Preparation method of amphipathic free radical type polysiloxane-polyurethane prepolymer

A polyurethane prepolymer, polysiloxane technology, applied in the field of polyurethane, can solve the problems of uneven distribution, poor compatibility and stability, and achieve high water resistance, good stability, improved water resistance and solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

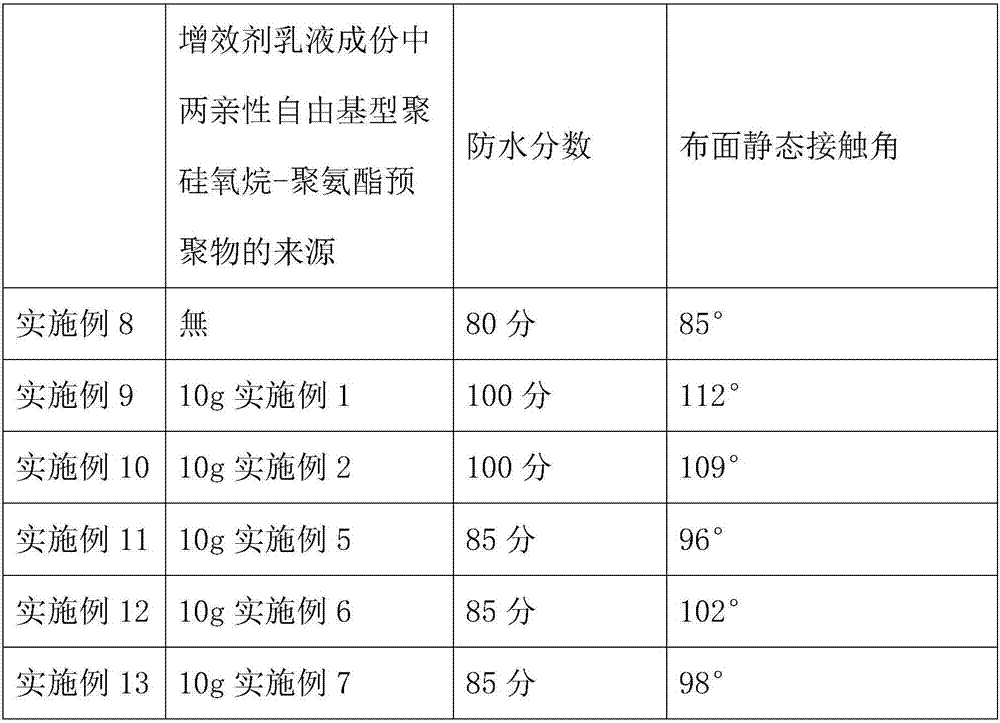

Examples

Embodiment 1

[0039] Example 1: 6g polyethylene glycol (molecular weight 400) was distilled under reduced pressure at a temperature of 120°C and a vacuum degree of 0.09MPa for 1 hour, and then the temperature was lowered to 60°C for use; a thermometer, Add 12g of toluene diisocyanate to the stirring rod and condenser, heat to increase the temperature, and control the temperature between 70-80℃. Add 6g of polyethylene glycol (molecular weight 400) dropwise within 1 hour, keep the temperature for 1 hour after the addition is complete. High to 80-85℃, add 30g of hydroxyethyl silicone oil with molecular weight of 2000 in 1 hour, keep it for 3 hours after the addition is complete; then control the temperature at 70-80℃, and add 0.9g of N-methyl in 10 minutes Diethanolamine, keep the temperature for 0.5 hours after the addition is complete; then add 0.5g of hydroxypropyl acrylate at one time, keep the temperature at 70-80℃, add 1g of glacial acetic acid after 1 hour, keep for 0.5 hours; cool to roo...

Embodiment 2

[0040] Example 2: 6.5g polypropylene glycol (molecular weight 400) was distilled under reduced pressure at a temperature of 120°C and a vacuum of 0.09MPa for 1 hour, and then the temperature was lowered to 60°C for use; a thermometer was installed on a four-necked flask and stirred Stick and condenser, add 12.1g isophorone diisocyanate, heat and increase the temperature, control the temperature between 70-80℃, add 6.5g polypropylene glycol (molecular weight 400) dropwise within 1 hour, keep the temperature for 1 hour after the addition is complete, The temperature was raised to 80-85℃, 32g of hydroxypropyl silicone oil with molecular weight of 3000 was added dropwise within 1 hour, and the temperature was kept for 3 hours after the addition was completed; then the temperature was controlled at 70-80℃, and 0.7g of N-ethyl was added dropwise within 10 minutes Diethanolamine, keep the temperature for 0.5 hours after the addition is complete; then add 0.45g of hydroxyethyl methacryl...

Embodiment 3

[0041] Example 3: 5g polypropylene glycol (molecular weight 400) was distilled under reduced pressure at a temperature of 120°C and a vacuum of 0.09MPa for 1 hour, then the temperature was lowered to 60°C for use; a thermometer and a stirring rod were installed on a four-necked flask And the condenser, add 12.3g isophorone diisocyanate, heat and increase the temperature, control the temperature between 70-80℃, add 5g polypropylene glycol (molecular weight 400) dropwise within 1 hour, keep the temperature for 1 hour after the drop When the temperature is as high as 80-85℃, add 38g of hydroxypropyl silicone oil with a molecular weight of 3000 within 1 hour, keep it for 3 hours after the addition is complete; then control the temperature at 70-80℃, and add 0.93g of dihydroxymethyl within 10 minutes Propionic acid, keep the temperature for 0.5 hours after the addition is complete; then add 0.5g of hydroxypropyl methacrylate at one time, keep the temperature at 70-80℃, add 1g of trie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap