Tooth filling and repairing material and preparation method thereof

A technology for repairing materials and teeth, which is applied in dental preparations, dentistry, dental prostheses, etc., and can solve problems such as poor physical and mechanical properties, damaged restoration edge seals, micro-leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

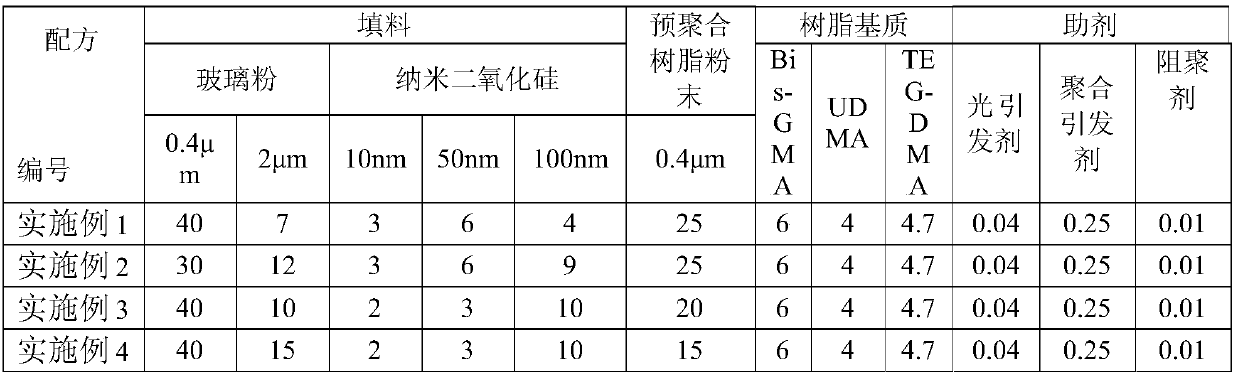

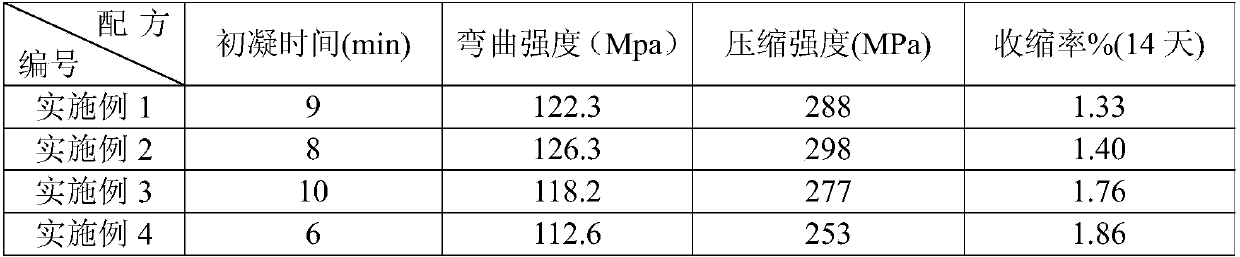

[0093] The raw materials and dosages used in Examples 1-4 are shown in Table 1; wherein, the dosage of each component is calculated according to the mass fraction of the components in the dental filling restoration material.

[0094] The preparation method of embodiment 1-4 dental filling restorative material is the same, and the specific preparation method is as follows:

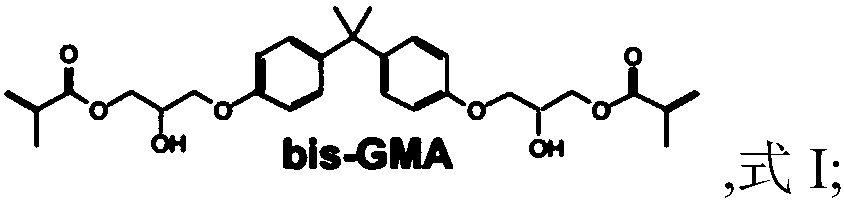

[0095] (1) Preparation of pre-polymerized resin powder: Bis-GMA resin monomer and initiator benzoyl peroxide (BPO) are mixed, and the consumption of benzoyl peroxide is 0.2% of Bis-GMA resin quality, stirs at 50 ℃ 5hr, exhaust for 15min to make the vacuum degree -0.1Mpa. After the stirring is completed, pour it into the tray, the thickness of the material is 10-20mm, and cover the tray with aluminum foil. After the pouring was completed, the tray was put into an oven for polymerization, the polymerization initiation temperature was 65° C., and the polymerization time was 5 hours. After the polymerization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com