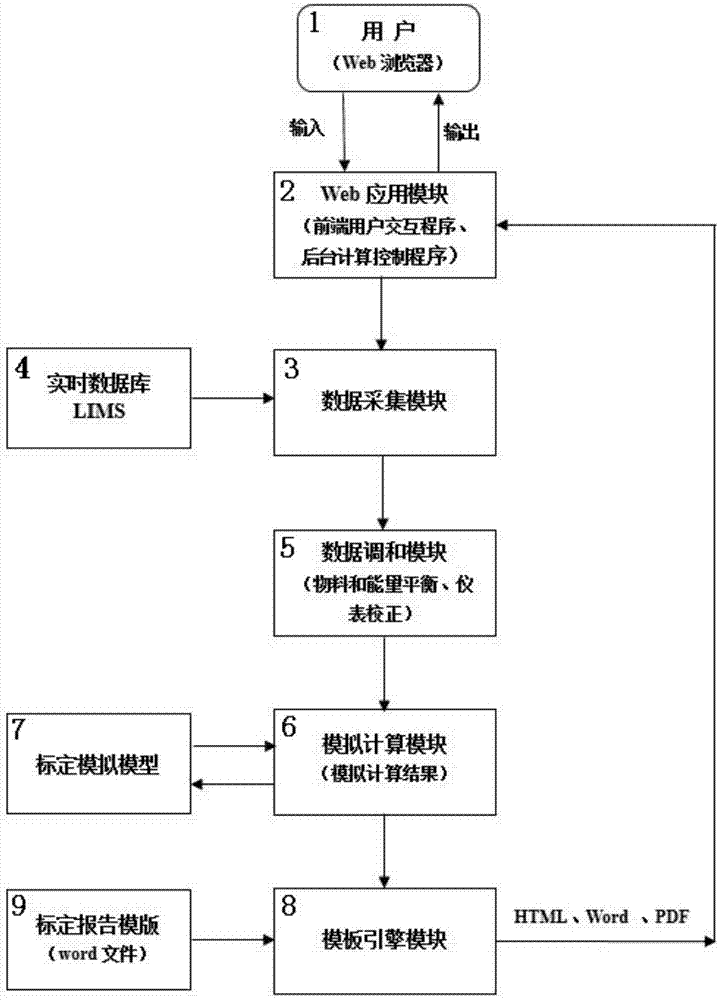

Process simulation software based online calibration system

A technology of process simulation and calibration system, applied in the field of online calibration system based on process simulation software, to achieve the effects of shortening the generation cycle, making up for the lack of measurement data, and reliable and comprehensive calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0106] Taking a delayed coking unit as an example, the description is as follows:

[0107] A delayed coking unit started construction in October 2007, and successfully started up in December 2009, producing qualified products. It uses the vacuum residue produced by the new 10 million tons / year atmospheric and vacuum device as raw material for secondary processing, with an annual processing capacity of 2.3 million tons of vacuum residue. The device covers an area of 210×117=24570m 2 , about 36.855 mu, is located on the west side of the tank area of the Ministry of Aromatics, on the north side of the newly built 200,000 tons / year sulfur recovery unit, and on the south side of the newly built sewage treatment plant. The device is designed by Luoyang Petrochemical Engineering Company (LPEC), and adopts the current domestic advanced process of "flexibly adjustable cycle ratio".

[0108] The delayed coking unit is composed of process production and petroleum coke treatment, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com