A co-doped tio 2 Process for photocatalyst degradation of wastewater

A photocatalyst and co-doping technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, water/sewage treatment, etc., can solve the unsystematic research and doping of degradation processes Modification and other issues, to achieve the effect of improving visible light catalytic efficiency, mild preparation conditions, and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

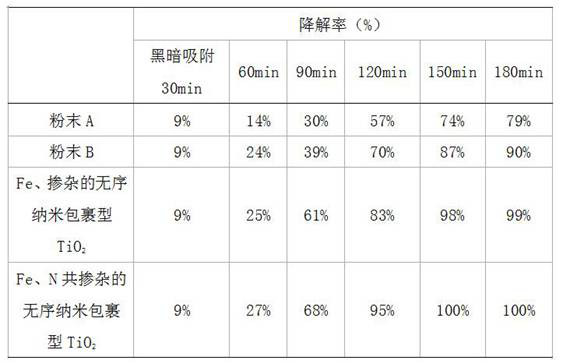

Image

Examples

Embodiment 1

[0035] 1. Disordered nano-encapsulated TiO 2 Preparation of:

[0036] a. TiO 2 and NaBH 4 Mix and grind for 0.5h to obtain a mixture, the TiO 2 with NaBH 4 The mass ratio is 1:0.65;

[0037] b. Transfer the mixture obtained in step a into an alumina crucible, then place it in a tube furnace, raise the temperature from room temperature to 350°C at a rate of 10°C / min under a nitrogen atmosphere, and maintain it under this condition for 0.5h, and then Furnace is cooled to room temperature, obtains the powder after reaction;

[0038] c. Transfer the powder obtained in step b into an alumina crucible, then place it in a tube furnace, raise the temperature from room temperature to 400°C at a rate of 10°C / min under an argon atmosphere, and maintain it under this condition for 0.5h, then Cool to room temperature with the furnace, and wash with ethanol and water several times and dry to obtain the powder A after reaction;

[0039] d, the powder A obtained in step c is mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com