Cotton seed soaking agent and use method thereof

A cotton seed and seed soaking agent technology, applied in botany equipment and methods, applications, insecticides, etc., can solve problems affecting cotton growth, yield, quality, poor effect, low germination rate, etc., and achieve enhanced resistance to diseases and insect pests Ability, increase germination rate, increase the effect of germination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

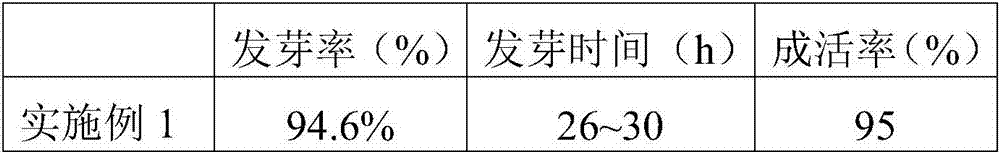

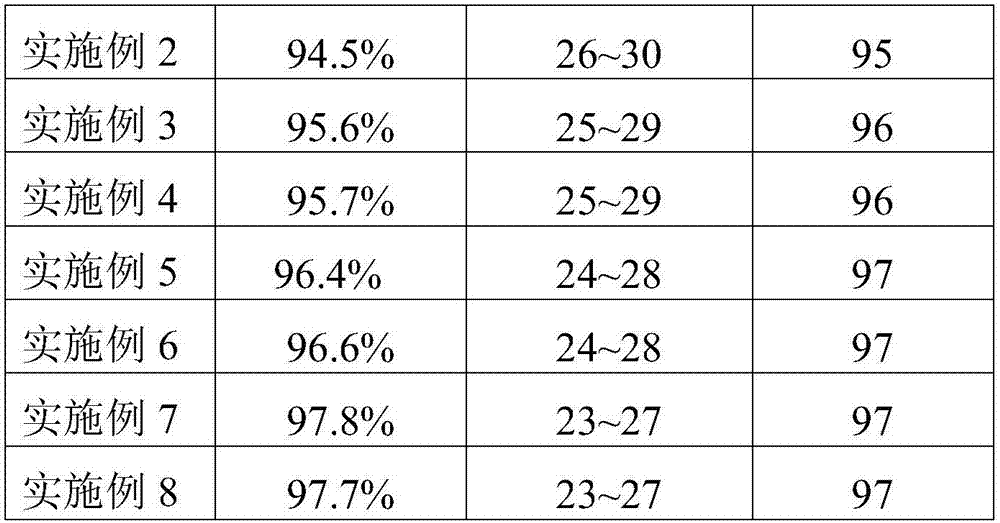

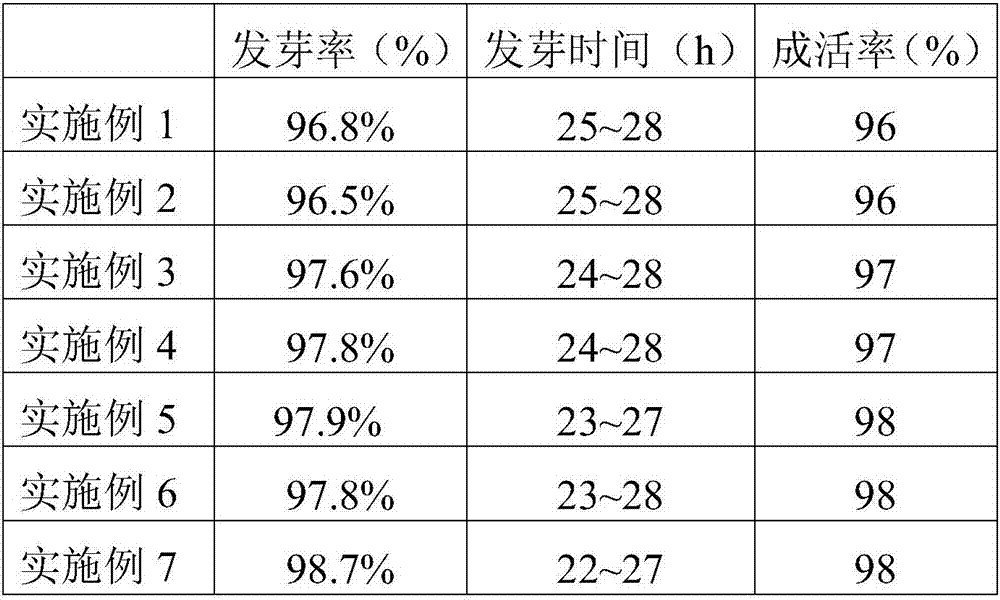

Examples

Embodiment 1

[0024] A kind of cotton seed soaking agent, comprises the raw material of following parts by weight to make:

[0025] 12 parts of benzylamine, 3 parts of paclobutrazol, 0.2 parts of diethyl hexanoate, 0.8 parts of boric acid, 2 parts of sodium lignosulfonate, 3 parts of aspartic acid, 2 parts of water retaining agent, 0.1 part of sodium naphthenate, 0.4 parts of fluorine Sodium silicate, 2 parts of purple sweet potato anthocyanins, 0.6 parts of titanium tetraisopropoxide, 0.2 parts of sodium naphthalene acetate, 0.2 parts of nano zinc oxide, 0.2 parts of vitamin K3, 0.8 parts of dill oil brain, 25 parts of modified wheat rice Stone, 250 copies of rice washing water;

[0026] A kind of preparation method of above-mentioned cotton seed soaking agent, comprises the following steps:

[0027] Step 1. Add mepipepter, paclobutrazol, diethyl hexanoate, sodium naphthalene acetate, vitamin K3, dill oil brain and 1 / 3 part of rice washing water into the container in parts by weight, heat...

Embodiment 2

[0031] A kind of cotton seed soaking agent, comprises the raw material of following parts by weight to make:

[0032]10-15 parts of benzylamine, 2-5 parts of paclobutrazol, 0.1-0.3 parts of diethyl aminoethyl hexanoate, 0.5-1 part of boric acid, 1-3 parts of sodium lignosulfonate, 1-5 parts of aspartic acid, 1-3 parts of water retention agent, 0.1-0.2 part of sodium naphthenate, 0.3-0.5 part of sodium fluorosilicate, 1-2 parts of purple sweet potato anthocyanin, 0.5-0.8 part of titanium tetraisopropoxide, 0.1-0.3 part of sodium naphthalene acetate, 0.1-0.3 parts of nano-zinc oxide, 0.1-0.3 parts of vitamin K3, 0.5-1 part of dill oil brain, 20-30 parts of modified medical stone, 200-300 parts of rice washing water.

[0033] A preparation method of the above-mentioned cotton seed soaking agent, comprising the following steps:

[0034] Step 1. Add benzylamine, paclobutrazol, diethyl diethyl aminoethyl hexanoate, sodium naphthalene acetate, vitamin K3, dill oleoresin and 1 / 3 part...

Embodiment 3

[0038] In the second step, the stirring and mixing process is as follows: add the material and another 2 / 3 part of rice-washing water into the stainless steel spherical container, place the spherical container on the four-axis grinder, turn on the four-axis grinder, and drive the stainless steel spherical container. Random rotation for 60min; the feed port of the stainless steel spherical container is sealed by a screw cap, and the screw cap is flush with the surface of the stainless steel spherical container after being sealed and connected; the rotating shaft speed of the four-axis grinder is 300rpm, and the random transition frequency is 30s ;

[0039] The rest of the process parameters and procedures are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com