Pumping agent for mass concrete

A technology of mass concrete and pumping agent, applied in the field of concrete admixtures, can solve the problems of mass concrete cracking, pump blockage, construction difficulty, etc., and achieve the effects of good retarding effect, low gas content and improving mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

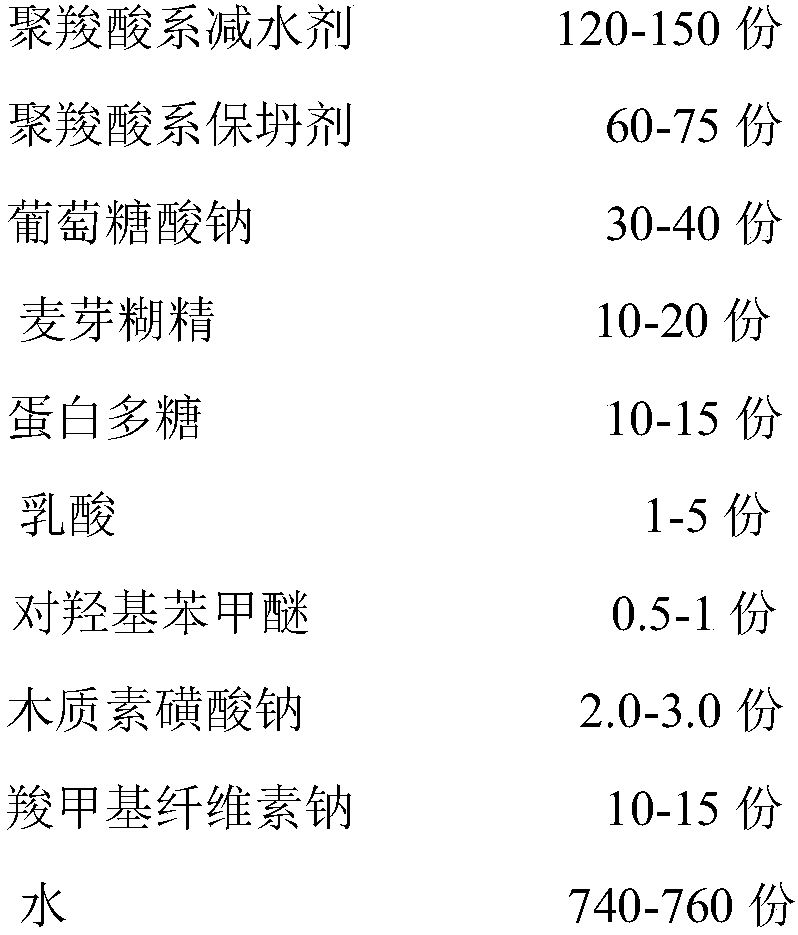

[0025] A concrete pumping agent, characterized in that: the raw materials according to the following parts by weight are fully mixed in a stirring device:

[0026]

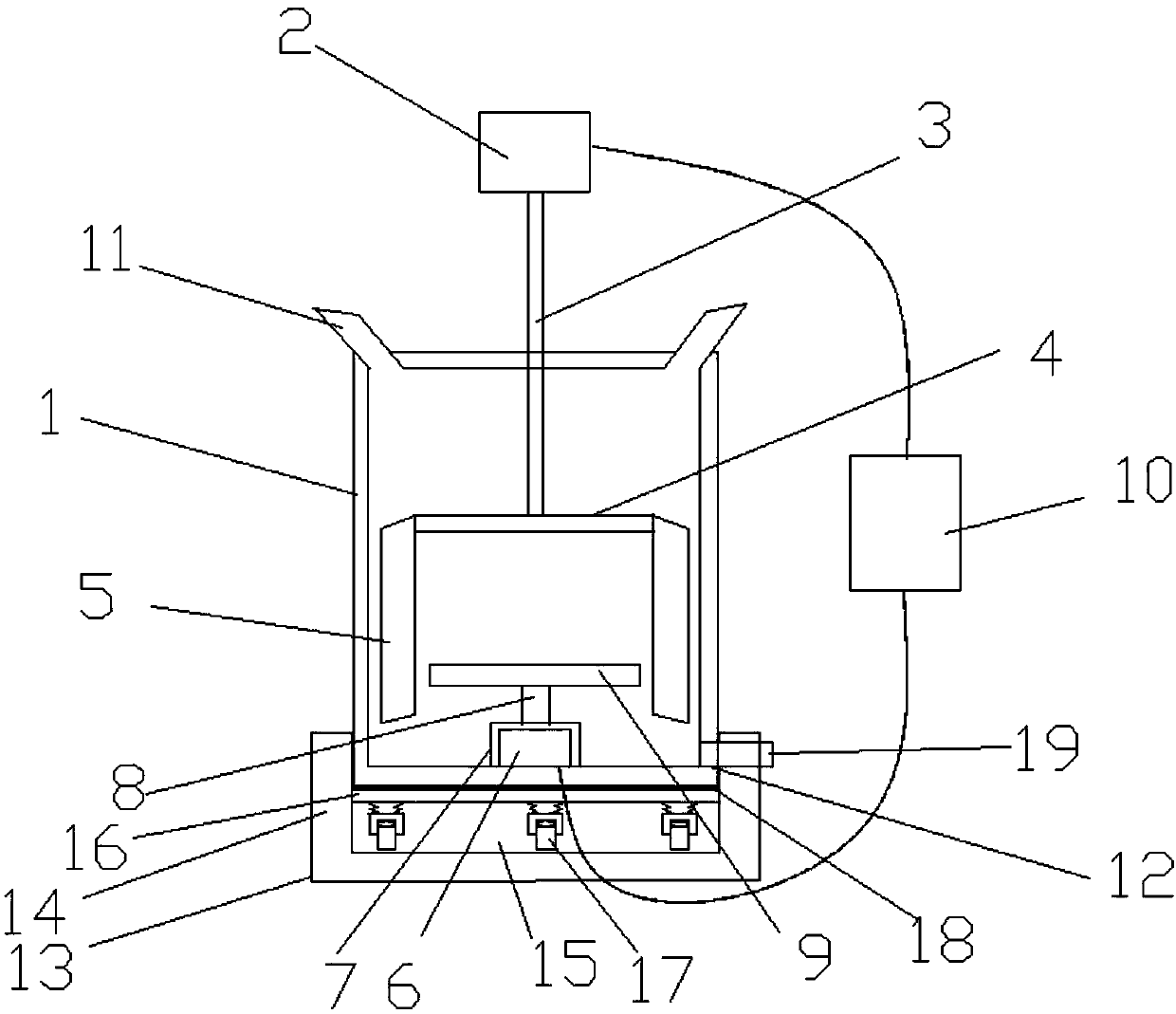

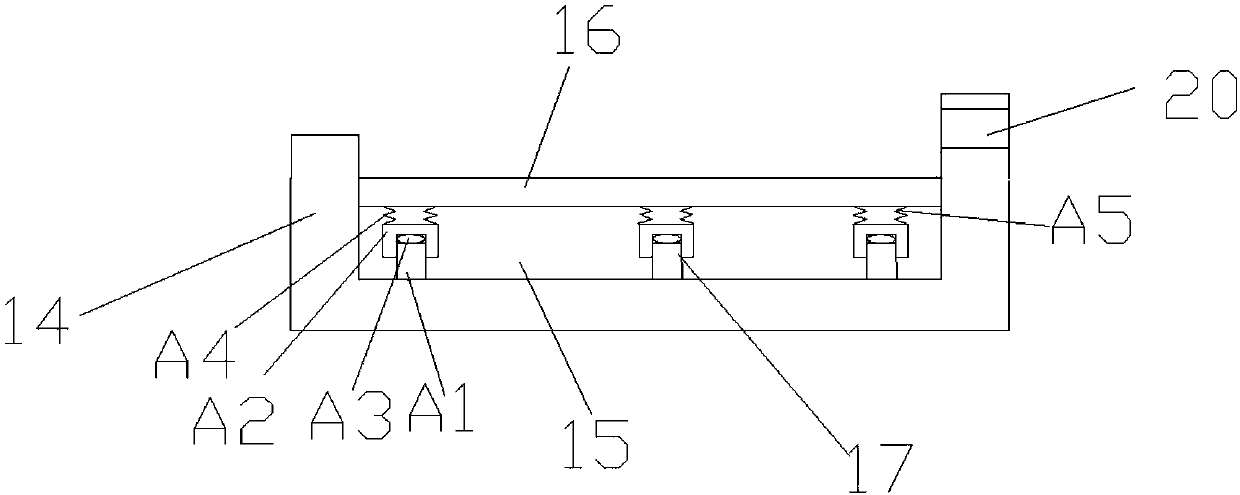

[0027] The stirring device includes a stirring container 1, a first motor 2, a first stirring shaft 3, a first stirring paddle 4, a stirring blade 5, a second motor 6, a second stirring shaft 8, a second stirring paddle 9, and a feeding port 11 , the discharge port 12 and the base, the first motor 2 is supported above the stirring container 1 by a support frame (not shown in the figure), and the downward output shaft of the first motor 2 is connected to the first stirring shaft 3. The first stirring shaft 3 extends into the upper part of the stirring container 1, the bottom end of the first stirring shaft 3 is provided with a first stirring paddle 4, and the first stirring paddle 4 is strip-shaped, and With the first stirring shaft 3 as the axis of symmetry, stirring blades 5 are respectively provided at both e...

Embodiment 1

[0042] The concrete pumping agent is made by fully mixing the following raw materials in the stirring device according to the weight: 1.20kg of polycarboxylate water reducer; 0.60kg of polycarboxylate slump retaining agent; 0.30kg of sodium gluconate; Maltodextrin 0.1kg; proteoglycan 0.10kg; lactic acid 0.01kg; p-hydroxyanisole 0.005kg; sodium lignosulfonate 0.02kg; sodium carboxymethylcellulose 0.1kg; water 7.40kg. The obtained concrete pumping agent is named and numbered 1 # .

[0043]

Embodiment 2

[0045] The concrete pumping agent is made by fully mixing the following raw materials in the stirring device according to the weight: 1.50 kg of polycarboxylic acid-based water reducer; 0.75 kg of polycarboxylic acid-based slump-retaining agent; 0.40 kg of sodium gluconate; Maltodextrin 0.2kg; proteoglycan 0.15kg; lactic acid 0.05kg; p-hydroxyanisole 0.01kg; sodium lignosulfonate 0.03kg; sodium carboxymethylcellulose 0.15kg; water 7.60kg. The obtained concrete pumping agent is named and numbered 2 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com