Ore selecting method for lowering content of magnesium oxide in Nelson reselection precious metal concentrates

A mineral processing method and precious metal technology, applied in flotation, solid separation, etc., can solve problems such as pollution, unsatisfactory test indicators, and high energy consumption, and achieve the effects of simple process flow, convenient purchase, and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

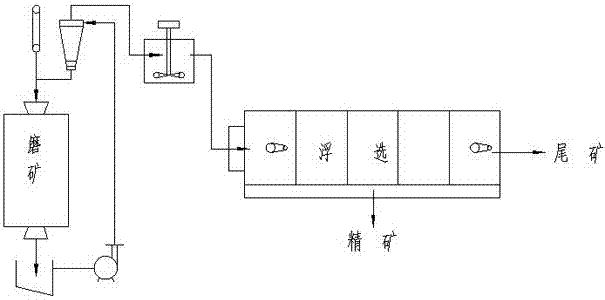

Method used

Image

Examples

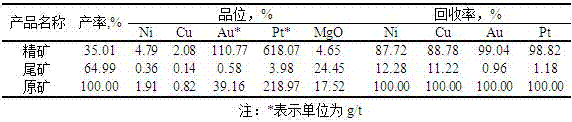

Embodiment 1

[0013] The Nelson re-selection precious metal concentrate produced by the Nelson system in the first dressing workshop of a certain factory is processed as follows:

[0014] A. One-stage grinding: Grinding the Nelson gravity-selected precious metal concentrate through a ball mill. During the grinding, the ball mill discharges ore and is classified by the cyclone, and the sand is returned to the ball mill, and the overflow is fed into the mixing tank. The particle size of the overflow product is - 0.074mm accounts for 60-75%, copper sulfate is added during the grinding process and the amount of copper sulfate added is 80g / t Nelson gravity-selected precious metal concentrate;

[0015] B. One-stage open-circuit flotation: After grinding, add flotation agents to the Nelson gravity-selected precious metal concentrate in the mixing tank. The flotation agents are butyl xanthate, foaming agent and ammonium butyl ammonium. The J-622 produced by Baiyin Pharmaceutical Factory of Metallur...

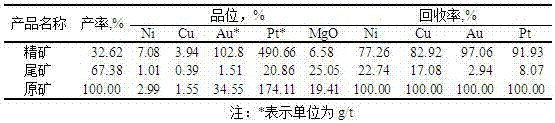

Embodiment 2

[0021] The Nelson gravity separation precious metal concentrate produced by the Nelson system in the second beneficiation workshop of a factory is processed as follows:

[0022] A. One-stage grinding: Grinding the Nelson gravity-selected precious metal concentrate through a ball mill. During the grinding, the ball mill discharges ore and is classified by the cyclone, and the sand is returned to the ball mill, and the overflow is fed into the mixing tank. The particle size of the overflow product is - 0.074mm accounts for 60-75%, copper sulfate is added during the grinding process and the amount of copper sulfate added is 90g / t Nelson gravity-selected precious metal concentrate;

[0023] B. One-stage open-circuit flotation: After grinding, add flotation agents to the Nelson gravity-selected precious metal concentrate in the mixing tank. The flotation agents are butyl xanthate, foaming agent and ammonium butyl ammonium. The J-622 produced by Baiyin Pharmaceutical Factory of Meta...

Embodiment 3

[0029] The Nelson re-separation precious metal concentrate produced by the Nelson system in the third beneficiation workshop of a factory is processed as follows:

[0030] A. One-stage grinding: Grinding the Nelson gravity-selected precious metal concentrate through a ball mill. During the grinding, the ball mill discharges ore and is classified by the cyclone, and the sand is returned to the ball mill, and the overflow is fed into the mixing tank. The particle size of the overflow product is - 0.074mm accounts for 60-75%, copper sulfate is added during the grinding process and the amount of copper sulfate added is 100g / t Nelson gravity-selected precious metal concentrate;

[0031] B. One-stage open-circuit flotation: After grinding, add flotation agents to the Nelson gravity-selected precious metal concentrate in the mixing tank. The flotation agents are butyl xanthate, foaming agent and ammonium butyl ammonium. The J-622 produced by Baiyin Pharmaceutical Factory of Metallurg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com