Ultrashort-cavity multi-wavelength single-frequency laser based on doping of different rare earth nanoparticles

A nanoparticle and ultra-short cavity technology, applied in the field of ultra-short cavity multi-wavelength single-frequency lasers, can solve the problems of complex laser structure, small interval between two wavelengths, and low output efficiency, and achieve strong selectivity, compact structure, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

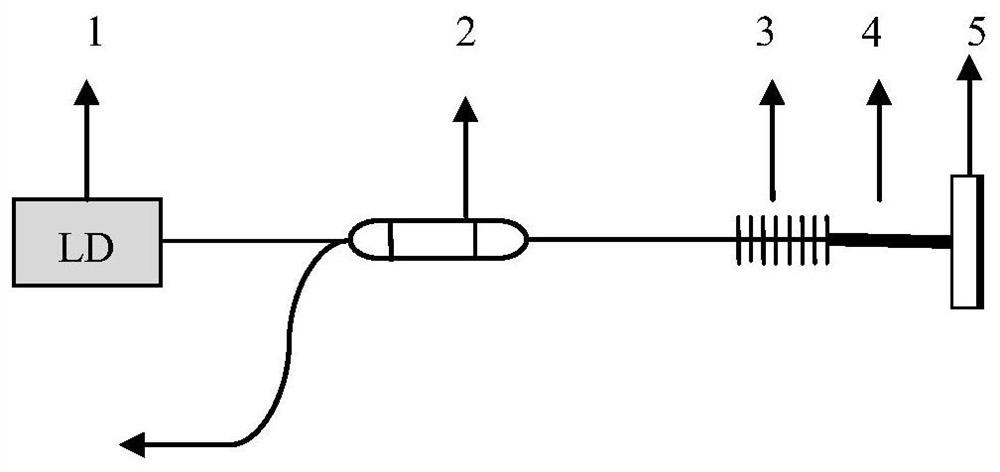

[0022] Example 1 The structure of the ultra-short cavity dual-wavelength single-frequency laser based on the doping of different rare earth nanoparticles provided in this example is as follows: figure 1 As shown, it includes a 976 nm pump source 1, a fiber wavelength division multiplexer 2, a Bragg grating group 3, a gain fiber 4 and a high-reflection mirror 5, which are arranged in sequence along the optical path.

[0023] Among them, the pump source 1 is used to transmit the pump laser, the Bragg grating group 3 and the high reflection mirror form an ultra-short linear laser resonator, and a temperature control system is arranged outside the resonator to adjust and maintain the temperature of the laser resonator. The fiber wave The demultiplexer 2 connects the pump source 1 and the resonator, and injects the 976 nm pump laser emitted from the pump source into the resonator.

[0024] The pump source 1 described in this embodiment is a continuous pump source, and the center wa...

Embodiment 2

[0030] Example 2 The structure of the ultra-short cavity dual-wavelength single-frequency laser based on the doping of different rare earth nanoparticles provided in this example is as follows: figure 1 As shown, it includes a 976 nm pump source 1, a fiber wavelength division multiplexer 2, a Bragg grating group 3, a gain fiber 4 and a high-reflection mirror 5, which are arranged in sequence along the optical path.

[0031] Among them, the pump source 1 is used to transmit the pump laser, the Bragg grating group 3 and the high reflection mirror form an ultra-short linear laser resonator, and a temperature control system is arranged outside the resonator to adjust and maintain the temperature of the laser resonator. The fiber wave The demultiplexer 2 connects the pump source 1 and the resonator, and injects the 976 nm pump laser emitted from the pump source into the resonator.

[0032] The pump source 1 described in this embodiment is a pulsed pump source, and the center wavele...

Embodiment 3

[0038] Embodiment 3 The structure of the ultrashort cavity three-wavelength single-frequency laser based on different rare earth nanoparticles doping provided in this embodiment is as follows: figure 1 As shown, it includes a 976 nm pump source 1, a fiber wavelength division multiplexer 2, a Bragg grating group 3, a gain fiber 4 and a high-reflection mirror 5, which are arranged in sequence along the optical path.

[0039] Among them, the pump source 1 is used to transmit the pump laser, the Bragg grating group 3 and the high-reflection mirror form an ultra-short linear laser resonator, and a temperature control system is arranged outside the resonator to adjust and maintain the temperature of the laser resonator. The fiber wave The demultiplexer 2 connects the pump source 1 and the resonator, and injects the 976 nm pump laser emitted from the pump source into the resonator.

[0040] The pump source 1 described in this embodiment is a pulsed pump source, and the center wavelen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gate length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com