High-solid self-healing waterborne polyurethane acrylate and preparation method thereof

A polyurethane acrylate and acrylate technology, applied in the field of waterborne polyurethane, can solve the problems of poor mechanical properties, narrow applicability, poor water resistance, etc., achieve good dynamic performance, improve low solid content, and automatically repair cracks and scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

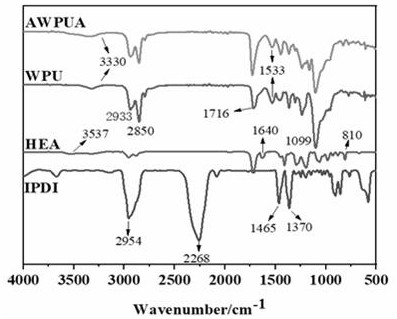

[0022] The preparation method of the high-solid aqueous polyurethane acrylate dispersion that the present invention relates to comprises the following steps:

[0023] Step 1: Add diisocyanate and polyester polyol, or add diisocyanate and polyether polyol to a four-necked flask equipped with standard synthetic reaction equipment (thermometer, condenser, mechanical stirring device), and the added diisocyanate and The ratio of isocyanate group to hydroxyl substance in polyester polyol is 2.5~4:1, the ratio of isocyanate group to hydroxyl substance in added diisocyanate and polyether polyol is 2.5~4:1, and the temperature is raised to 70 ~90°C, react for 1~3h to obtain polyurethane prepolymer.

[0024] Step 2: adding a catalyst, the dosage of the catalyst is 1-2 drops. After adding a viscosity reducing solvent, a hydrophilic chain extender and a chain extender containing a disulfide bond, the first mixed solution is obtained after mixing and reacting. The first mixed solution inc...

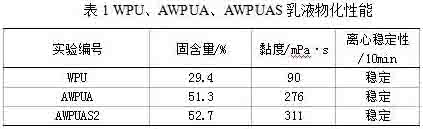

Embodiment 1

[0038] Step 1: Add 5.55 g of isophorone diisocyanate and 20 g of polyester polyol into a three-necked flask equipped with a thermometer, a stirrer, and a glass bottle stopper, mix well, adjust the temperature of the magnetic stirrer to 80°C, and the stirring speed to 300rpm, fully react for 1h.

[0039] Step 2: Add 1-2 drops of dibutyltin dilaurate, add 0.7665g of acetone to the reaction, add 0.7665g of bismethylolpropionic acid, and 1.2775g of 2,2-dithiodiethanol in sequence. Adjust the reactant temperature to 75°C and react for 3h.

[0040] Step 3: Cool down to 50°C, add 1.2775g of hydroxyethyl acrylate, and react for 1h.

[0041] Step 4: Cool down to 30°C, add 0.5777g of triethylamine for neutralization, the neutralization time is 30min, then add 70.3g of water, adjust the stirring speed to 1500rpm, and react for 30min.

[0042] Step 5: Heat up to 50°C, add 18g of methyl methacrylate, 12g of butyl acrylate, 0.3753g of sodium dodecylsulfonate, 0.1877g of fatty alcohol poly...

Embodiment 2

[0047] Step 1: Add 6.66g of isophorone diisocyanate and 20g of polyether polyol into a three-necked flask equipped with a thermometer, a stirrer and a glass bottle stopper, mix well, adjust the temperature of the magnetic stirrer to 70°C, and the stirring speed to 300rpm, full reaction 2h.

[0048] Step 2: Add 1-2 drops of dioctyltin dilaurate, add 1.0664 g of butanone to the reaction, add 1.0664 g of bismethylol butyric acid, and 1.5996 g of TDS in sequence. Adjust the reactant temperature to 80°C and react for 3h.

[0049] Step 3: Cool down to 60°C, add 1.8662g of hydroxyethyl methacrylate, and react for 1 hour.

[0050] Step 4: Cool down to 30°C, add 0.8038g of triethylamine for neutralization, the neutralization time is 40min, then add 77.8g of water, adjust the stirring speed to 1500rpm, and react for 40min.

[0051] Step 5: Heat up to 50°C, add 25.92g of methyl acrylate, 12.96g of butyl acrylate, 0.5433g of sodium lauryl sulfate, 0.2716g of fatty alcohol polyoxyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com