Epoxidized soybean oil flexibilizer as well as preparation method and application thereof

A technology of epoxidized soybean oil and toughening agent, which is applied in the direction of organic chemistry, can solve the problem of epoxidized soybean oil losing light stabilization, and achieve good thermal stability and migration resistance, high reactivity, and good toughening effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step a, 156g2,2,6,6-tetramethylpiperidinamine and 76g thiourea are added to a three-necked flask with a stirring device, a thermometer and a spherical condenser with an outlet pipe, and the oil bath is heated to make the thiourea Dissolve completely, continue to heat up to 150°C, keep stirring for 6h, and cool to room temperature.

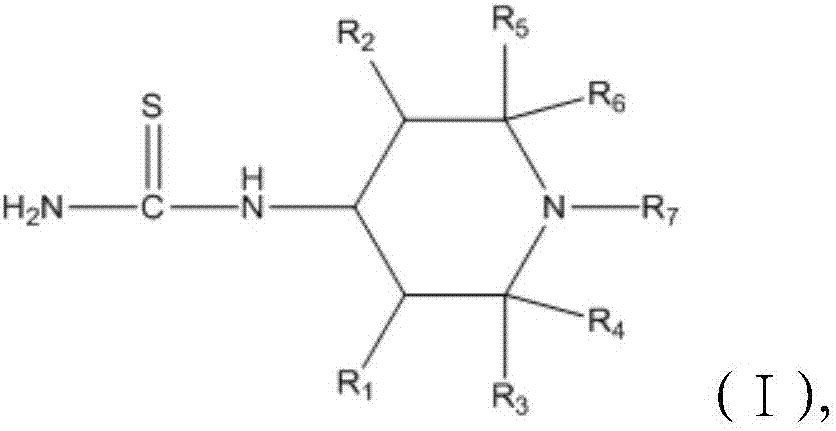

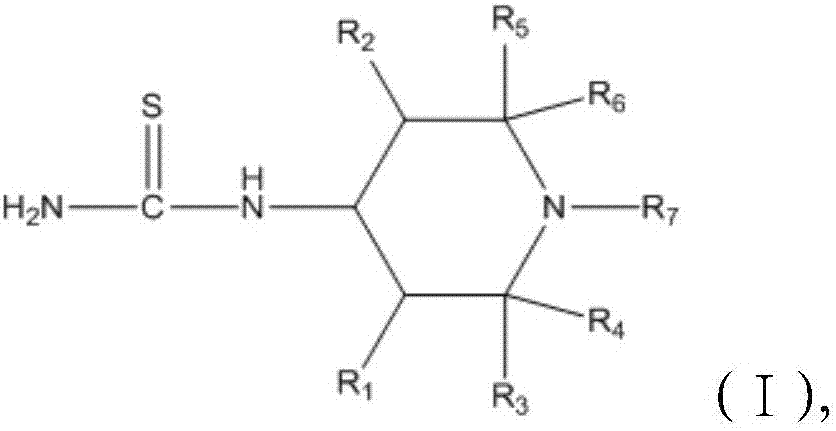

[0052] Tested by GC-MS, the molecular weight of the obtained compound is 215. According to the carbon nuclear magnetic resonance spectrum structure confirmation, the chemical shift of the N-H proton on the piperidine ring appears at δ1.91ppm, and the chemical shift of the N-H proton connected to the C=S bond on the piperidine ring The shift occurs at δ8.90ppm, NH linked to C=S bond 2 The chemical shift of the proton appears at δ8.56ppm, and the ratio of the three peak areas is 1:1:2, all of which prove the occurrence of condensation reaction. The structural formula of the piperidine amine compound of the thiourea modification that makes is ...

Embodiment 2

[0055] Step a, 156g2,2,6,6-tetramethylpiperidinamine and 76g thiourea are added to a three-necked flask with a stirring device, a thermometer and a spherical condenser with an outlet pipe, and the oil bath is heated to make the thiourea Dissolve completely, continue to heat up to 200°C, keep stirring for 10h, and cool to room temperature;

[0056] Tested by GC-MS, the molecular weight of the obtained compound is 215. According to the carbon nuclear magnetic resonance spectrum structure confirmation, the chemical shift of the N-H proton on the piperidine ring appears at δ1.91ppm, and the chemical shift of the N-H proton connected to the C=S bond on the piperidine ring The shift appears at δ8.90ppm, the chemical shift of the NH2 proton connected to the C=S bond appears at δ8.56ppm, and the ratio of the three peak areas is 1:1:2, all of which prove the occurrence of condensation reaction. The structural formula of the piperidine amine compound of the thiourea modification that ma...

Embodiment 3

[0059] Step a, 190g 4-amino-1-benzylpiperidine and 76g thiourea are added to a three-necked flask with a stirring device, a thermometer and a spherical condenser with an outlet pipe, heated in an oil bath to completely dissolve the thiourea, continue The temperature was raised to 120°C, kept under stirring for 2h, and cooled to room temperature.

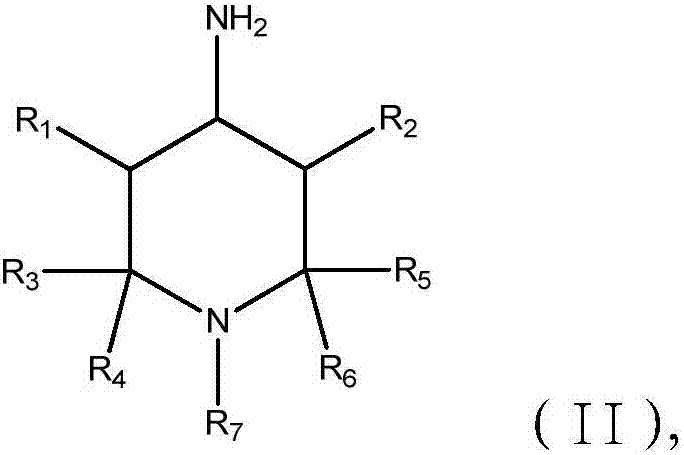

[0060] Tested by GC-MS, the molecular weight of the obtained compound is 249, confirmed by carbon nuclear magnetic resonance spectrum structure, the chemical shift of the N-H proton on the piperidine ring appears at δ1.91ppm, and the NH linked to the C=S bond 2 The chemical shift of the proton appears at δ8.56ppm, and the ratio of the two peak areas is 1:2, all of which prove the occurrence of condensation reaction. The structural formula of the piperidine amine compound of the thiourea modification that makes is shown in formula (I), wherein R 1 , R 2 , R 3 , R 4 , R 5 , R 6 Both are H; R 7 is benzyl.

[0061] Step b, add 95...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com