Preparation method of low temperature-resistant and anti-puncturing geomembrane

A puncture-resistant, geomembrane technology, used in infrastructure engineering, protection devices, gaskets, etc., can solve the problems of membrane fragmentation, rework, loss engineering, etc., achieve strong tensile strength and tear strength, and improve use safety. The effect of improving the anti-seepage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

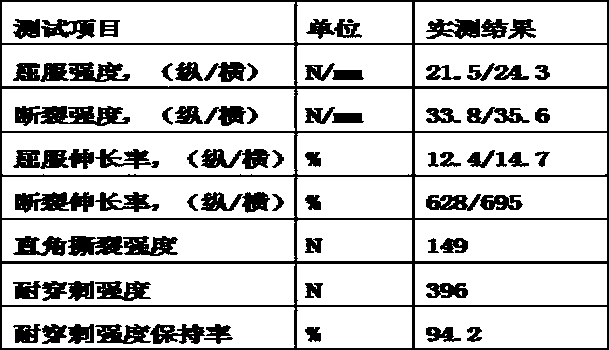

Embodiment 1

[0015] A method for preparing a low-temperature-resistant puncture-resistant geomembrane, comprising the following steps:

[0016] (1) Prepare raw materials by weight: 50 parts of linear low-density polyethylene, 25 parts of high-density polyethylene, 8 parts of elm branch and leaf powder, 16 parts of modified carboxylated nitrile rubber nanocomposite material, 4 parts of filler, 1.5 parts of stabilizer share;

[0017] Wherein, the preparation method of the modified carboxylated nitrile rubber nanocomposite material is: by weight, 8 parts of clay with a particle diameter of 2-20nm are ultrasonically dispersed in deionized water equivalent to 5 times its weight to obtain a suspension, and the Add 2.4 parts of zinc oxide, 1.6 parts of hexamethylene diisocyanate, and 0.5 parts of sulfur to the suspension, stir for 1.5 hours at a temperature of 80°C, then add 45 parts of nitrile rubber latex, After stirring for 1.5 hours, add a flocculant to flocculate, obtain a modified carboxyl...

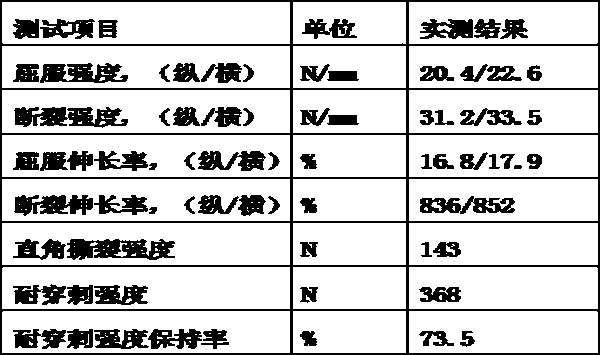

Embodiment 2

[0026] A method for preparing a low-temperature-resistant puncture-resistant geomembrane, comprising the following steps:

[0027] (1) Prepare raw materials by weight: 45 parts of linear low-density polyethylene, 22 parts of high-density polyethylene, 6 parts of elm branch and leaf powder, 14 parts of modified carboxylated nitrile rubber nanocomposite material, 6 parts of filler, 1 part of stabilizer share;

[0028] Wherein, the preparation method of the modified carboxylated nitrile rubber nanocomposite material is as follows: by weight, 6 parts of clay with a particle diameter of 2-20nm are ultrasonically dispersed in deionized water equivalent to 4 times its weight to obtain a suspension. Add 2.2 parts of zinc oxide, 1.4 parts of hexamethylene diisocyanate, and 0.2 parts of sulfur to the suspension, stir for 2 hours at a temperature of 85°C, then add 50 parts of nitrile rubber latex, After stirring for 2 hours, add a flocculant to flocculate, obtain a modified carboxylated...

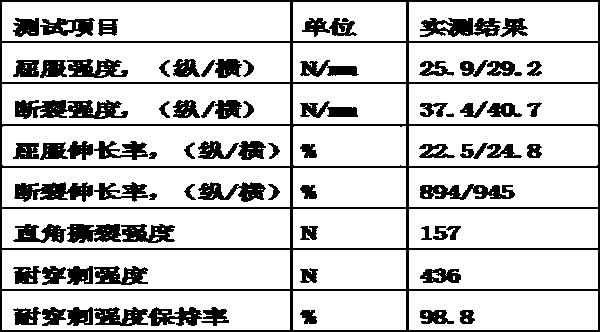

Embodiment 3

[0036] A method for preparing a low-temperature-resistant puncture-resistant geomembrane, comprising the following steps:

[0037] (1) Prepare raw materials by weight: 55 parts of linear low-density polyethylene, 28 parts of high-density polyethylene, 10 parts of elm branch and leaf powder, 20 parts of modified carboxylated nitrile rubber nanocomposites, 2 parts of filler, 2 parts of stabilizer share;

[0038] Wherein, the preparation method of the modified carboxylated nitrile rubber nanocomposite material is: by weight, 10 parts of clay with a particle diameter of 2-20nm is ultrasonically dispersed in deionized water equivalent to 6 times its weight to obtain a suspension, and the Add 2.6 parts of zinc oxide, 1.8 parts of hexamethylene diisocyanate, and 0.8 parts of sulfur to the suspension, stir for 1 hour at a temperature of 75°C, then add 40 parts of nitrile rubber latex, After stirring for 1 hour, add a flocculant to flocculate, obtain a modified carboxylated nitrile ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com