Method for selectively separating lithium from positive electrode material of waste lithium-ion battery

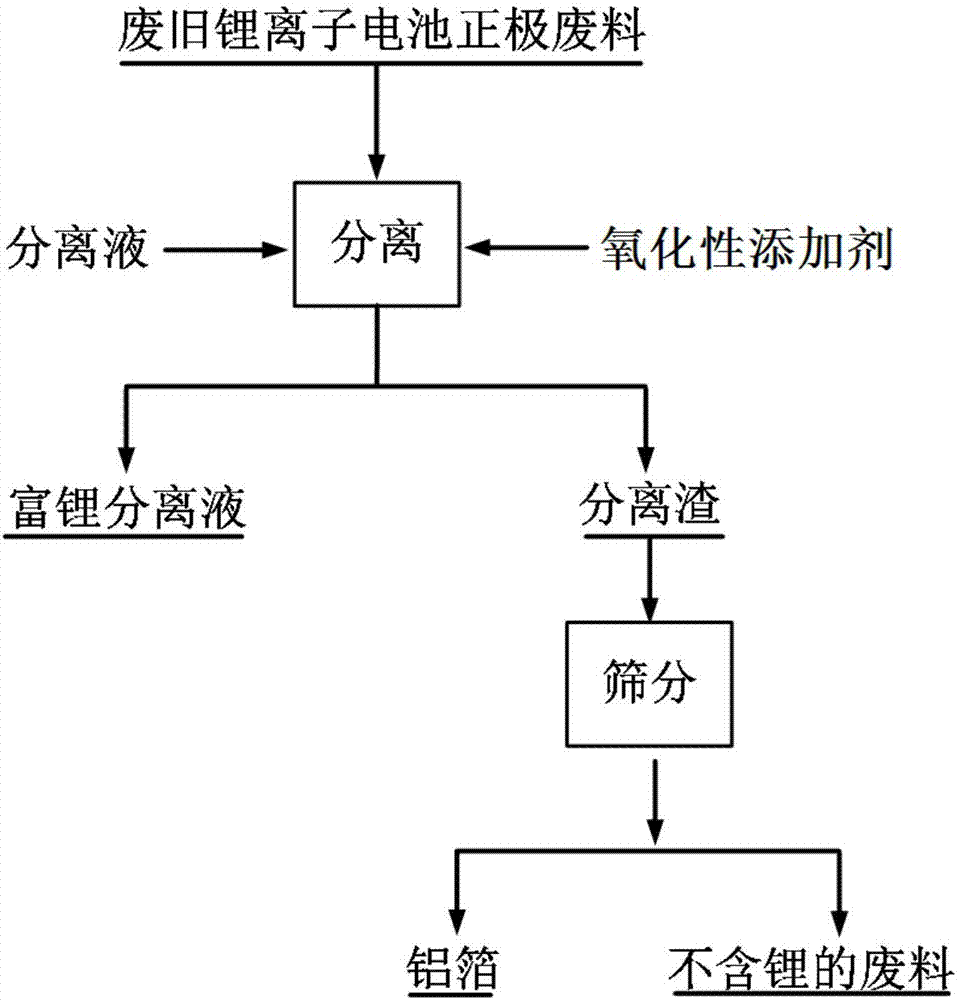

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of selective separation of positive electrode materials of waste lithium ion batteries, can solve the problems of non-selective separation, secondary pollution, long recycling process, etc., and achieves wide application range and no secondary Contamination, the effect of short separation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a method for selectively separating lithium from the positive electrode sheet of a waste lithium-ion battery, and the specific method is as follows:

[0060] (1) Take the lithium cobalt oxide positive electrode sheet waste of lithium ion battery, and measure the mass percentage of metal in the positive electrode waste: Co: 45.28%, Li: 1.13%, Al: 2.06%.

[0061] (2) Take a part of the waste lithium cobaltate positive electrode sheet after step (1) drying, weigh the quality of the positive electrode sheet solid and measure the separation liquid (with a pH value of 4) with the separation liquid at a liquid-solid ratio of 0.6mL / g Acetic acid solution) liquid volume, put into reactor, add oxidizing additive sodium persulfate simultaneously in reaction system (taking the total mass of described separating liquid and oxidizing additive as 100%, the mass percentage composition of oxidizing additive is 3%), carry out reaction, control stirring speed 800r...

Embodiment 2

[0065] This embodiment provides a method for selectively separating lithium from the positive electrode sheet of the waste lithium ion battery. The specific method refers to Example 1, the difference is that the liquid-solid ratio of the positive electrode sheet of the waste lithium cobaltate and the separation liquid is 2mL / g. The results are shown in Table 1.

Embodiment 3

[0067] This embodiment provides a method for selectively separating lithium from the positive electrode sheet of the waste lithium ion battery. The specific method refers to Example 1, the difference is that the liquid-solid ratio of the waste lithium cobaltate positive electrode sheet and the separation liquid is 10mL / g. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com