Preparation method of quick-response glucose-sensitive hydrogel

A hydrogel and glucose technology, applied in the field of biomedical polymer materials, can solve the problems of long response time and weak intensity of external stimuli, achieve the effect of enhancing glucose sensitivity and responsiveness, and improving the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

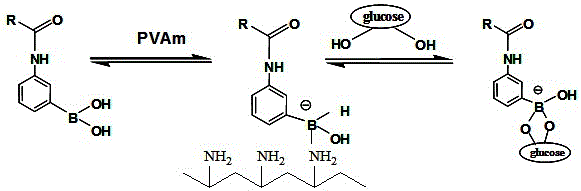

Method used

Image

Examples

Embodiment 1

[0045] Weigh 0.0960gAAPBA, 0.1560gAM and 0.0156gMBA respectively, add to 1ml 1% chitosan (CS) solution to dissolve. Pipette 1.2ml of DMAEMA and 10μl of TEMED, and mix well. Then add 0.5ml of ammonium persulfate solution APS (40mg / ml) into the solution, after mixing, quickly pipette 1ml of the solution and add it to the reactor, react for about 1h, and pass N through the whole process 2 protection, and finally a film-like gel is obtained. Put the prepared gel film in distilled water at constant temperature for 48 hours, replace the distilled water every 6 hours, then put the gel film in the buffer solution for 48 hours, replace the solution every 6 hours, and dry the purified gel spare.

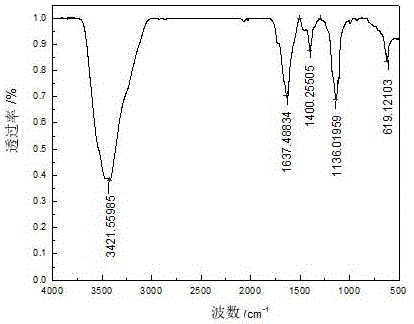

[0046] Figure 4 is the infrared spectrum of the synthesized CS / P (AAPBA-DMAEMA-AM) hydrogel.

[0047] Polymer at 3436.98cm -1 The absorption peak is the overlapping peak of -NH and -OH stretching vibration peaks, 1740.01cm -1 and 1637.48cm -1 The absorption peaks at are the characteris...

Embodiment 2

[0049] Weigh 0.0960gAAPBA, 0.310gAM and 0.0156gMBA, respectively, and add them into 1ml of 2% polyvinylpyrrolidone (PVP) solution to dissolve. Pipette 0.6ml of DMAA and 10μl of TEMED, and mix well. Then add 0.5ml of ammonium persulfate solution APS (40mg / ml) into the solution, after mixing, quickly pipette 1ml of the solution and add it to the reactor, react for about 1h, and pass N through the whole process 2 Protect, and finally get a film-like gel Put the prepared gel film in distilled water at constant temperature for 48 hours, replace the distilled water every 6 hours, then put the gel film in the buffer solution for 48 hours, replace the solution every 6 hours , and dry the purified gel for later use.

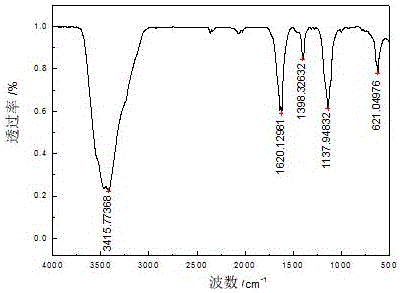

[0050] The infrared spectrum of PVP / P(AAPBA-DMAA-AM) is as follows Figure 5 . The absorption peaks at 3444cm-1 and 1643cm-1 are the stretching vibration absorption peaks of NH and C=O, respectively, indicating that the polymer contains amido and amidophenylboronic aci...

Embodiment 3

[0052] Weigh 0.1920gAAPBA, 0.638gAM and 0.0156gMBA, respectively, and add them into 1ml of 2% PVP solution to dissolve. Pipette 10 μl of TEMED and mix well. Then add 0.5ml of ammonium persulfate solution APS (40mg / ml) into the solution, after mixing, quickly pipette 1ml of the solution and add it to the reactor, react for about 1h, and pass N through the whole process 2 protection, and finally a film-like gel is obtained. Put the prepared gel film in distilled water at constant temperature for 48 hours, replace the distilled water every 6 hours, then put the gel film in the buffer solution for 48 hours, replace the solution every 6 hours, and dry the purified gel spare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com