Luminous printing colorant and preparation method thereof

A printing color paste and rare earth luminescence technology, applied in the field of textile printing and dyeing, can solve the problems of loss of color saturation and easy falling off, and achieve the effect of meeting the requirements of environmental protection standards and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

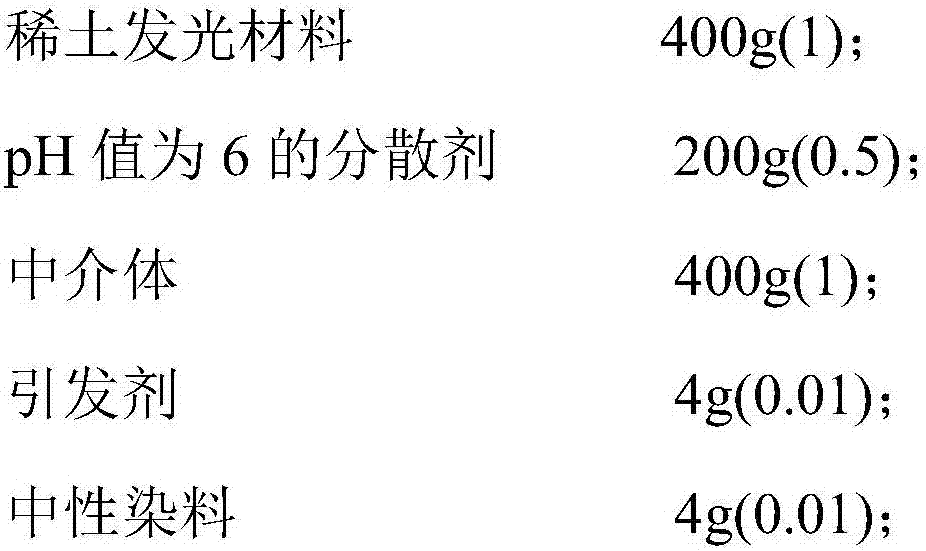

[0024] A luminous printing paste, comprising the following components:

[0025]

[0026]

[0027] Wherein, the rare earth luminescent material is Sr(NO 3 ) 2 Rare earth luminescent material, the rare earth luminescent material described in other embodiments can also be Al(NO 3 ) 3 9H 2 O, Eu 2 o 3 and Dy 2 o 3 one or more of.

[0028] Wherein, the dispersant is a polymer dispersant, and the dispersant in other embodiments can also be a synthetic polymer, polyvalent carboxylic acid, coupling agent, silicate, the dispersant The pH value is 6-7.

[0029] Wherein, the intermediary is polyurethane polymer. The intermediary in other embodiments may also be an acrylic polymer.

[0030] Wherein, the initiator is sodium persulfate. The initiator described in other embodiments can also be ammonium persulfate or acyl anhydride group.

[0031] Wherein, the dye is a neutral dye. The dyes described in other embodiments can also be acid complex dyes.

[0032] Wherein, th...

Embodiment 2

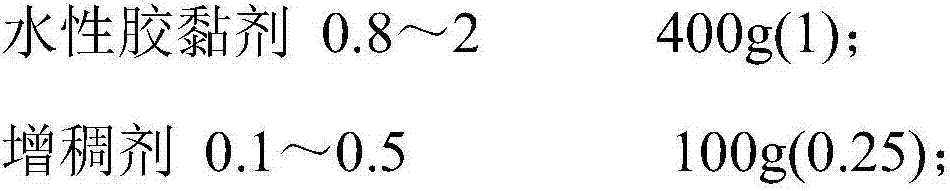

[0038] A luminous printing paste, comprising the following components:

[0039]

[0040] Wherein, the rare earth luminescent material is Sr(NO 3 ) 2 Rare earth luminescent materials. The dispersant is a polymer dispersant. The intermediary is polyurethane polymer. The intermediary in other embodiments may also be an acrylic polymer. The initiator is ammonium persulfate. The dye is an acid complex dye. The water-based adhesive is a polyvinyl alcohol-based water-based adhesive. The thickener is a polyacrylic compound thickener.

[0041] The preparation method of the luminous printing paste of the present invention comprises the following steps:

[0042] a. Add dispersants, intermediaries and dyes to rare earth luminescent materials, and mix them evenly to form a color paste;

[0043] b. Before production on the machine, add water-based adhesive and thickener to the color paste, and stir evenly to obtain the luminous printing color paste, so that the luminous printing...

Embodiment 3

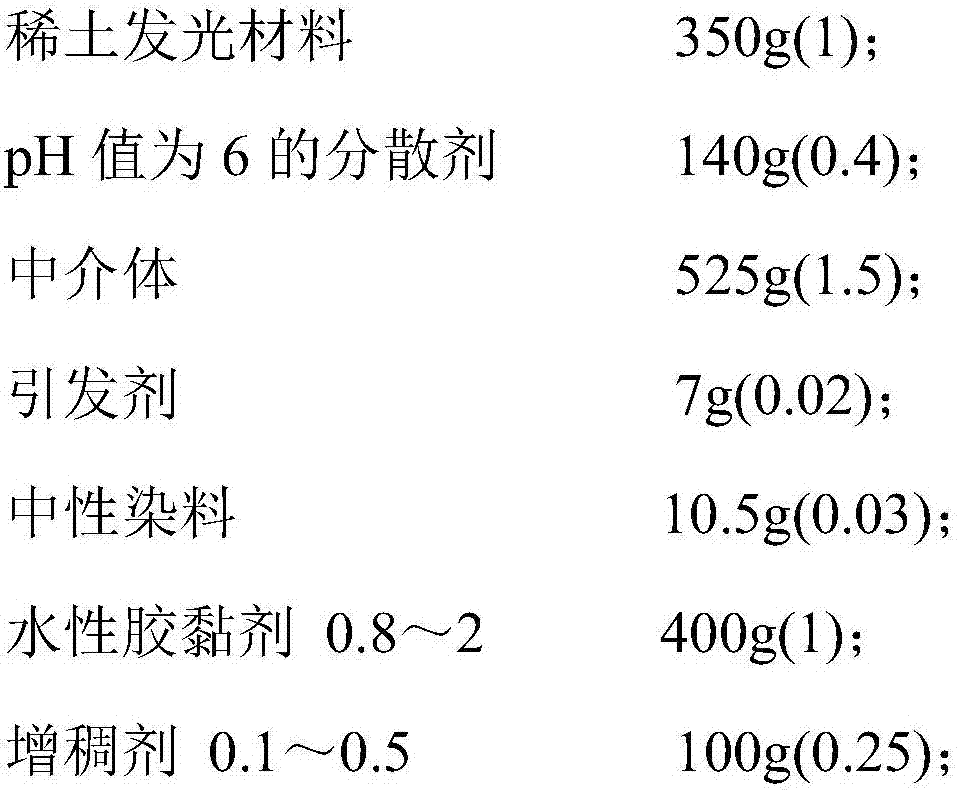

[0045] A luminous printing paste, comprising the following components:

[0046]

[0047]

[0048] Wherein, the rare earth luminescent material is Eu2O3 rare earth luminescent material. The dispersant is a silicate dispersant. The intermediary is polyurethane polymer. The intermediary in other embodiments may also be an acrylic polymer. The initiator is ammonium persulfate. The dye is an acid complex dye. The water-based adhesive is a polyvinyl alcohol-based water-based adhesive. The thickener is a polyacrylic compound thickener.

[0049] The preparation method of the luminous printing paste of the present invention comprises the following steps:

[0050] a. Add dispersants, intermediaries and dyes to rare earth luminescent materials, and mix them evenly to form a color paste;

[0051] b. Before production on the machine, add water-based adhesive and thickener to the color paste, and stir evenly to obtain the luminous printing color paste, so that the luminous printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com