a tio 2 -fe 2 o 3 Preparation method and application of composite powder

A technology of composite powder and fe2o3, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve the problems of rough, imperfect and fine morphology of composite materials, and inhibit the photoelectric performance of materials, etc. , to achieve good photocatalytic degradation of dyes and photolysis of water hydrogen production performance, low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

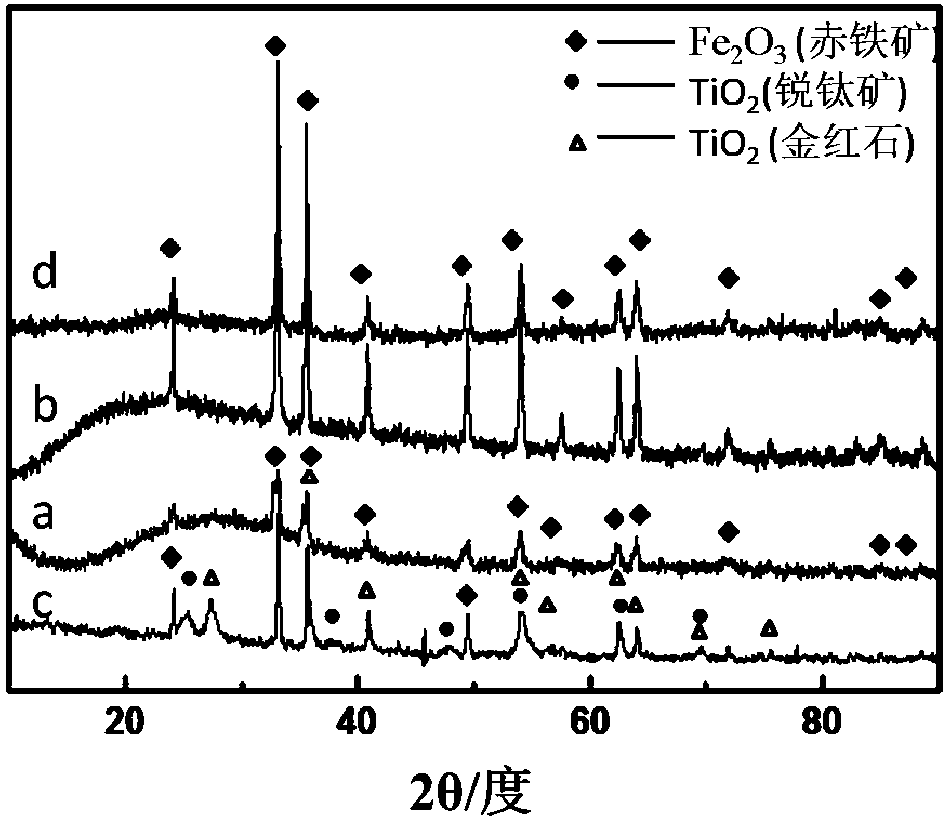

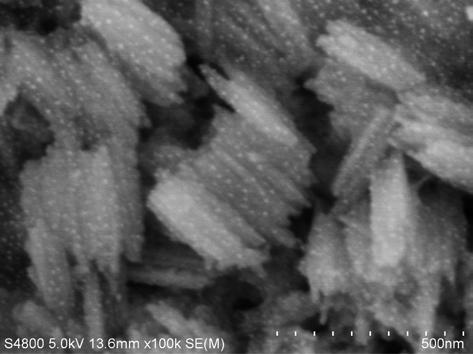

[0032] A kind of TiO 2 / Fe 2 o 3 The preparation method of composite powder, the steps are as follows:

[0033] (1) Extraction of green plant leaf juice: select fresh green leaves and wash them repeatedly with water and ethanol. The green leaves are cut into fine pieces and ground into green leaf juice. Store the extracted green leaf juice in a sterilized centrifuge tube and store it at 4°C, and use it as an organic template and photoreaction carrier in subsequent experiments; in order to maintain the biological activity of the green leaf juice, the extracted green leaf juice must be taken immediately. use.

[0034] (2) TiO 2 / Fe 2 o 3 Preparation of the mixed solution: Weigh 1 g of ferric chloride powder, dissolve it in 20 ml of green leaf juice, stir for 2 h, so that ferric chloride and green leaf juice are fully mixed; according to the volume ratio of green leaf juice and tetrabutyl titanate 20:1 Measure tetrabutyl titanate (that is, the volume of green leaf juice i...

Embodiment 2

[0046] A kind of TiO 2 / Fe 2 o 3 The preparation method of composite powder, the steps are as follows:

[0047] (1) Extraction of green plant leaf juice: select fresh green leaves and wash them repeatedly with water and ethanol. The green leaves are cut into fine pieces and ground into green leaf juice. Store the extracted green leaf juice in a sterilized centrifuge tube and store it at 4°C, and use it as an organic template and photoreaction carrier in subsequent experiments; in order to maintain the biological activity of the green leaf juice, the extracted green leaf juice must be taken immediately. use.

[0048] (2) TiO 2 / Fe 2 o 3 Preparation of mixed solution: Weigh 1.4 g of ferric chloride powder, dissolve it in 20 ml of green leaf juice, stir for 1 hour, so that ferric chloride and green leaf juice are fully mixed; the volume ratio of green leaf juice to tetrabutyl titanate is 10 : 1 Measure tetrabutyl titanate (that is, the volume of green leaf juice is 10 tim...

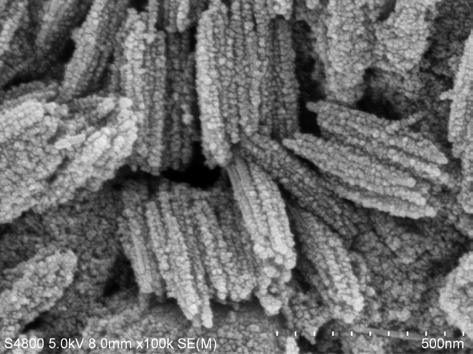

Embodiment 3

[0054] A kind of TiO 2 / Fe 2 o 3 The preparation method of composite powder, the steps are as follows:

[0055] (1) Extraction of green plant leaf juice: select fresh green leaves and wash them repeatedly with water and ethanol. The green leaves are cut into fine pieces and ground into green leaf juice. Store the extracted green leaf juice in a sterilized centrifuge tube and store it at 4°C, and use it as an organic template and photoreaction carrier in subsequent experiments; in order to maintain the biological activity of the green leaf juice, the extracted green leaf juice must be taken immediately. use.

[0056] (2) TiO 2 / Fe 2 o 3 Preparation of the mixed solution: Weigh 3g of ferric chloride powder, dissolve it in 15 ml of green leaf juice, stir for 2 hours, so that ferric chloride and green leaf juice are fully mixed; according to the volume ratio of green leaf juice to tetrabutyl titanate 5: 1 Measure tetrabutyl titanate (that is, the volume of green leaf juice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com