Bimetal composite electric arc additive manufacturing device and manufacturing method thereof

A technology of additive manufacturing and composite materials, which is applied in manufacturing tools, additive processing, arc welding equipment, etc., and can solve the problems of long production cycle, difficult organization, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

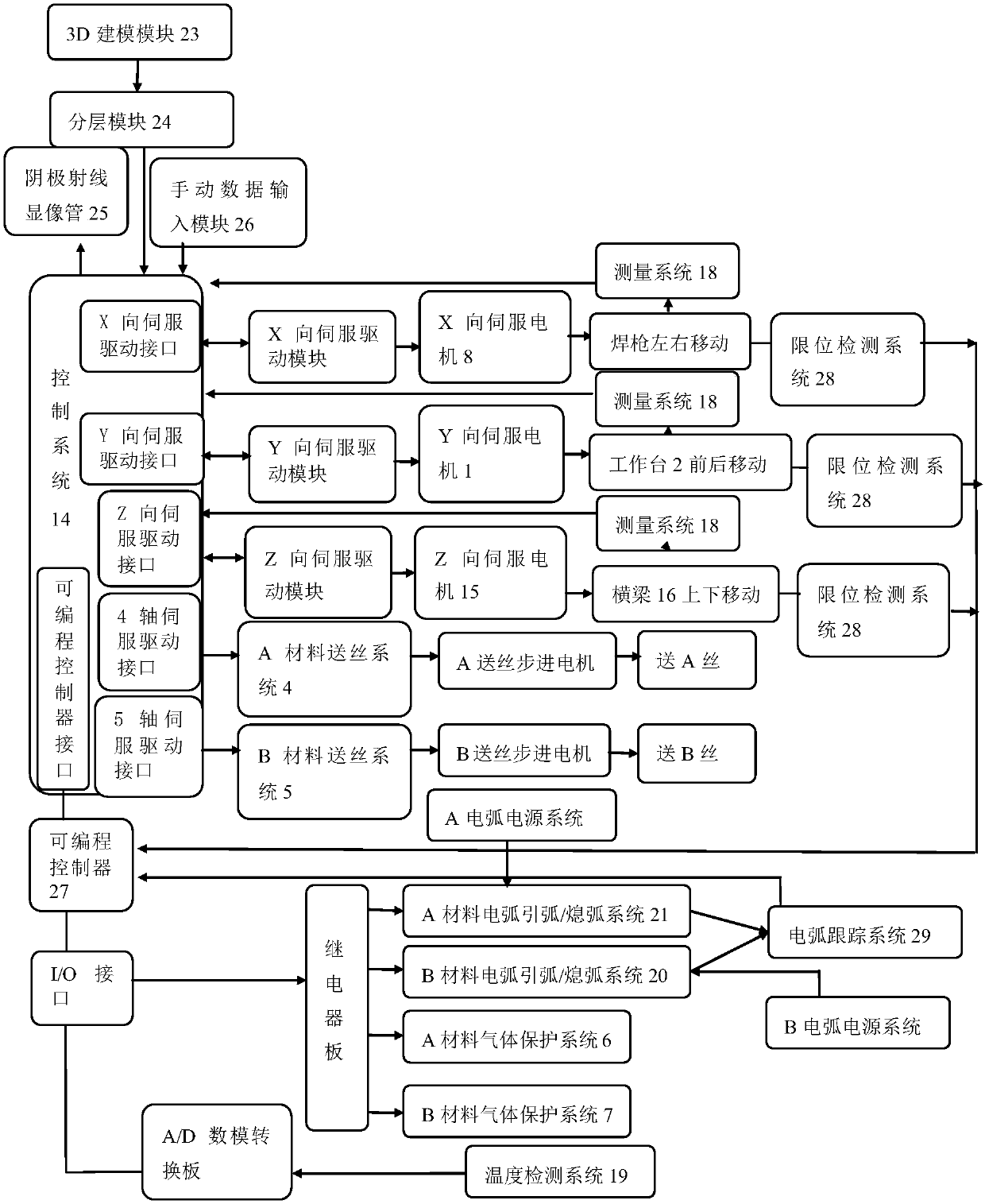

Method used

Image

Examples

Embodiment

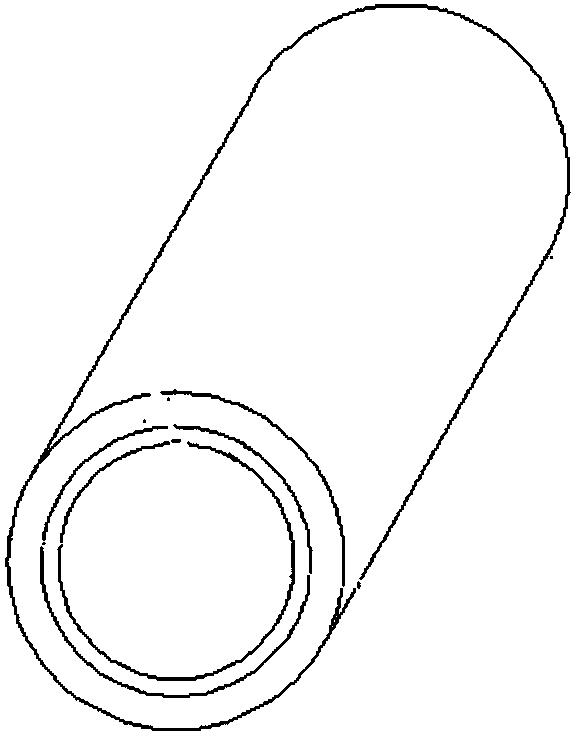

[0119] Taking the arc additive manufacturing of bimetallic composite pipe Φ60mm×(10+2.5)mm×80mm L360 / 625 as an example, such as image 3 As shown, the specific implementation steps of bimetallic composite arc additive manufacturing are illustrated:

[0120] H08C welding wire is selected as the welding wire for arc welding additive base material manufacturing, and the diameter of the welding wire is 1.2mm.

[0121] The arc welding additive cladding wire is selected from UNS N06625 (ERNiCrMo-3), and the wire diameter is 1.2mm.

[0122] 1. 3D modeling: First, the 3D drawing software is used to model the bimetal composite workpiece model. Material A is carbon steel material, and material B is 625 alloy material;

[0123] 2. Layered slicing: First, the 3D model is layered and sliced, and the thickness of the layered slice is calculated and determined according to the accuracy requirements of the part drawing. The thickness of each layer is selected to be 2.5mm, and the layered lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com