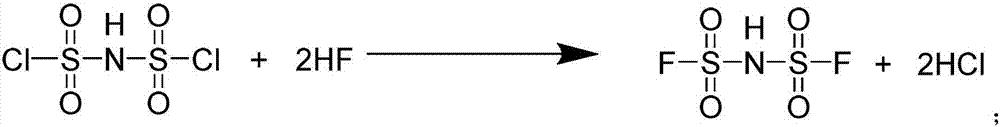

Lithium bis(fluorosulfonyl)imide preparation method

The technology of bisfluorosulfonimide lithium salt and bisfluorosulfonimide is applied in the field of preparation of bisfluorosulfonimide lithium salt, which can solve the problems of poor product crystallinity, influence on yield, complicated process, etc. The effect of low cost, fast response and thorough response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add a total of 1020g of dichlorosulfonimide into a 1000mL reaction bottle, and blow nitrogen to make the whole system under the protective atmosphere of nitrogen and anhydrous conditions. Under normal pressure, start stirring, and heat the system to 75-85°C for 6 hours. , the solid bischlorosulfonimide in the system gradually melted into a liquid state. In the state of stirring, a total of 400 g of anhydrous HF gas was slowly introduced. After a total of about 6 hours of reaction, the system was gradually cooled to room temperature, and the gas in the system was released. The generated white smoke HCl gas was absorbed with lye, and the excess HF was absorbed at the same time. After all the HCl gas was released, the system was heated up. To 50°C, use a water pump with an alkali absorption device in the middle to carry out decompression extraction to extract the residual HF gas in the system. After the extraction was completed, the system was distilled under reduced pres...

Embodiment 2

[0033] Under normal pressure, add a total of 181 g of bisfluorosulfonimide to a 500 mL reaction bottle, add a total of 400 g of anhydrous dichloromethane, and stir to dissolve the bisfluorosulfonimide into a homogeneous system. Place the system in a cold water bath, and when the temperature of the system drops below 20°C, add a total of 180 g of thionyl chloride, stir for 1 hour, weigh a total of 38 g of lithium carbonate solids, and add them to the reaction system in batches. After adding lithium carbonate At the same time, control the system temperature to ensure that the system temperature does not exceed 30 °C. After the addition of lithium carbonate is completed, continue to stir and react for 3 hours, during which the temperature is maintained between 20°C and 30°C. After the reaction is completed, filter the solid filter cake, transfer the solid to the reaction bottle, and use a total of 1200g of anhydrous dichloromethane Washed 3 times, and finally filtered to obtain a...

Embodiment 3

[0036]Under normal pressure, add a total of 181 g of bisfluorosulfonimide to a 500 mL reaction bottle, add a total of 400 g of anhydrous toluene, and stir to dissolve the bisfluorosulfonimide into a homogeneous system. Place the system in a cold water bath, and when the temperature of the system drops below 20°C, add a total of 180 g of thionyl chloride, stir for 1 hour, weigh a total of 25.5 g of anhydrous lithium hydroxide solid, and add it to the reaction system in batches. When adding lithium hydroxide, control the temperature of the system at the same time to ensure that the temperature of the system does not exceed 30°C. After the lithium hydroxide is added, continue to stir and react for 3 hours while maintaining the temperature between 20°C and 30°C. After the reaction, filter the solid filter cake, transfer the solid to the reaction bottle, and wash with a total of 1200g of anhydrous toluene 3 times, and finally filtered to obtain a filter cake, and after drying, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com