Magnetic tunnel junction with high perpendicular magnetic anisotropy

A magnetic tunnel junction, anisotropic technology, applied in the field of non-volatile magnetic memory and magnetic logic, can solve the requirement of long-term reliable storage of data, low storage density of magnetic random access memory, and low spin transfer torque reversal efficiency and other problems, to achieve the effect of high spin transfer torque inversion efficiency, strong perpendicular magnetic anisotropy, and small cross-sectional size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

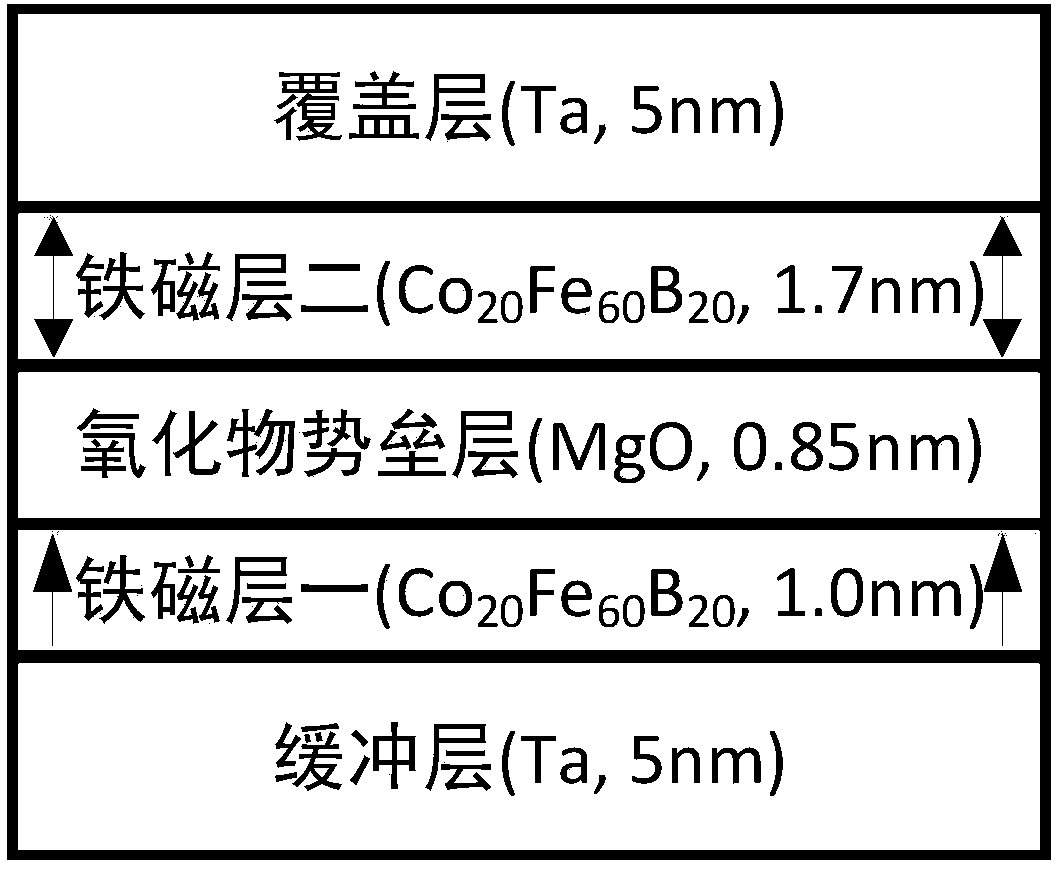

[0042] In this embodiment, the buffer layer, the ferromagnetic layer 1, the barrier layer, the ferromagnetic layer 2 and the cover layer are deposited on the thermally oxidized silicon substrate in the order from bottom to top by magnetron sputtering, such as Figure 4A shown. Among them, the material of the buffer layer is Ta, the thickness is 5nm; the material of the ferromagnetic layer is Co 20 Fe 60 B 20 , the thickness is 20nm; the material of the barrier layer is MgO, the thickness is 1nm; the material of the ferromagnetic layer 2 is Co 20 Fe 60 B 20 , with a thickness of 30nm; the material of the covering layer is Ta, with a thickness of 5nm. Finally, processing such as photolithography and etching is performed, and the cross-sectional shape is circular with a diameter of 10 nm. The buffer layer can have functions such as reducing surface roughness and promoting the formation of the growth crystal direction of the multilayer film, and the covering layer can have f...

Embodiment 2

[0048] In this embodiment, the buffer layer, the ferromagnetic layer 1, the barrier layer, the ferromagnetic layer 2 and the cover layer are deposited on the thermally oxidized silicon substrate in the order from bottom to top by magnetron sputtering, such as Figure 4B shown. Among them, the material of the buffer layer is Ta, the thickness is 5nm; the material of the ferromagnetic layer is Co 20 Fe 60 B 20 , the thickness is 30nm; the material of the barrier layer is MgO, the thickness is 1nm; the material of the ferromagnetic layer 2 is Co 20 Fe 60 B 20, with a thickness of 20nm; the material of the covering layer is Ta, with a thickness of 5nm. Finally, processing such as photolithography and etching is performed, and the cross-sectional shape is circular with a diameter of 10 nm. The buffer layer can have functions such as reducing surface roughness and promoting the formation of the growth crystal direction of the multilayer film, and the covering layer can have fu...

Embodiment 3

[0054] In this embodiment, the buffer layer, the ferromagnetic layer 1, the barrier layer, the ferromagnetic layer 2 and the covering layer are deposited on the thermally oxidized silicon substrate in sequence from bottom to top by magnetron sputtering. Wherein, the material of buffer layer is W, and the thickness is 8nm; The material of ferromagnetic layer 1 is Co 40 Fe 40 B 20 , the thickness is 100nm; the material of barrier layer is MgO, the thickness is 1.5nm; the material of ferromagnetic layer 2 is Co 40 Fe 40 B 20 , with a thickness of 120nm; the material of the covering layer is W, with a thickness of 5nm. Finally, photolithography, etching and other processing are performed, and the cross-sectional shape is circular with a diameter of 1nm. The buffer layer can have functions such as reducing surface roughness and promoting the growth crystal orientation of the multilayer film, and the covering layer can have functions such as anti-oxidation and reducing surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com