Preparation method of plasma modified hexagonal boron nitride/resin composite material

A technology of hexagonal boron nitride and plasma, which is applied in the field of preparation of plasma modified hexagonal boron nitride/resin high thermal conductivity composite materials, can solve the problem of difficult peeling of layers, difficult surface modification and poor performance of composite materials And other problems, to achieve the effect of improving the connection, low cost, and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Modified boron nitride / epoxy resin thermally conductive composite material.

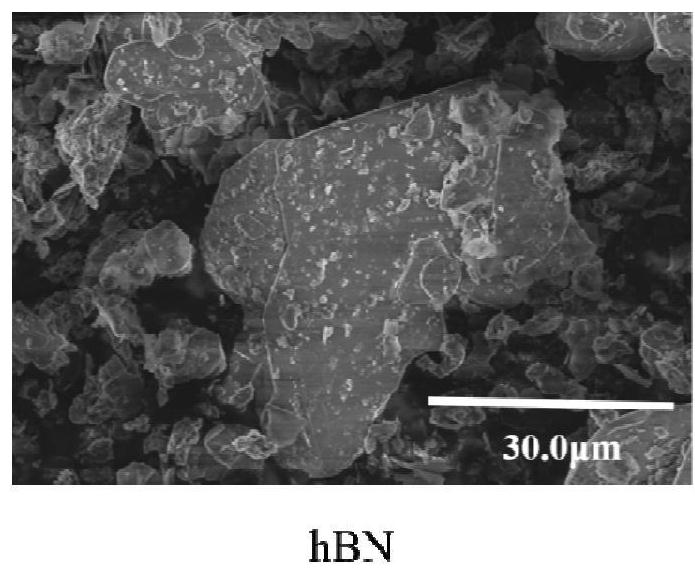

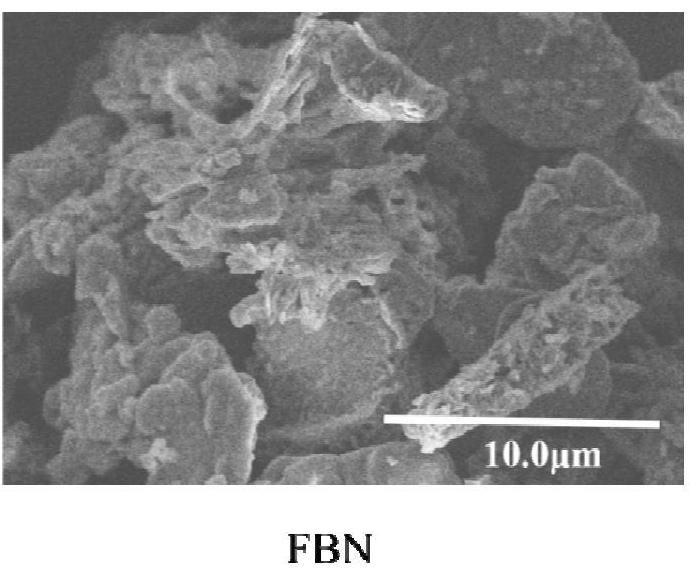

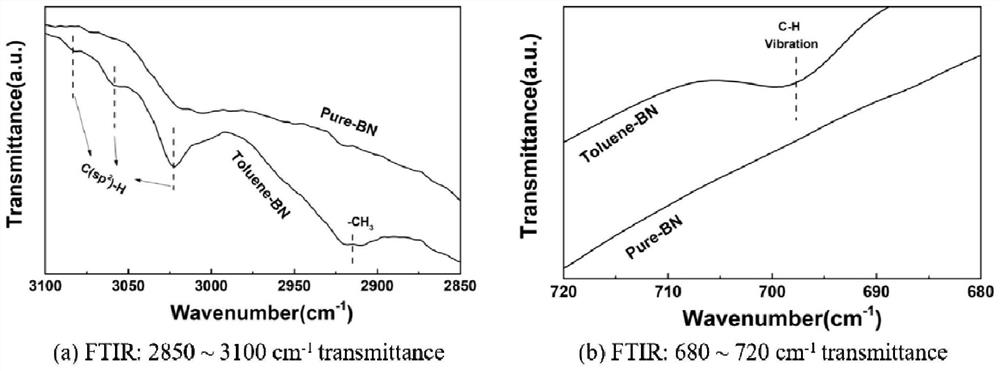

[0021] Step 1, place the boron nitride powder in the quartz tube, pass in an inert gas of 9.6sccmAr, control the pressure inside the quartz tube to 280Pa, turn on the radio frequency source (set power 300W) to generate plasma, and heat the toluene at the bottom of the quartz tube. Free radicals deposit on the surface of boron nitride and form a coating film to prepare modified boron nitride (FBN).

[0022] Step 2, mix EP and curing agent T-31, heat and stir until the resin is completely dissolved, then add the above-mentioned FBN powder to it, and continue to maintain the temperature and stir. The temperature of heating and stirring was 40°C.

[0023] Step 3: Pre-cure the FBN resin mixture at 80°C for 30 minutes, then perform hot pressing at 220MPa and 80°C, and finally take out the pressed sheet and perform the final heat curing at 120°C for 1 hour to obtain a composite materia...

Embodiment 2

[0024] Example 2: Modified boron nitride / polyvinyl alcohol thermally conductive composite material.

[0025] Step 1, place the boron nitride powder in the quartz tube, pass in an inert gas of 9.6sccmAr, control the pressure inside the quartz tube to 280Pa, turn on the radio frequency source (set power 300W) to generate plasma, and heat the deionized water at the bottom of the quartz tube. Free radicals are grafted on the surface of boron nitride to prepare modified boron nitride (FBN).

[0026] Step 2: Mix the modified boron nitride powder with polyvinyl alcohol solution (mass fraction: 25wt%), then place the mixture in an oven, dry it at 80°C for 90 minutes, and take it out for hot pressing at 220MPa and 80°C.

[0027] Step 3, finally take out the pressed tablet (mass fraction 87.60wt%), use the German NETZSCH LFA467 thermal conductivity meter to measure the thermal diffusivity of the composite material, and its in-plane thermal diffusivity is 7.606 mm 2 / s, the vertical the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com