Cracking furnace with novel furnace tube layout

A cracking furnace and furnace tube technology, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of high temperature, reduce the operation cycle of cracking furnace, and uneven heating of cracking furnace, so as to reduce the difficulty and reduce the occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

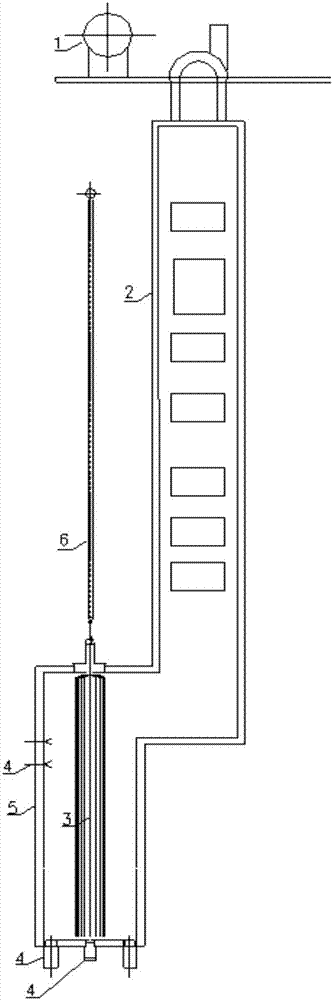

[0046] use figure 1 The cracking furnace shown carries out the cracking reaction. The specific process includes:

[0047] Naphtha at 60°C is gasified and preheated in the convection section 2, and then enters the furnace tube 3 of the radiant section for cracking reaction. The combustion system of the radiant section 5 adopts a combination of a burner at the bottom and a burner at the side wall mode, the heat supply ratio of the burner arranged at the bottom is 80%; the temperature at which naphtha is preheated in the convection section, that is, the crossover temperature (XOT) of the cracking furnace is 590 ° C, and the outlet temperature (COT) of the radiant section of the cracking furnace is 590 ° C. The furnace tube 3 in the radiant section adopts a single-pass furnace tube. The inlet diameter of the furnace tube is 41mm, the outlet diameter of the furnace tube is 53mm, and the length of the furnace tube is 12.8m. The furnace tube adopts bottom-in and top-out. Furnace tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com