An improved high chromium ferroroller with tungsten modification treatment

A metamorphic treatment and improved technology, which is applied in the field of rolls, can solve the problems of not being able to meet the requirements of the front section of the hot-strip tandem rolling mill, so as to improve the hardness and mechanical properties, improve the metallurgical quality and purity, and improve the hardness and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A. Melting: The chemical composition and mass percentage of the working layer of the roll are C2.30~3.00%, Si0.40~1.20%, Mn0.40~1.20%, Cr13.00~20.00%, W2.00~ 6.50%, Mo0.80~2.00%, V0.05~1.00%, S≤0.03%, P≤0.03%, the rest are Fe and unavoidable impurities;

[0034] Pig iron and scrap steel are used as the base material during batching, and the batching is done according to the above chemical composition. Wherein, all of W is added in the form of a tungsten modifier, and after the molten iron smelting is completed, the tungsten modifier is evenly rushed into the ladle together with the molten iron flow out of the furnace. The molten iron in the working layer is initially smelted in the intermediate frequency induction furnace by the oxidation method, and then refined outside the furnace. The melting and refining temperature of the intermediate frequency induction furnace is 1400 °C;

[0035] B. Modification treatment: when the molten iron comes out of the furnace, add the ...

Embodiment 2~4

[0042] Examples 2-4 have the same manufacturing method as the above-mentioned Example 1, but the different process parameters are shown in Table 1 below.

[0043] Table 1

[0044]

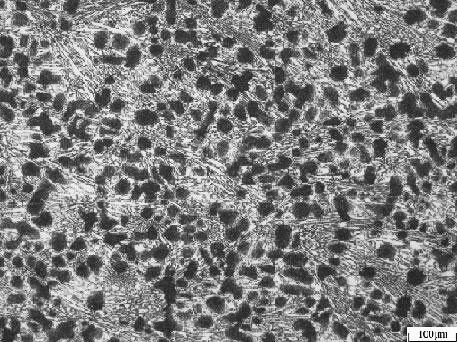

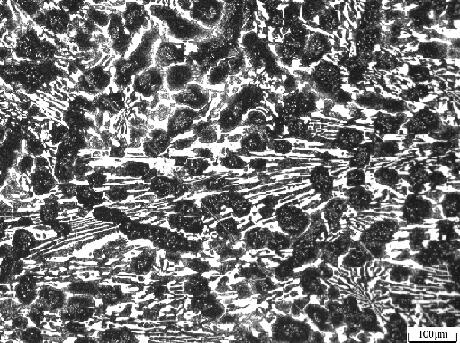

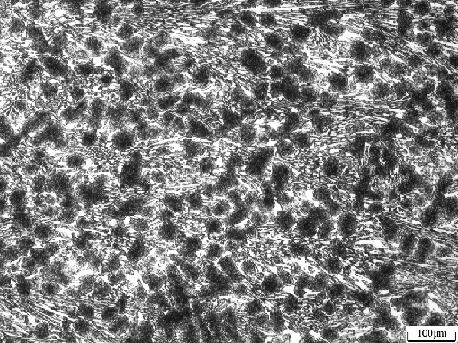

[0045] After testing, the chemical composition, mass percentage and hardness of the roll working layer finally prepared in each embodiment are shown in Table 2, and the metallographic structure is as follows figure 2 , image 3 , Figure 4 shown.

[0046] Table 2

[0047] Example 2 Example 3 Example 4 C (wt%) 2.30 2.40 3.00 Si(wt%) 0.40 1.10 1.20 Mn(wt%) 0.40 0.80 1.20 Cr(wt%) 13.00 17.40 20.00 W (wt%) 2.00 5.20 6.50 Mo (wt%) 0.80 1.10 2.00 V(wt%) 0.05 0.60 1.00 S (wt%) 0.016 0.028 0.012 P (wt%) 0.02 0.024 0.018 Hardness (HSC) 80~83 81~84 82~86

Embodiment 5

[0049] Example 5 is a comparative example, no tungsten modifier is added during manufacture, and tungsten is added in proportion to the ingredients during smelting, and the rest are the same as Example 1. Table 3 shows the results of relative wear resistance, thermal fatigue test (600°C test temperature) and thermal shock test of the final rolled roll.

[0050] table 3

[0051]

[0052]

[0053] It can be seen from Table 3 that the wear resistance of the roll treated with tungsten modification is greatly improved, and the thermal cracking resistance and impact toughness are significantly improved compared with the roll without tungsten modification treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com