Solar cell and manufacturing method thereof

A technology for a solar cell and a manufacturing method, applied in the field of solar cells, can solve the problems of inability to meet requirements, inability to achieve high-efficiency performance, and high probability of defective products, and achieve the effects of improving conversion efficiency, increasing internal electron mobility, and realizing frequent changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

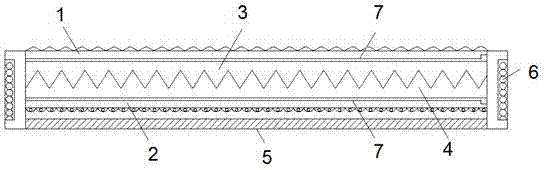

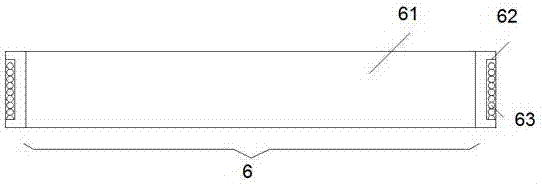

[0031] see Figure 1-3 , the present invention provides a technical solution: a solar cell, comprising an upper plate 1 and a lower plate 2, a phosphorus-doped layer 3 is formed on the bottom surface of the upper plate 1, and a phosphorus-doped layer 3 is formed on the upper surface of the lower plate 2. There is a boron-doped layer 4, and the phosphorus-doped layer 3 and the boron-doped layer 4 are bonded together, and the bottom surface of the lower plate 2 is bonded with a reflective refractor 5 with a changing reflection angle, and the upper plate 1 and the lower plate The outer wall of the pole plate 2 is sleeved with a magnetic field conversion device 6 to increase the ion exchange speed, the upper pole plate 1 and the lower pole plate 2 are silicon plates, and the bottom surface of the upper pole plate 1 and the upper surface of the lower pole plate 2 are embedded There are electrodes 7 .

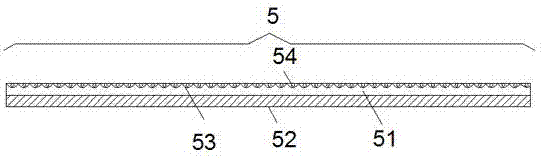

[0032] The reflective refraction plate 5 includes a bottom plate 51, the bottom...

Embodiment 2

[0041] A method for manufacturing a solar cell is provided:

[0042] The first step is silicon wafer cutting, material preparation, solar-grade monocrystalline or polycrystalline silicon rods made by the crucible Czochralski method, the original shape is cylindrical, and then cut into square silicon wafers (or polycrystalline square silicon wafers), silicon wafers The side length is generally 10~15cm, the thickness is about 200~350um, and the resistivity is about 1Ω.cm;

[0043] In the second step, texturing, the surface of the relatively smooth raw silicon wafer is etched by acid or alkali to make it uneven and rough, forming diffuse reflection and reducing the loss of solar energy directly hitting the surface of the silicon wafer. For monocrystalline silicon, the method of adding NaOH and alcohol is generally used for etching. Using the anisotropic etching of monocrystalline silicon, countless pyramid structures are formed on the surface. The temperature of the lye is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com