Trench-gate superjunction device and manufacturing method thereof

A technology of super junction devices and manufacturing methods, which is applied in the field of trench gate super junction devices and trench gate super junction devices, and can solve the problems of application system current and voltage overshoot, circuit failure, circuit damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

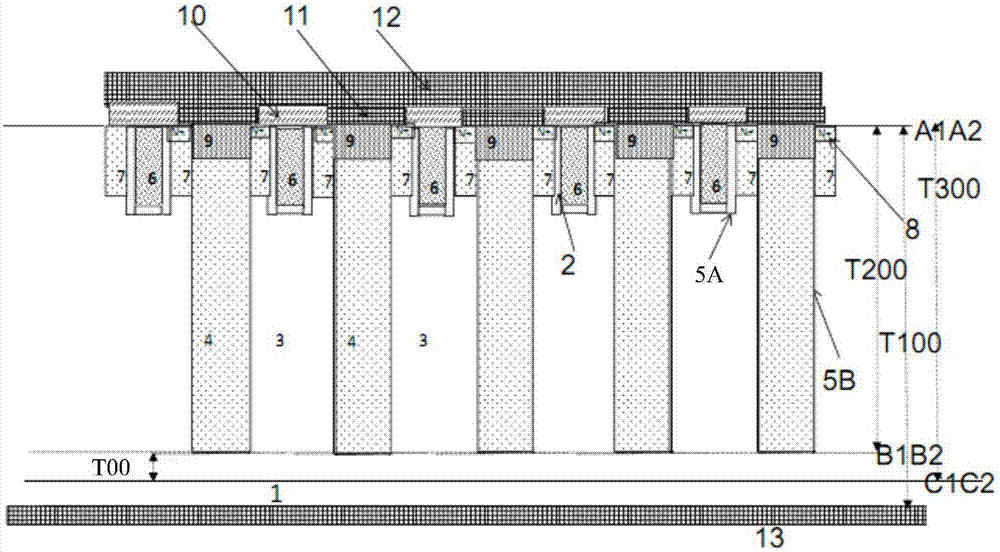

[0116] Embodiment of the present invention a trench gate super junction device:

[0117] Such as Figure 4 Shown is a schematic top view of a superjunction device according to an embodiment of the present invention; Figure 5A is along Figure 4 Schematic cross-sectional view of the centerline C2; Figure 5B is along Figure 4 Schematic cross-sectional view of the center line C3; Figure 5C is along Figure 4 Schematic cross-sectional view of the center line C4; Figure 5D is along Figure 4 Schematic cross-sectional view of the center line C1;

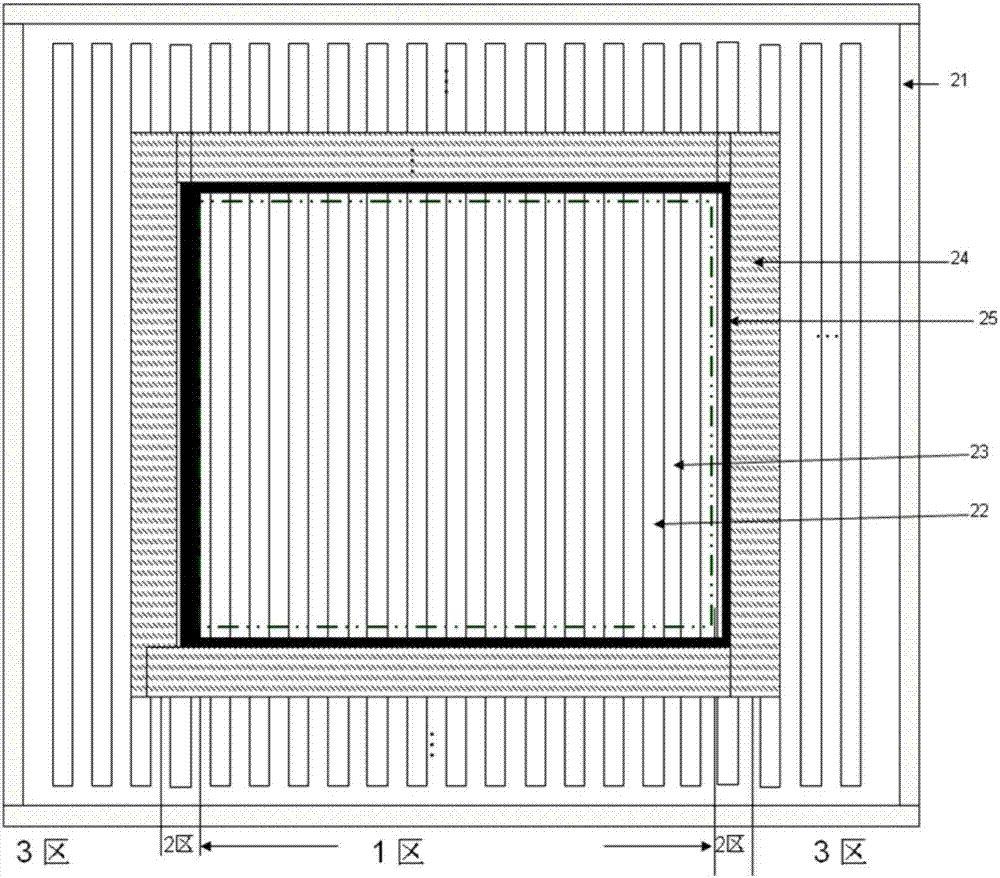

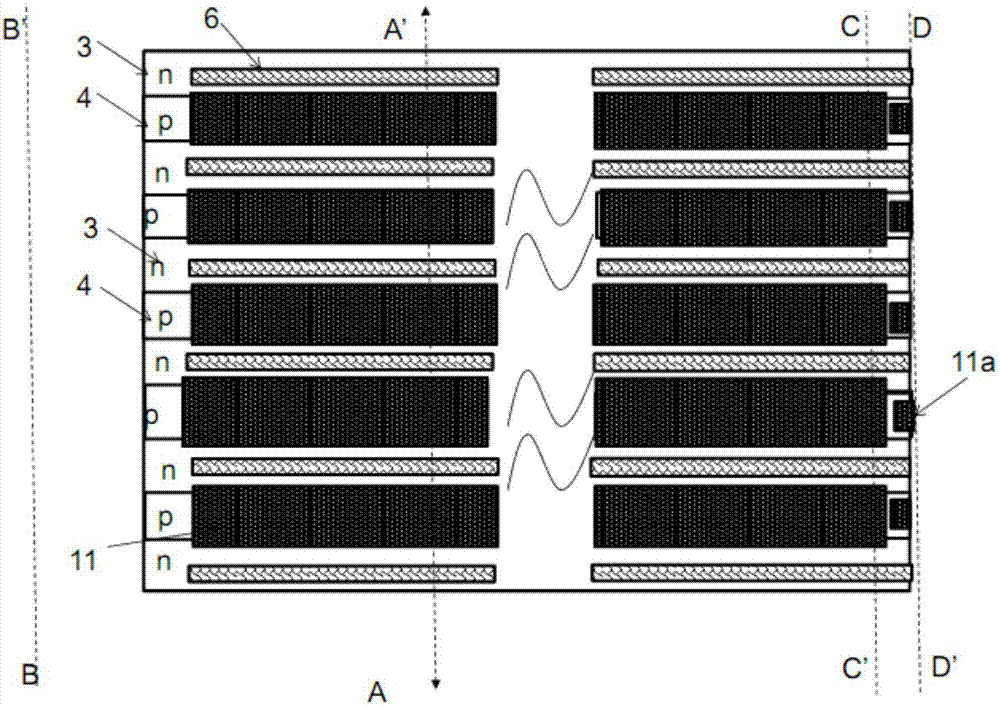

[0118] Embodiment 1 of the present invention, a superjunction device includes a charge flow region, a termination region laterally subjected to a reverse bias voltage, and a transition region between the charge flow region and the termination region, and the termination region surrounds the periphery of the charge flow region, including For the structure of the entire charge flow region, transition region and terminal region, pl...

Embodiment 2

[0144] Embodiment 2 of the present invention Trench gate super junction device:

[0145] Such as Image 6 As shown, it is a schematic top view of a trench gate super junction device in Embodiment 2 of the present invention; the difference between the trench gate super junction device in Embodiment 2 of the present invention and the trench gate super junction device in Embodiment 1 of the present invention is that the present invention Embodiment 2 In the trench-gate superjunction device: a contact region 9 composed of a P+ region is formed on the top of each floating P-type column 4a extending into the transition region, and a contact region 9 is formed on the top of the contact region 9 and connected to The contact hole 11b to said source, ie the contact hole marked with the reference 11b alone. After the contact hole 11b is formed, the two ends of the floating P-type column 4a will be connected to the source, but the middle area located in the charge flow region will not be...

Embodiment 3

[0146] Three-trench gate super-junction device according to the embodiment of the present invention:

[0147] Such as Figure 7 As shown, it is a schematic top view of the three-trench gate super-junction device of the embodiment of the present invention; the difference between the three-trench gate super-junction device of the embodiment of the present invention and the first trench gate super-junction device of the present invention is that the present invention In the trench gate super junction device of the third embodiment: a P-type ring 7a is formed on the surface of the super junction structure in the transition region, and a contact region 9 composed of a P+ region is formed on the top of the P-type ring 7a and formed A contact hole 11c on top of the contact region 9 and connected to the source. The doping concentration of the P-type ring 7a is the same as that of the P-type well 7; or, the doping concentration of the P-type ring 7a is different from that of the P-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com