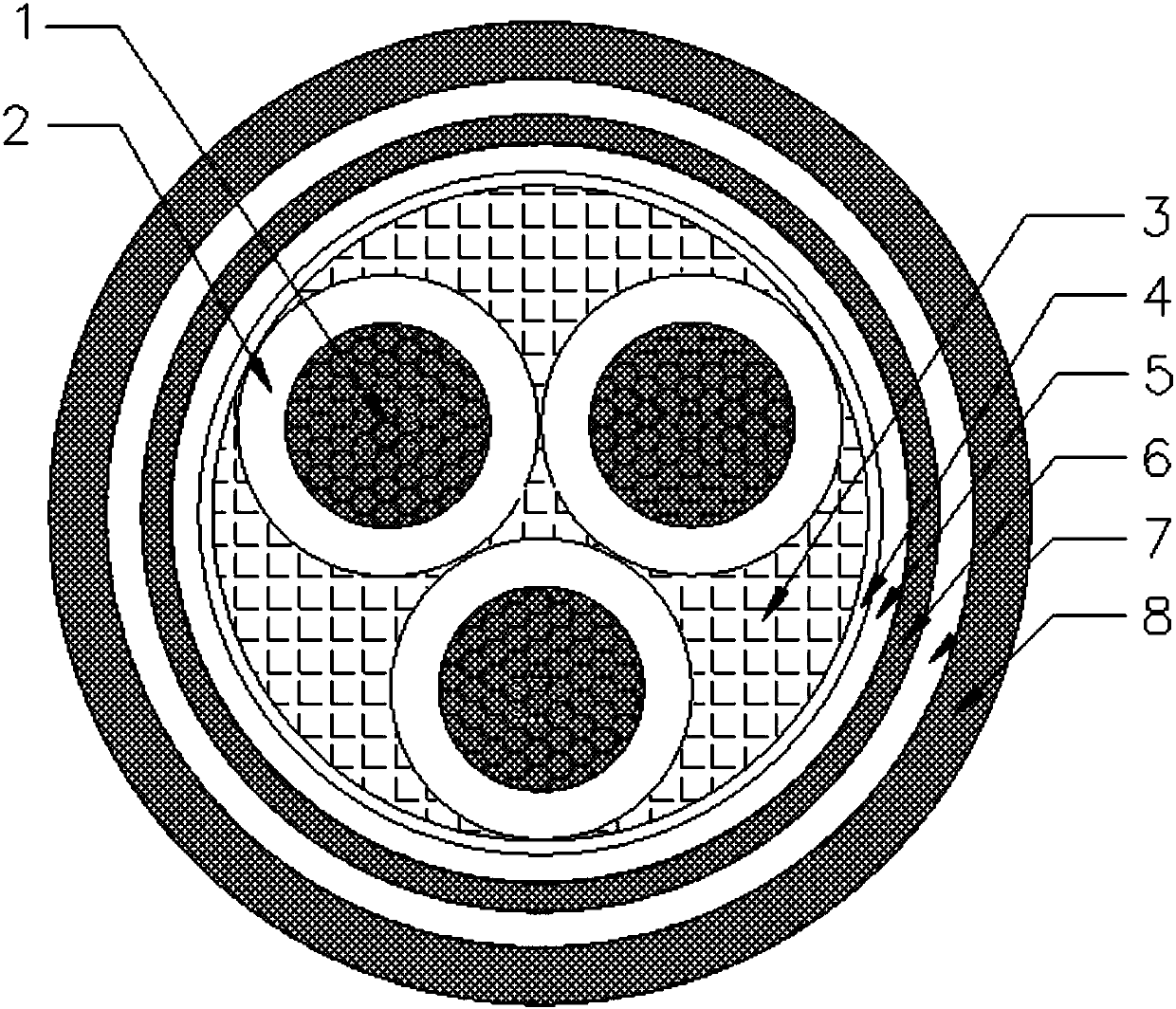

Environmental-protection heat-insulation medium-voltage crosslinked flexible fireproof cable with metal steel sheath

A technology of fireproof cable and steel sheath, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of high cost of cables, unsuitable for promotion and use, inability to meet safety and environmental protection, etc., and achieve the effect of meeting environmental performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The cable core of this embodiment is made of insulated wire cores. The gap between the cable cores is provided with a flame-retardant silicone rubber rope filling layer. Chemical refractory silicone rubber heat insulation layer. Outside the heat insulation layer, there are extruded ceramic halogen-free low-smoke flame-retardant polyolefin refractory inner lining and stainless steel interlocking armored metal sheath protection layer. The outermost layer of the cable is Extrusion of ceramicized halogen-free low-smoke flame-retardant polyolefin refractory material.

[0060] 1. The conductor is made of Φ8.00 oxygen-free copper rod, which is drawn into a round copper single wire after multi-stretching. After drawing and annealing, the conductor is normally stranded to ensure the stability of the conductor structure. The pitch ratio of each stranded layer is determined. Ensure the bending performance and tightness of the conductor.

[0061] 2. The insulating layer adopts per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com