Hard alloy valve seat turning tool and application thereof

A technology of cemented carbide and solid carbide, which is applied in the direction of cutting tools for lathes, turning equipment, tool holder accessories, etc., can solve the problems of tool wear, low production efficiency, high cutting temperature, etc., and achieve the improvement of tool life , long service life and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of cemented carbide valve seat turning tool material of the present invention adopts fine-grained cemented carbide, grain size≤0.5 μm; For example: material is T10MG (Germany TIGRA brand), and T10MG is that grain size is 0.5 μm, contains Fine-grained cemented carbide material with 10% cobalt content: the hardness is 92.5HRA, the bending strength is 3800N / mm2, and the strength is 512psi.

[0031] Described cemented carbide valve seat turning tool adopts solid carbide; The solid carbide valve seat turning tool can be repaired and reused.

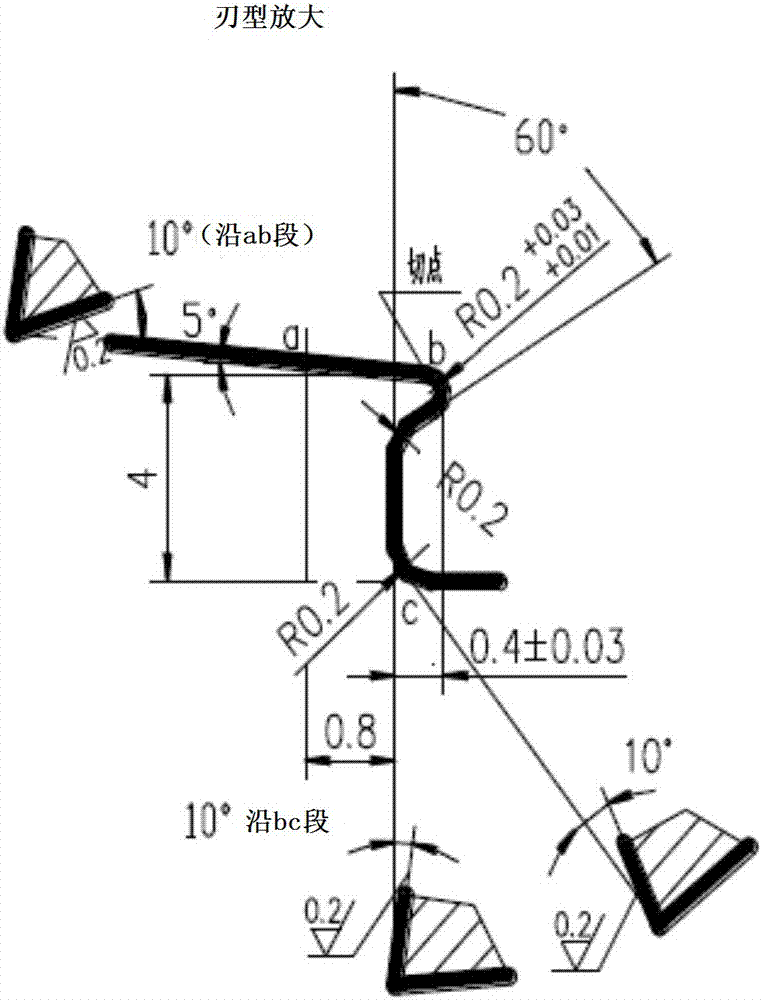

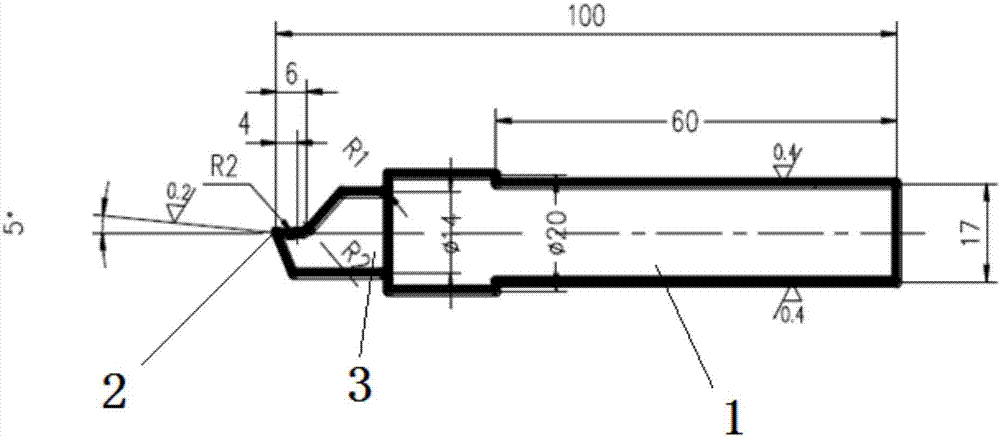

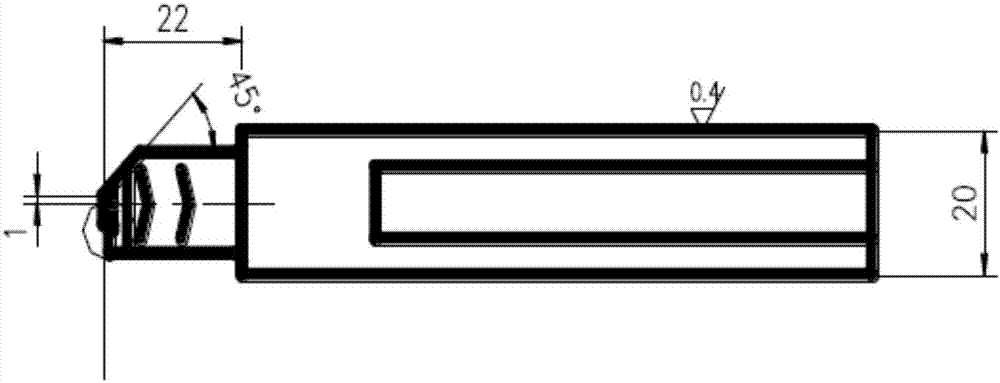

[0032] Such as figure 1 and figure 2 As shown, the handle 1 has upper and lower planes, which are convenient for clamping; the rake edge 2 is parallel to the plane of the handle 1 to ensure that the cutting position of the tool is correct after the tool is clamped; the neck 3 is a slender rod, which is convenient for clamping. Deep hole processing with small hole diameter of valve seat. The rake angle of the turning tool is 5...

Embodiment 2

[0038] A kind of cemented carbide valve seat turning tool material of the present invention adopts fine-grained cemented carbide, and grain size≤0.5 μ m;

[0039] Described cemented carbide valve seat turning tool adopts solid carbide; The solid carbide valve seat turning tool can be repaired and reused.

[0040] Such as figure 1 and figure 2 As shown, the handle 1 has upper and lower planes, which are convenient for clamping; the rake edge 2 is parallel to the plane of the handle 1 to ensure that the cutting position of the tool is correct after the tool is clamped; the neck 3 is a slender rod, which is convenient for clamping. Deep hole processing with small hole diameter of valve seat. The rake angle of the turning tool is 6°, and the back angle of the turning tool is 11° along the profile.

[0041] The hard alloy valve seat turning tool of the present invention is coated with a coating, and the coating adopts a nanometer blue coating.

[0042]When described cemented c...

Embodiment 3

[0045] A kind of cemented carbide valve seat turning tool material of the present invention adopts fine-grained cemented carbide, and grain size≤0.5 μm;

[0046] Described cemented carbide valve seat turning tool adopts solid carbide; The solid carbide valve seat turning tool can be repaired and reused.

[0047] like figure 1 and figure 2 As shown, the handle 1 has upper and lower planes, which are convenient for clamping; the rake edge 2 is parallel to the plane of the handle 1 to ensure that the cutting position of the tool is correct after the tool is clamped; the neck 3 is a slender rod, which is convenient for clamping. Deep hole processing with small hole diameter of valve seat. The rake angle of the turning tool is 7°, and the back angle of the turning tool is 12° along the profile.

[0048] The hard alloy valve seat turning tool of the present invention is coated with a coating, and the coating adopts a nanometer blue coating.

[0049] When described cemented carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com