Spray drying production process and application of high-activity lactobacillus powder

A technology of lactobacillus and bacteria powder, applied in the direction of lactobacillus, application, bacteria, etc., can solve the problems of limited improvement, unsuitability for industrial application, cumbersome operation steps, etc., to improve functions, improve self-stress resistance, and increase survival rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the spray drying of Lactobacillus reuteri

[0033] (1) Preparation of Lactobacillus film fermentation medium:

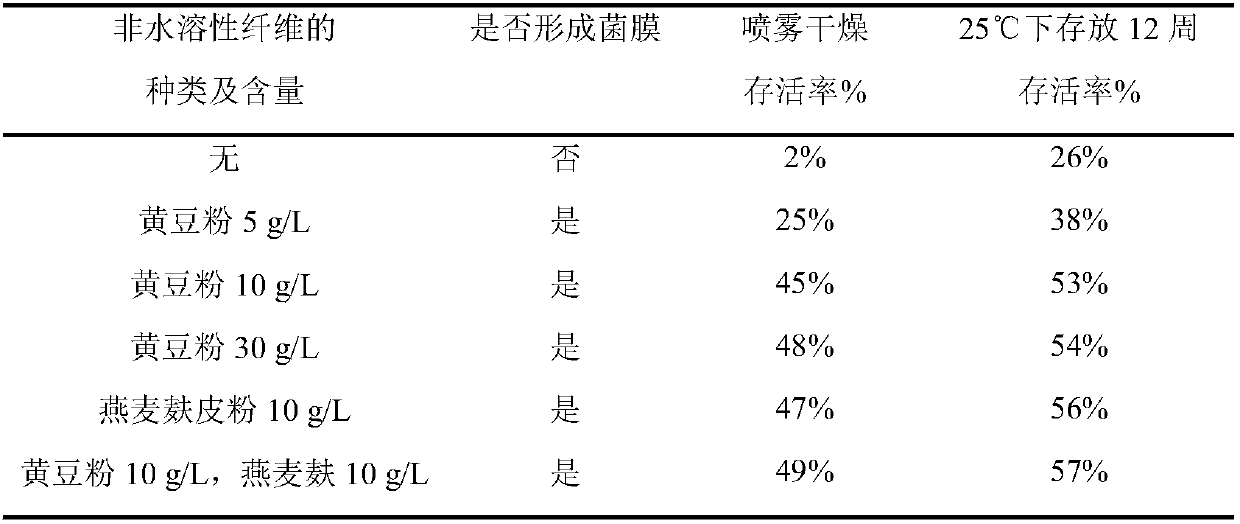

[0034] Preparation of Lactobacillus reuteri membrane fermentation medium: yeast powder 5g / L, anhydrous sodium acetate 5g / L, beef extract 10g / L, anhydrous glucose 20g / L, fish powder peptone 10g / L, magnesium sulfate heptahydrate 0.5 g / L, dipotassium hydrogen phosphate trihydrate 2.6g / L, manganese sulfate monohydrate 0.25g / L, diammonium hydrogen citrate 2g / L, L-cysteine hydrochloride 0.5g / L, Tween- 801g / L, the amount of insoluble fiber added is shown in Table 1.

[0035] (2) Fermentation preparation of Lactobacillus film: activate Lactobacillus reuteri for 3 generations, transfer it to a 10L fermenter according to the inoculation ratio of 3-5%, continuously feed nitrogen, adjust the rotation speed, and keep the pH constant at 37°C (pH=6) and cultivated for 24 hours.

[0036] (3) Collection of Lactobacillus pellicle: Centrifuge the Lactobacillus...

Embodiment 2

[0043] (1) Preparation of Lactobacillus film fermentation medium:

[0044] Preparation of Lactobacillus reuteri membrane fermentation medium: yeast powder 5g / L, anhydrous sodium acetate 5g / L, beef extract 10g / L, anhydrous glucose 20g / L, fish powder peptone 10g / L, magnesium sulfate heptahydrate 0.5 g / L, dipotassium hydrogen phosphate trihydrate 2.6g / L, manganese sulfate monohydrate 0.25g / L, diammonium hydrogen citrate 2g / L, L-cysteine hydrochloride 0.5g / L, Tween- 801g / L, soybean powder 10g / L.

[0045] (2) Fermentation preparation of Lactobacillus film: activate Lactobacillus reuteri for 3 generations, transfer it to a 10L fermenter according to the inoculation ratio of 3-5%, continuously feed nitrogen, adjust the rotation speed, and keep the pH constant at 37°C (pH=6) and cultivated for 24 hours.

[0046] (3) Collection of Lactobacillus pellicle: Centrifuge the Lactobacillus pellicle fermentation liquid at 4°C to collect the sludge. The centrifugation conditions are: the ro...

Embodiment 3

[0050] Embodiment 3: the spray drying of lactobacillus rhamnosus

[0051] (1) Preparation of Lactobacillus film fermentation medium:

[0052] Yeast powder 6g / L, anhydrous sodium acetate 4g / L, beef extract 12g / L, anhydrous glucose 25g / L, peptone 12g / L, magnesium sulfate heptahydrate 0.5g / L, dipotassium hydrogen phosphate trihydrate 2.6g / L L, manganese sulfate monohydrate 0.25g / L, diammonium hydrogen citrate 2g / L, L-cysteine hydrochloride 0.5g / L, Tween-801g / L, soybean flour 10g / L, oat bran Powder 10g / L.

[0053] (2) Fermentation preparation of Lactobacillus pellicle: Activate 3 generations of Lactobacillus, transfer it to a 10L fermenter according to the inoculation ratio of 3-5%, continuously feed nitrogen, adjust the rotating speed, and constant pH at 37°C (pH= 6) Culture for 24 hours.

[0054] (3) Collection of Lactobacillus pellicle: Centrifuge the Lactobacillus pellicle fermentation liquid at 4°C to collect the sludge. The centrifugation conditions are: the rotation sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com