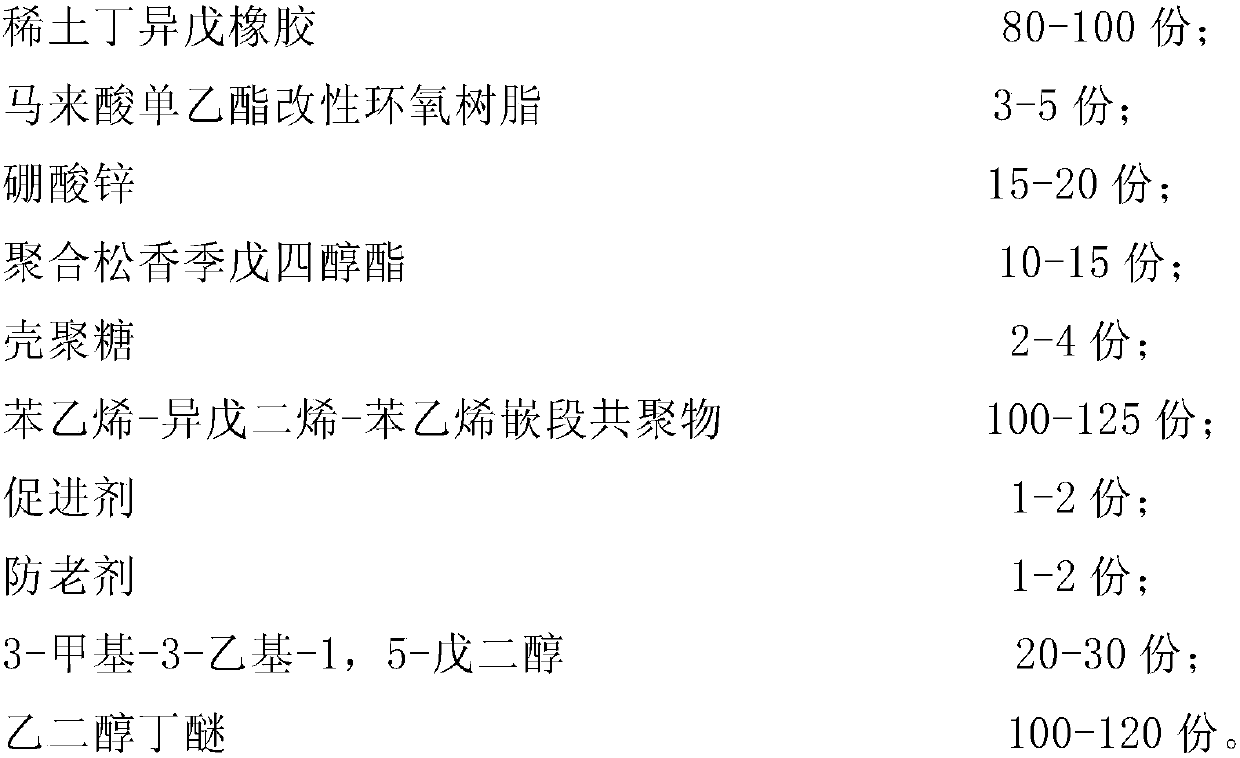

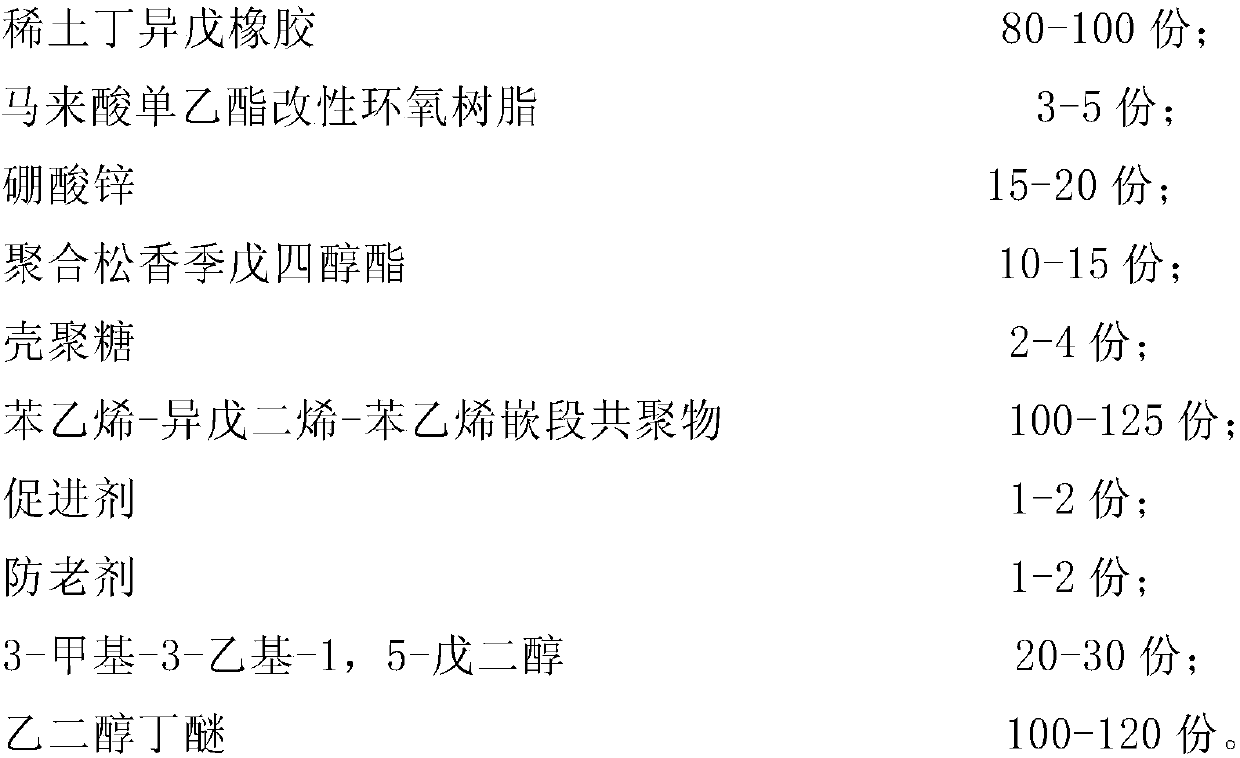

Solvent type adhesive

An adhesive and solvent-based technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low solid content, poor cold resistance, etc., to improve antifreeze performance, enhance resistance Thermal, anti-oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

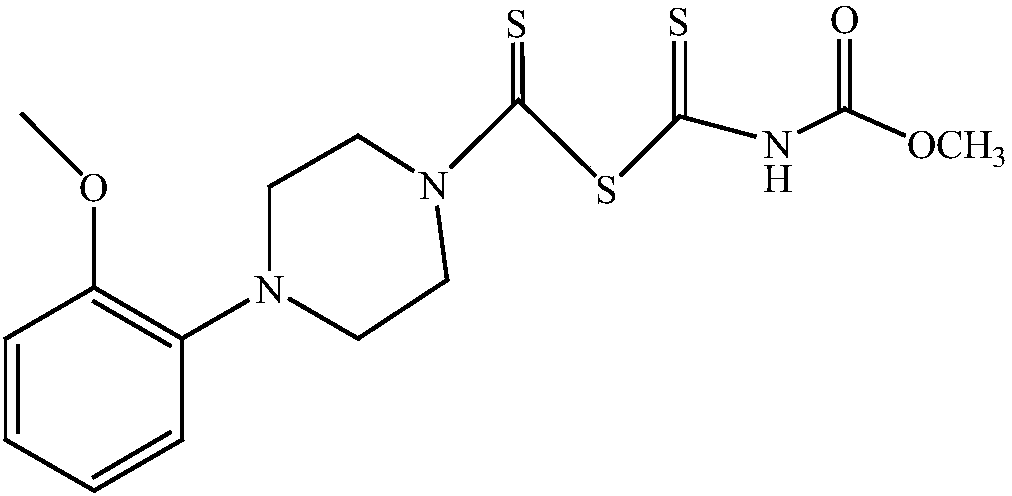

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0019] Rare earth butyl isoprene rubber has excellent corrosion resistance and excellent adhesion, the Mooney viscosity is 60-70ML(1+4)100℃, and the weight average relative molecular mass is 160×10 -4 -200×10 -4 , under this relative molecular mass and viscosity, the cross-linked structure of rare earth butadiene-isoprene rubber is relatively perfect and uniform, with many entangled structures, high cohesive energy density of polymer chains, high energy consumption for tensile fracture, and high tensile strength. And high viscosity, excellent wear performance.

[0020] There is a small amount of isoprene chains in the styrene-isoprene-styrene block copolymer, which can improve the low temperature resistance of the adhesive. And has good elasticity and bonding strength.

[0021] Rare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com