol in step (2) for stirring, and the pH of the solution was adjusted to 4 with glacial acetic acid, and then fully stirred for 3 h under the protection of nitrogen to obtain CuSO 4 / Ti precursor sol;

[0035] (4) Mn(Ac) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 O, deionized water is added in the product of step (3) successively, continue to stir 3h under the protection of nitrogen, the obtained mixture is poured into the beaker and airtight, then aging 15h under ...

Embodiment 3

[0039] (1) Ingredients by weight percentage: cetyltrimethylammonium bromide 1.5kg, tetrabutyl titanate 10kg, absolute ethanol 52.5 kg, CuSO 4 ·5H 2 O 6kg, Mn(Ac) 2 4H 2 O 3kg, Fe(NO 3 ) 3 9H 2 O 2kg, deionized water 25kg;

[0040] (2) After mixing cetyltrimethylammonium bromide, tetrabutyl titanate, and absolute ethanol, adjust the pH of the solution to 5 with glacial acetic acid, and then vigorously stir the above mixture for 2 hours to obtain a Ti precursor sol ;

[0041] (3) CuSO 4 ·5H 2 O was added to the Ti precursor sol in step (2) for stirring, and the pH of the solution was adjusted to 4 with glacial acetic acid, and then fully stirred for 3 h under the protection of nitrogen to obtain CuSO 4 / Ti precursor sol;

[0042] (4) Mn(Ac) 2 4H 2 O, Fe(NO 3 ) 3 9H 2 0, deionized water is added in the product of step (3) successively, under the protection of nitrogen, continue to stir 4h, airtight after the gained mixture is poured into beaker, be aging 12h under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com