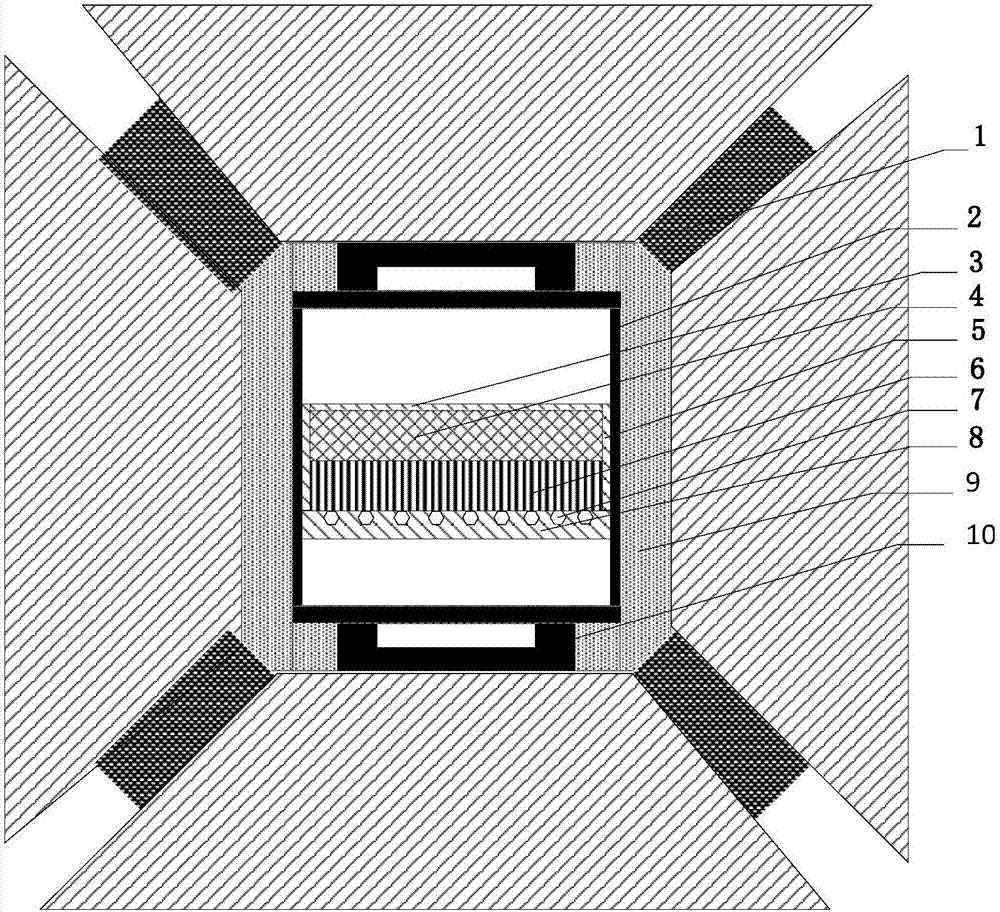

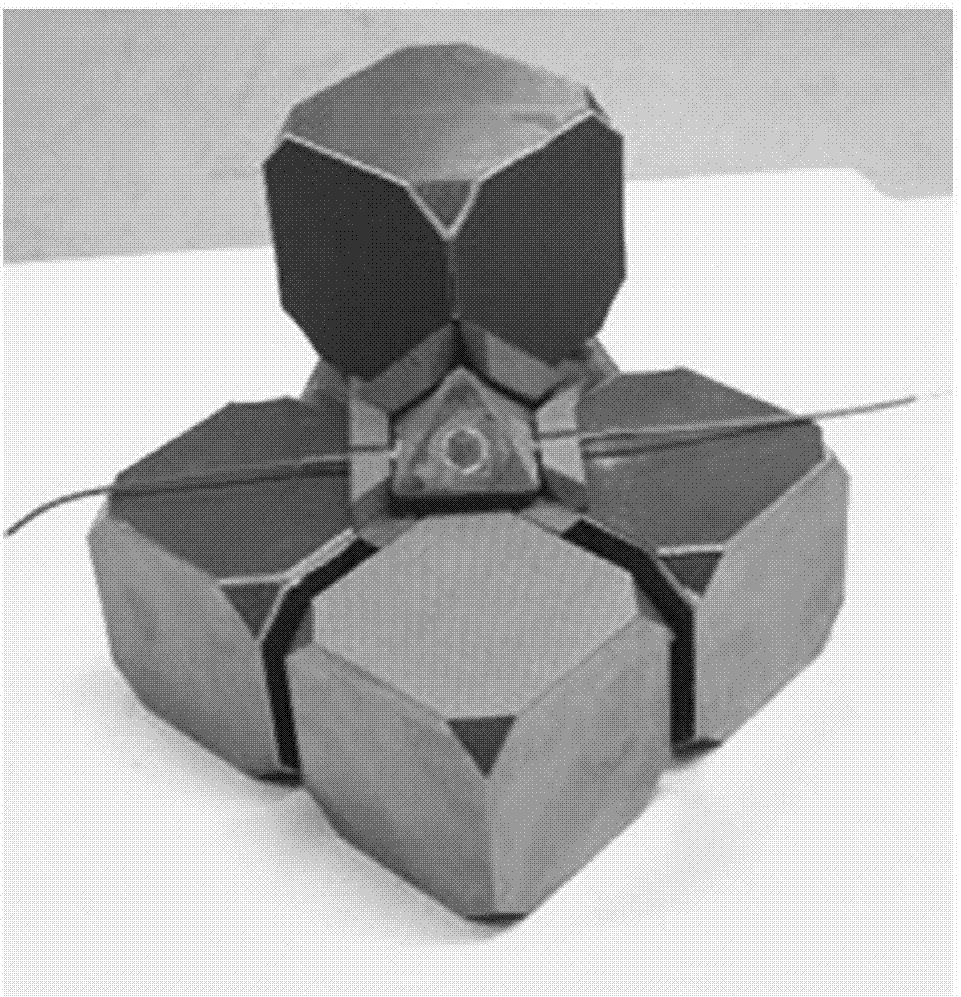

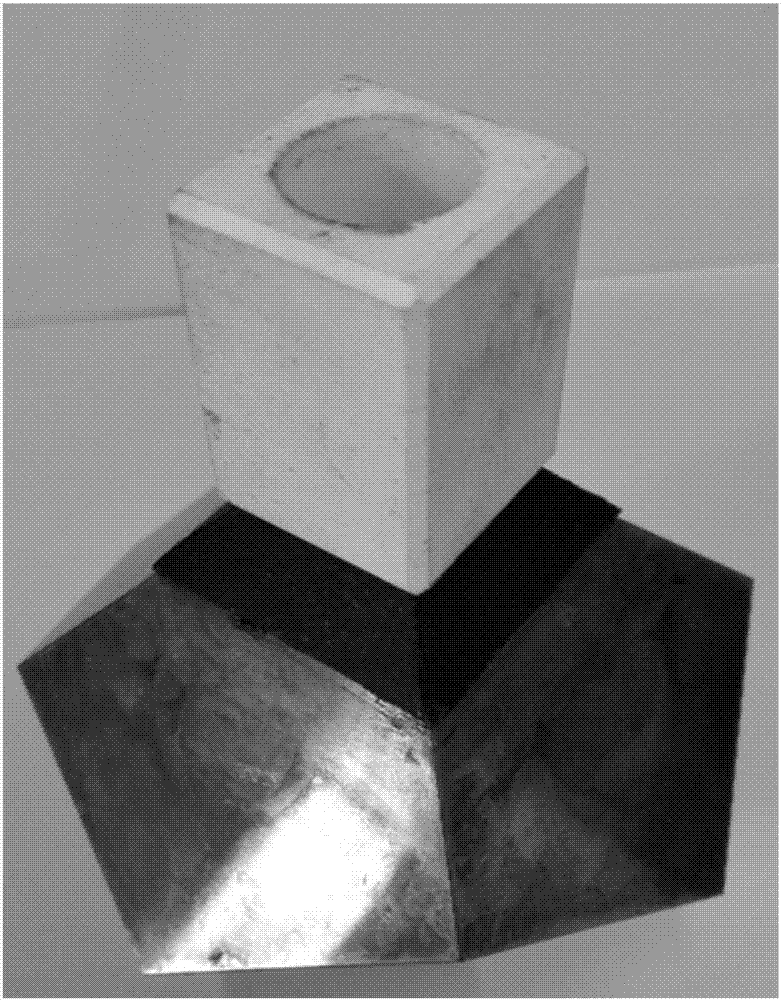

Composite sealing ring for ultrahigh-pressure synthetic artificial diamond device and preparation method

A technology of artificial diamond and composite sealing ring, which is applied in the field of materials, can solve the problems that cannot be implemented on a large scale, it is difficult to control the repeatability, etc., and achieve the effect of reducing the broken rate and sufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of the composite sealing ring that is used for no press machine sub-ball type ultra-high pressure synthesis device (BARS), described method comprises the steps:

[0035] S1: Raw material selection and proportioning, specifically, the composition and proportioning of raw materials used in the composite sealing ring are as follows: select paddock red natural pyrophyllite blocks, crush and sieve to remove +100 micron powder particles, 800°C Roasting 1 hour; Then the obtained high-temperature baking pyrophyllite powder, silica pyroxene fiber powder, commercially available metal surface thermal spraying epoxy resin powder are taken by mass ratio 85%: 10%: 5%, and the total mass is 1000 grams; Chopped silica pyroxene micro-powder has an aspect ratio of 7:1-10:1 and a diameter of 10-20 microns. The epoxy resin is commercially available E12 epoxy resin powder with a particle size (D50) of 80 mesh.

[0036] S2: Ingredients and mixing, specifically, w...

Embodiment 2

[0042] A kind of preparation method of the composite sealing ring that is used for no press machine sub-ball type ultra-high pressure synthesis device (BARS), described method comprises the steps:

[0043] S1: Selection and proportioning of raw materials, specifically, the composition and proportioning of raw materials used in the composite sealing ring are as follows: select paddock red natural pyrophyllite blocks, crush and sieve to remove +100 micron and -18 micron powder Particles were roasted at 800°C for 1 hour; then the obtained high-temperature baked pyrophyllite powder, silicon pyroxene fiber powder, and commercially available epoxy resin powder for thermal spraying on metal surfaces were weighed in a mass ratio of 80%:15%:5%. , the total mass is 1000 grams; the aspect ratio of silica pyroxene fiber powder is 5:1-7:1, and the diameter is 10-20 microns. The epoxy resin powder adopts commercially available E12 epoxy resin powder, and the particle size (D50) is 300 head;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com