Method for preparing ultrafine copper powder by secondary atmosphere reduction

A technology of ultra-fine copper powder and secondary atmosphere, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor particle dispersion and sintering, and achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

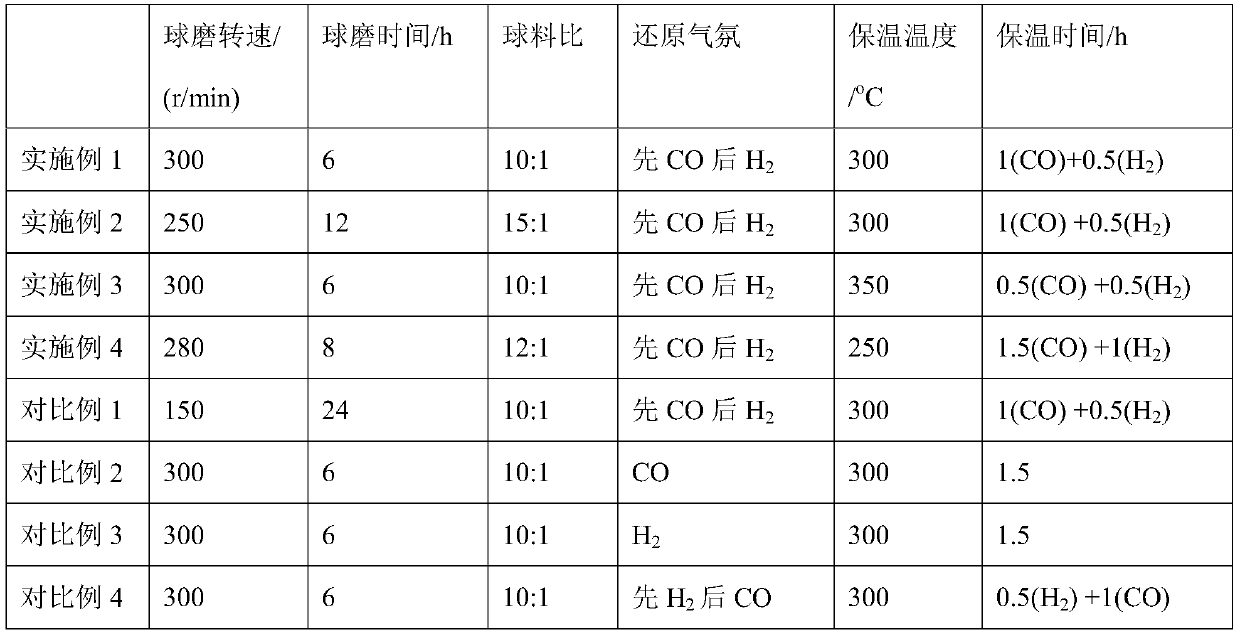

[0057] 1) The cuprous oxide powder and the process control agent (PCA) stearic acid are mixed by simple mechanical stirring. The amount of stearic acid added is 0.5% of the copper oxide powder mass;

[0058] 2) After weighing the above mixed powder, weigh the zirconia balls according to the ball-to-material ratio of 10:1, put them together into a ball mill jar, vacuumize to 15Pa, and then pass in a protective atmosphere of argon .

[0059] 3) Put the ball mill pot into a planetary ball mill for ball milling, the ball milling speed is 300r / min, and the ball milling time is 6h.

[0060] 4) Spread the ball-milled powder into the corundum boat, control the thickness within 2mm, then slowly put the corundum boat into the tube furnace, vacuumize until the ambient pressure in the tube does not exceed 15Pa; then fill it with nitrogen or inert gas to 1 atmosphere.

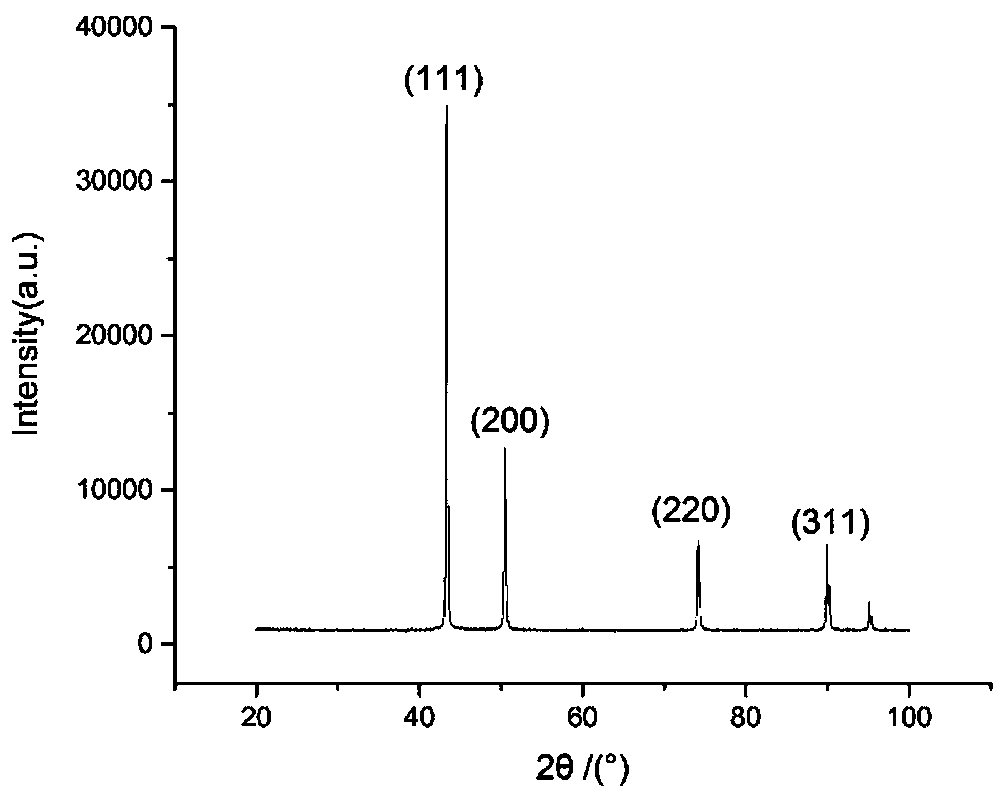

[0061] 5) When the temperature is raised to the holding temperature of 300°C at a heating rate of 6°C / min, a CO atmosp...

Embodiment 2

[0065] The preparation method is basically the same as in Example 1, except that the amount of stearic acid added is 2% of the mass of copper oxide powder, the ball milling speed is 250r / min, the ball milling time is 12h, and the ball-to-material ratio is 15:1. The heating rate was 4°C / min.

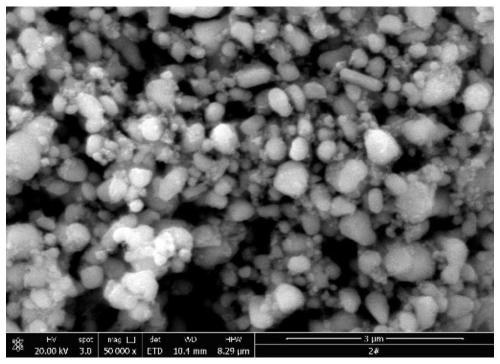

[0066] After reduction, the oxygen content is 0.08wt%, the powder shape is approximately spherical, there is no obvious sintering phenomenon between the particles, the particle size is 0.500-1 μm copper powder particles, and the color of the copper powder is rose red.

Embodiment 3

[0068] The preparation method is basically the same as in Example 1, except that the amount of stearic acid added is 1.2% of the mass of the copper oxide powder, the ball milling speed is 300r / min, the ball milling time is 6h, and the heating rate is 5°C / min. The reduction temperature is 350°C, and the holding time for the first stage of CO reduction is 0.5h.

[0069] After reduction, copper powder particles with an oxygen content of 0.05wt%, approximately spherical powder appearance and a particle size of 0.3-0.8 μm are obtained, but there is no obvious sintering phenomenon between the particles, and the color of the copper powder is rose red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com