Hard alloy disc pin cutter and production process thereof

A cemented carbide and production process technology, applied in the field of cemented carbide disc foot cutter and its production process, can solve the problems of easy fracture and low bending strength, achieve good compactness, improve compactness and optimize process effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

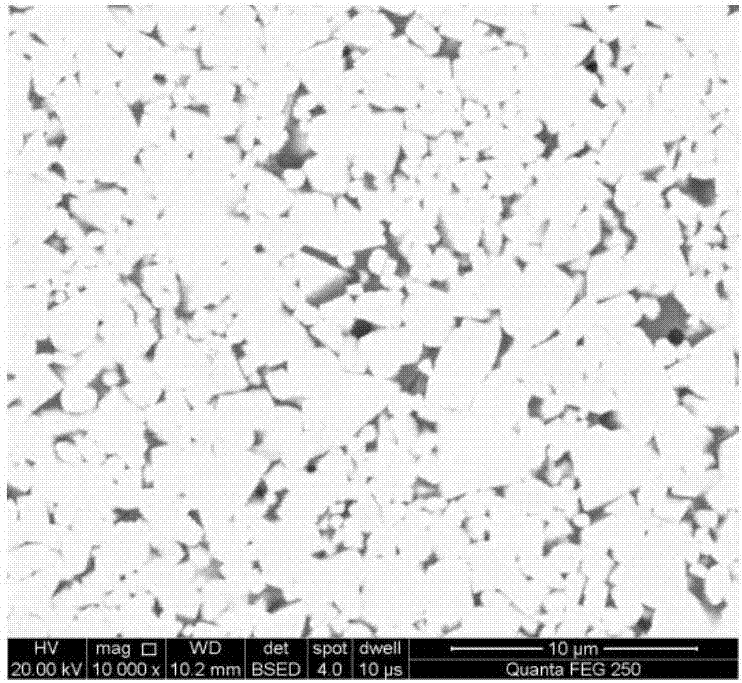

Embodiment 1

[0063] The present embodiment provides a kind of production technology of cemented carbide disc cutting foot knife, comprises the following steps:

[0064] S1. 0.5% ZrO2, 0.1% La by weight percentage 2 o 3 , 6% Co powder, 0.03% Y 2 o 3 , 93.37% WC powder is mixed to obtain 1Kg of mixture, the WC powder in the mixture has a Fischer particle size of 2um, and the Co powder has a Fischer particle size of 1.5um. Add 1Kg of the mixture into a ball mill cylinder with a volume of 2L, and add cemented carbide grinding rods 3Kg, the wet grinding medium is industrial alcohol with a water content of 5wt%, the wet grinding time is 30h, and the slurry is obtained after wet grinding; the slurry is dried for 5-7h, and the dried material powder is mixed with glue and granulated, and then pressed into The disc knife is degummed and sintered, the final sintering temperature is 1450°C, and the heat preservation is 1h, and the disc knife blank is made;

[0065] S2. The processing and molding i...

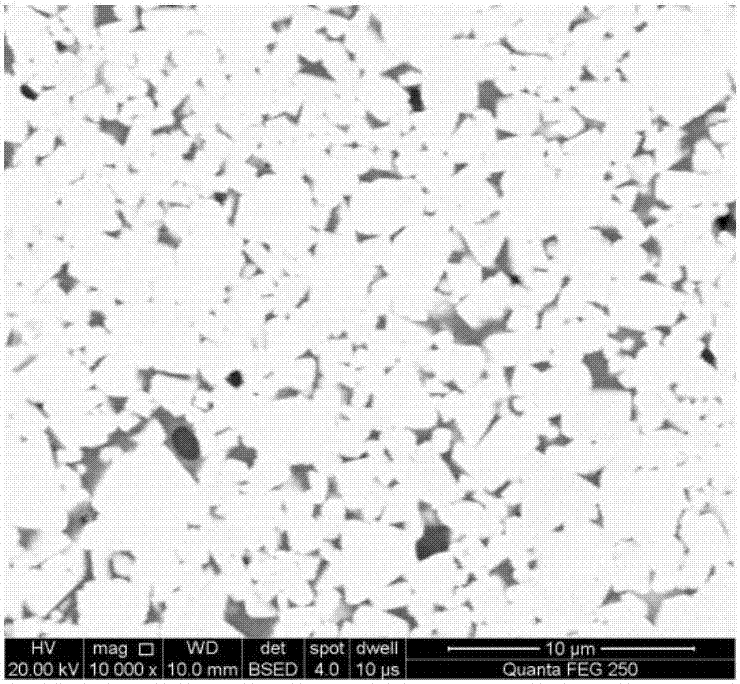

Embodiment 2

[0075] A kind of production technology of hard alloy disc cutting foot knife of present embodiment, comprises the following steps:

[0076] S1. 0.3% ZrO2, 0.3% La by weight percentage 2 o 3 , 6% Co powder, 0.01% Y 2 o 3 , 93.39% WC powder mixed to obtain 1Kg mixture, the WC powder Fisherman's particle size in the mixture is 2um, the Co powder Fisherman's particle size is 1.5um, put 1Kg of the mixture into a ball mill cylinder with a volume of 2L, and add cemented carbide grinding rods 3Kg, the wet grinding medium is industrial alcohol with a water content of 5wt%, the wet grinding time is 30h, and the slurry is obtained after wet grinding. The slurry is dried for 5-7h, and the dried material powder is mixed with glue and granulated, and then pressed Form a disc cutter, carry out degumming and sintering, the final sintering temperature is 1450°C, keep warm for 1h, and make a disc cutter blank;

[0077] S2. The processing and molding in this embodiment is mainly aimed at the...

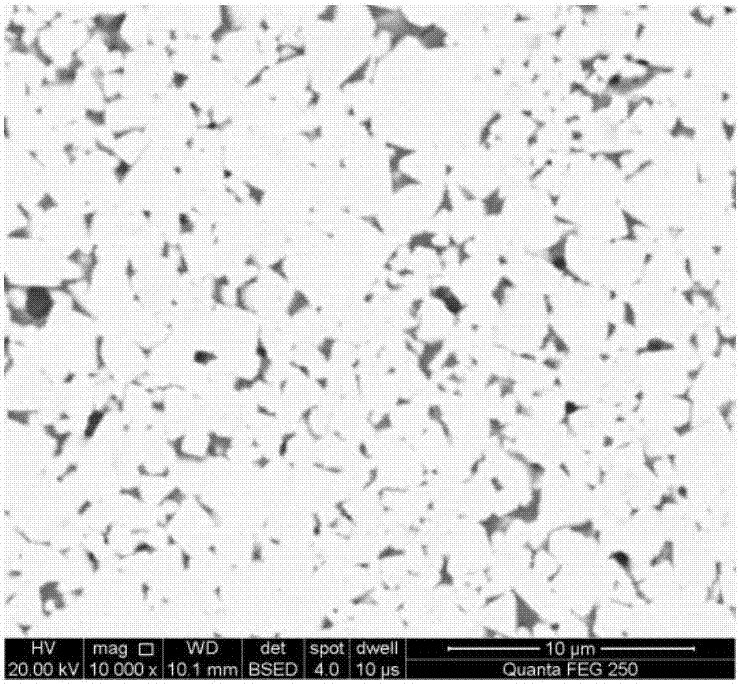

Embodiment 3

[0087] The present embodiment provides a kind of production technology of cemented carbide disc cutting foot knife, comprises the following steps:

[0088] S1. 0.1% ZrO2, 0.5% La by weight percentage 2 o 3 , 6% Co powder, 0.05% Y 2 o 3 , 93.35% WC powder mixed to obtain 1Kg mixture, the WC powder Fisherman's particle size in the mixture is 2um, the Co powder Fisherman's particle size is 1.5um, put 1Kg of the mixture into a ball mill cylinder with a volume of 2L, and add cemented carbide grinding rods 3Kg, the wet grinding medium is industrial alcohol with a water content of 5wt%, the wet grinding time is 30h, the slurry is obtained after wet grinding, the slurry is dried for 5-7h, the dried material powder is mixed with glue and granulated, and then pressed into The disc knife is degummed and sintered, the final sintering temperature is 1450°C, and the heat preservation is 1h, and the disc knife blank is made;

[0089] S2. The processing and molding in this embodiment is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com