A kind of preparation method of high-strength carbon airgel

A carbon airgel, high-strength technology, applied in the direction of nano-carbon, can solve the problems of carbon airgel composite material cracks, affecting material strength and performance, low mechanical strength, etc., to achieve improved cohesion, excellent toughness, and mechanical strength. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

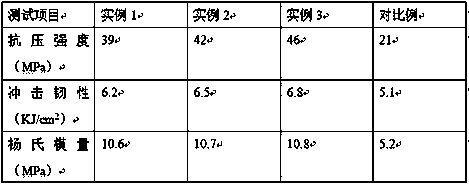

Examples

example 1

[0025] Weighing fresh lotus root, removing the joints, putting it into a tissue grinder and pulverizing for 30 minutes to obtain ground lotus root, then mixing the ground lotus root with water at a mass ratio of 1:3, grinding and pulverizing with a stone mill, and obtaining lotus root pulp; Rinse the above-mentioned lotus root slurry with water for 2 days, stir once a day, remove the upper layer of lotus root residue and the lower layer of sediment after the lotus root slurry is clarified, and obtain the middle layer of lotus root starch slurry, then put the lotus root slurry into a gauze bag, hang it and drain it naturally, Take out the drained lotus root powder, spread it flat on a stainless steel tray, and dry it in the sun until the moisture content of the lotus root powder is 3%, that is, the self-made lotus root powder; weigh the loofah and put it in a jet mill for 20 minutes to obtain loofah fragments. Mix the above-mentioned self-made lotus root powder and warm water at...

example 2

[0027]Weighing fresh lotus root, removing the joints, putting it into a tissue grinder and pulverizing for 35 minutes to obtain ground lotus root, then mixing the ground lotus root with water at a mass ratio of 1:3, grinding and pulverizing with a stone mill, and obtaining lotus root pulp; Rinse the above-mentioned lotus root slurry with water for 2 days, stir once a day, remove the upper layer of lotus root residue and the lower layer of sediment after the lotus root slurry is clarified, and obtain the middle layer of lotus root starch slurry, then put the lotus root slurry into a gauze bag, hang it and drain it naturally, Take out the drained lotus root powder, spread it flat on a stainless steel tray, and dry it in the sun until the moisture content of the lotus root powder is 4%, that is, the homemade lotus root powder; weigh the loofah and put it in a jet mill for 25 minutes to obtain loofah fragments. Mix the above-mentioned self-made lotus root powder and warm water at 2...

example 3

[0029] Weighing fresh lotus root, removing the joints, putting it into a tissue grinder and pulverizing for 40 minutes to obtain ground lotus root, then mixing the ground lotus root with water at a mass ratio of 1:3, grinding and pulverizing with a stone mill, and obtaining lotus root pulp; Rinse the above-mentioned lotus root slurry with water for 3 days, stir once a day, remove the upper layer of lotus root residue and the lower layer of sediment after the lotus root slurry is clarified, and obtain the middle layer of lotus root starch slurry, then put the lotus root slurry into a gauze bag, hang it and drain it naturally, Take out the drained lotus root powder, spread it flat on a stainless steel tray, and dry it in the sun until the moisture content of the lotus root powder is 5%, that is, the self-made lotus root powder; weigh the loofah and put it in a jet mill for 30 minutes to obtain loofah fragments. Mix the above-mentioned self-made lotus root powder and warm water at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com