Polycarboxylic acid superplasticizer based on lignin based polyether monomer as well as preparation method thereof and application thereof to concrete

A technology of lignin polyether and polyether polycarboxylate, applied in the field of concrete superplasticizer, can solve the problem that polycarboxylate superplasticizer and conventional superplasticizer cannot be used in combination, unclear, lost, and the content of unsaturated double bonds Low problems, to achieve the effect of strong controllability of molecular structure, obvious viscosity reduction and high dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

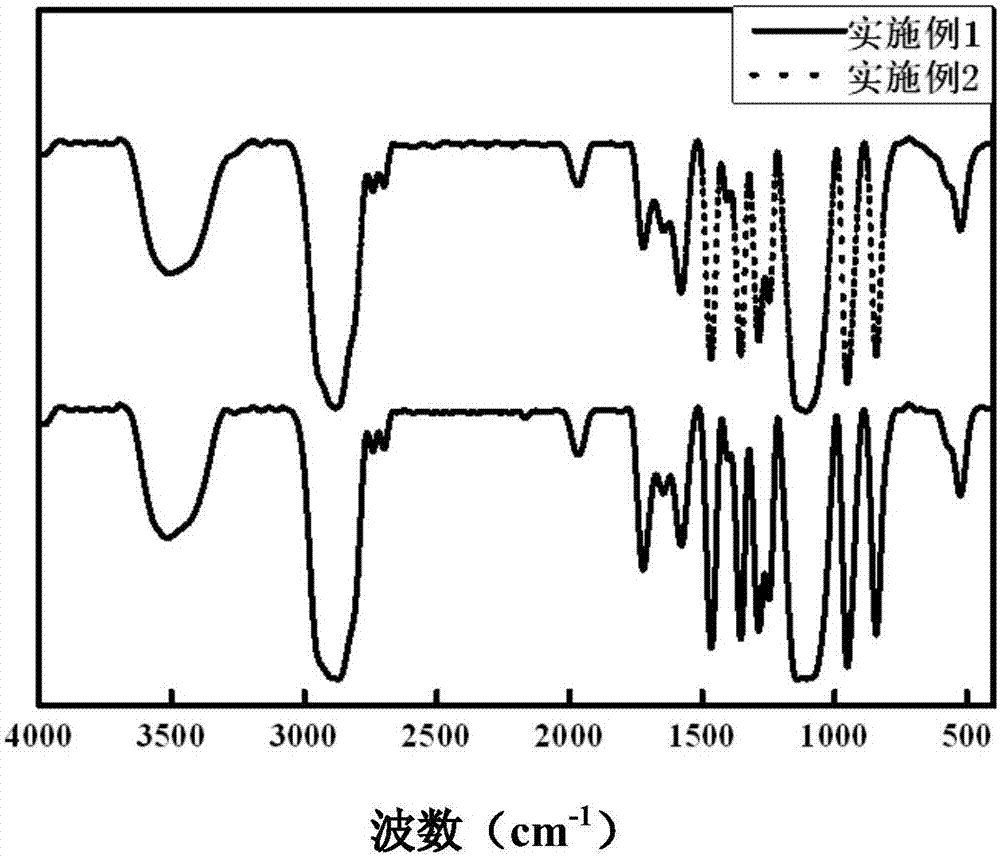

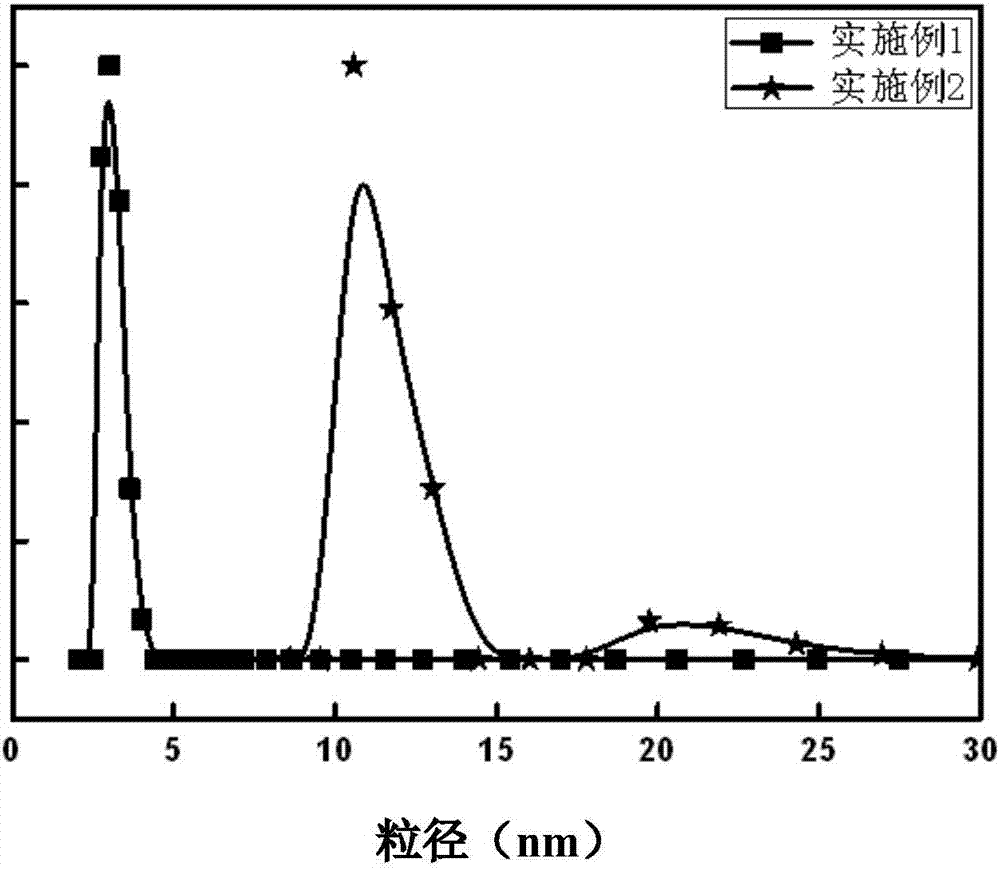

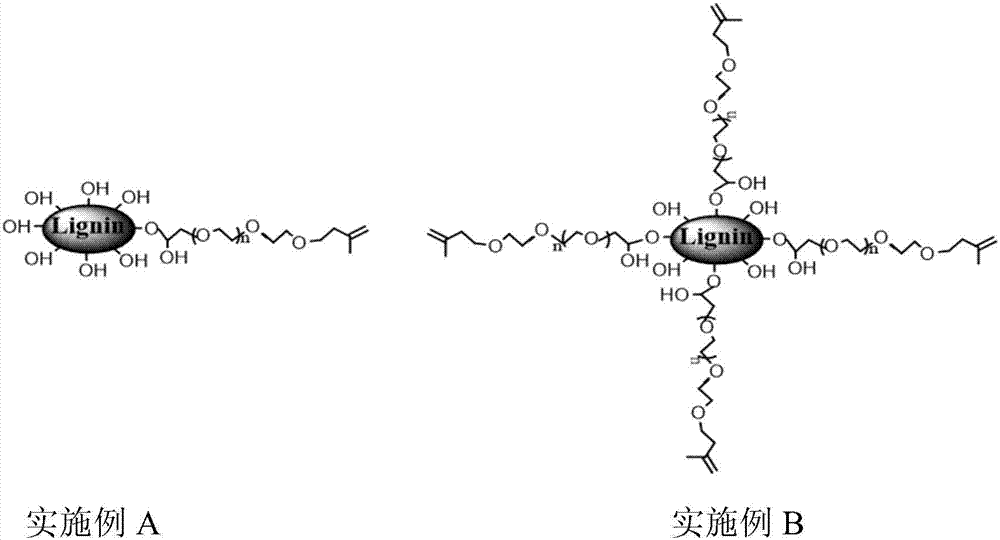

[0055] Embodiment A: Preparation of lignin polyether

[0056] Mix 120g of wheatgrass alkali lignin, 15g of NaOH, and 300g of water, stir mechanically to dissolve all the lignin, and then leave it for 4 to 8 hours until the bubbles disappear to obtain a lignin solution. Heat 100g of unsaturated polyether with a relative molecular weight of 2400 to 60°C to melt it completely, add 0.5g of boron trifluoride-ether solution and 4.5g of epoxychloroethylene dropwise, react for 2 hours, and dissolve the lignin lye Add all of it, raise the temperature to 90°C, and react for 2.5 hours to obtain lignin polyether.

Embodiment B

[0057] Embodiment B: Preparation of lignin polyether

[0058] Take 30g of wheatgrass alkali lignin, 5g of NaOH, and 192g of water, mix them, mechanically stir to dissolve all the lignin, and then leave it for 4 to 8 hours until the bubbles disappear to obtain a lignin solution. Heat 100g of unsaturated polyether with a relative molecular weight of 2400 to 60°C to melt it completely, add 0.5g of boron trifluoride-ether solution and 4.5g of epoxychloroethylene dropwise, react for 2 hours, and dissolve the lignin lye Add all of it, raise the temperature to 90°C, and react for 2.5 hours to obtain lignin polyether.

Embodiment 1

[0059] Embodiment 1: Preparation of lignin polyether polycarboxylate water reducer

[0060] 99g of polyalkoxyalkenyl long-chain unsaturated monomer (TPEG2400), 1.5g of ammonium persulfate and 1g of lignin polyether prepared in Example A were dissolved in 100g of water to obtain a polyether mixed solution; 12.9g of acrylic acid was dissolved in Prepare solution A in 50g of water; dissolve 0.35g of ascorbic acid and 0.5g of mercaptoethanol in 40g of water to prepare solution B;

[0061] Stir the polyether mixture evenly, and raise the temperature to 65°C, then add 2g of ammonium persulfate into the reaction flask at one time, keep stirring mechanically, then add solution A and solution B dropwise respectively, solution A is added dropwise for 3 hours, solution B Add dropwise for 3.5 hours, continue to keep warm for 1.5 hours after solution B is added dropwise, stop the reaction, and when the reaction solution cools down to room temperature, adjust the pH of the reaction solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com