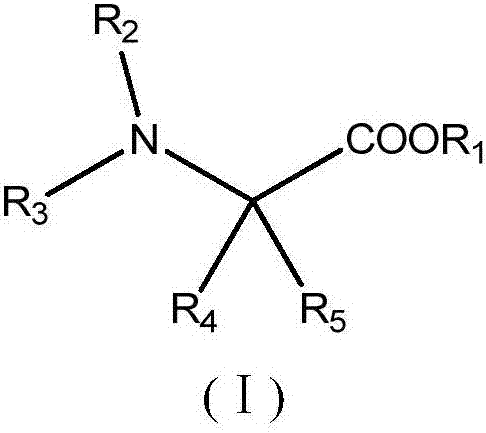

Catalyst component for olefin polymerization as well as preparation method and application of catalyst component

An olefin polymerization and catalyst technology, applied in the application and field of olefin polymerization reaction, can solve the problems of large titanium tetrachloride, the comprehensive performance of catalyst needs to be further improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

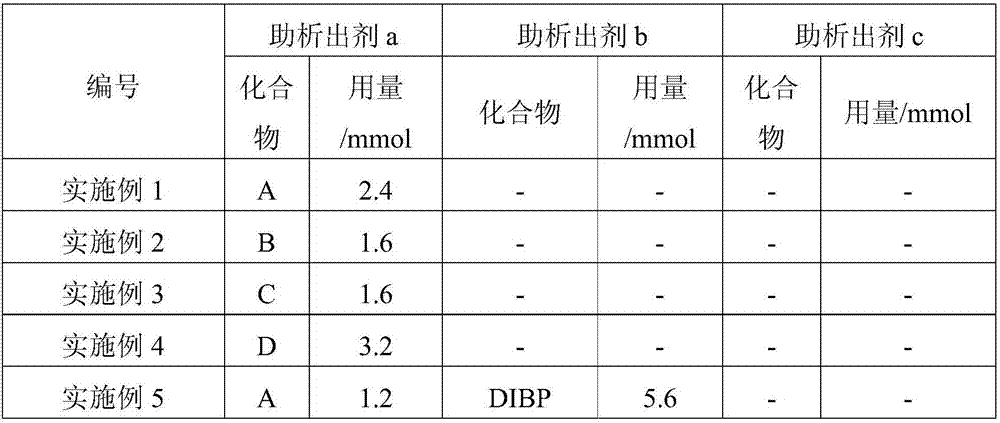

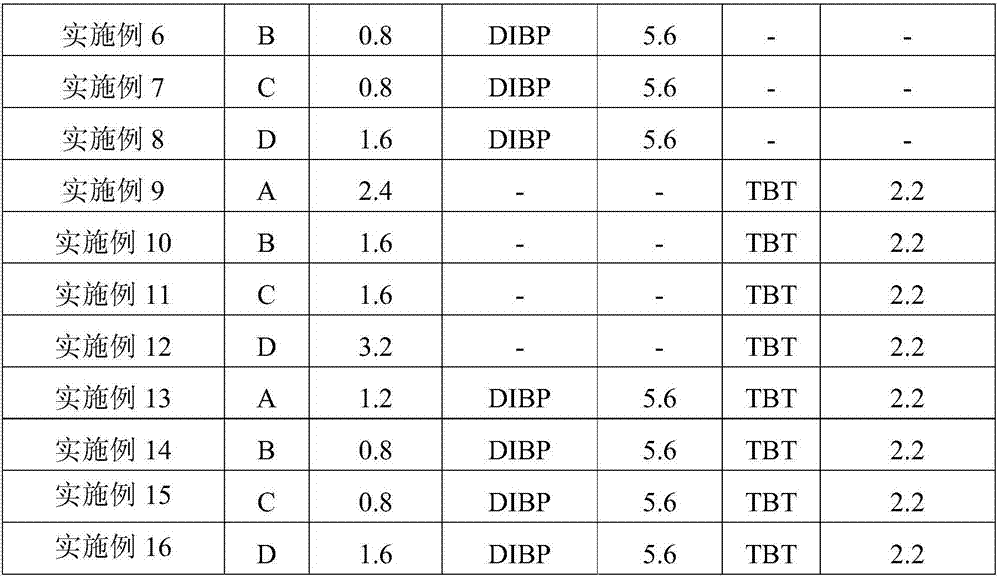

Examples

preparation example Construction

[0078] The preparation method of catalyst component for olefin polymerization provided by the invention comprises the steps:

[0079] (1) In the presence of a hydrocarbon solvent, contact anhydrous magnesium chloride and an alcohol compound at a temperature of 30-150°C for 0.5-10h, preferably at a temperature of 60-140°C for 0.5-6h, to obtain a uniform Alcoholate solution; wherein, the molar ratio of anhydrous magnesium chloride to alcohol compounds is 1:2-4, preferably 1:2.5-3.5;

[0080] (2) Add the eluting agent to the above alcoholate solution, wherein the molar ratio of anhydrous magnesium chloride to the eluting agent is 1:(0.01-0.9), preferably 1:(0.01-0.33), more preferably 1 :(0.03-0.20);

[0081] Add the above-mentioned alcoholate solution with precipitation aid to the mixture of titanium compound and inert diluent at -40°C to 0°C, and make them contact and react at a temperature of -40°C to 0°C by stirring 3- 5 hours, then raise the temperature to 50-150°C, prefer...

preparation example 1

[0094] Preparation of amino ester compound A (N, N-di-n-butylaminoacetate):

[0095] Add di-n-butylamine (77.4g, 0.6mol) in 1000mL there-necked flask, K 2 CO 3 (82.8g, 60mmol), KI (1.8g, 12mmol), acetonitrile (400mL), was added dropwise with ethyl bromoacetate (85.8g, 0.51mmol), and refluxed for 8 hours; after the reaction was completed, the cooling system was filtered to remove salt, Wash the solid with 2×100mL dichloromethane, wash the organic phase with 2×100mL saturated brine, dry the organic phase with anhydrous sodium sulfate, filter, distill off the solvent under reduced pressure, and rectify to obtain the product (5mmHg, 64°C).

[0096] Carry out NMR determination to product, test method and result are: 1 HNMR (CDCl 3 / TMS,300MHz)δ(ppm):0.67-0.88(t,6H,-NCH 2 CH 2 CH 2 CH 3 ),1.05-1.17(q,4H,-NCH 2 CH 2 CH 2 CH 3 ),1.20-1.29 (tetra,3H,-COOCH 2 CH 3 ), 1.20-1.49 (m,4H,-NCH 2 CH 2 CH 2 CH 3 ),2.30-2.70(m,4H,-NCH 2 CH2 CH 2 CH 3 ),3.30(s,2H,-NCH 2 COOEt...

preparation example 2

[0098] Preparation of amino ester compound B (N, N-di-n-octylaminoacetate)

[0099] The method is the same as that in Preparation Example 1, except that di-n-butylamine is replaced by di-n-octylamine to prepare N,N-di-n-octylaminoacetate ethyl ester.

[0100] Carry out NMR determination to product, test method and result are: 1 H NMR (CDCl 3 / TMS,300MHz)0.86-0.93(m,6H,-NC 7 h 14 CH 3 ),1.27(tetra,3H,-COOCH 2 CH 3 ), 1.27(m,20H,-NCH 2 CH 2 C 5 h 10 CH 3 ),1.49(m,4H,-NCH 2 CH 2 C 5 h 10 CH 3 ), 2.30-2.60 (m,4H,-NCH 2 C 7 h 15 ),3.30(s,2H,-NCH 2 COOEt), 4.13 (tetra,2H,-COOCH 2 CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com