Method for improving stress resistance of streptococcus thermophilus and application thereof in preparation of streptococcus thermophilus powder

A technology of Streptococcus thermophilus and bacterial powder, applied in the food field, can solve the problems of unsuitable industrial application, cumbersome operation steps, limited improvement degree, etc., and achieve the effect of improving self-resistance, high activity, and strong resistance to stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Freeze-drying of Streptococcus thermophilus

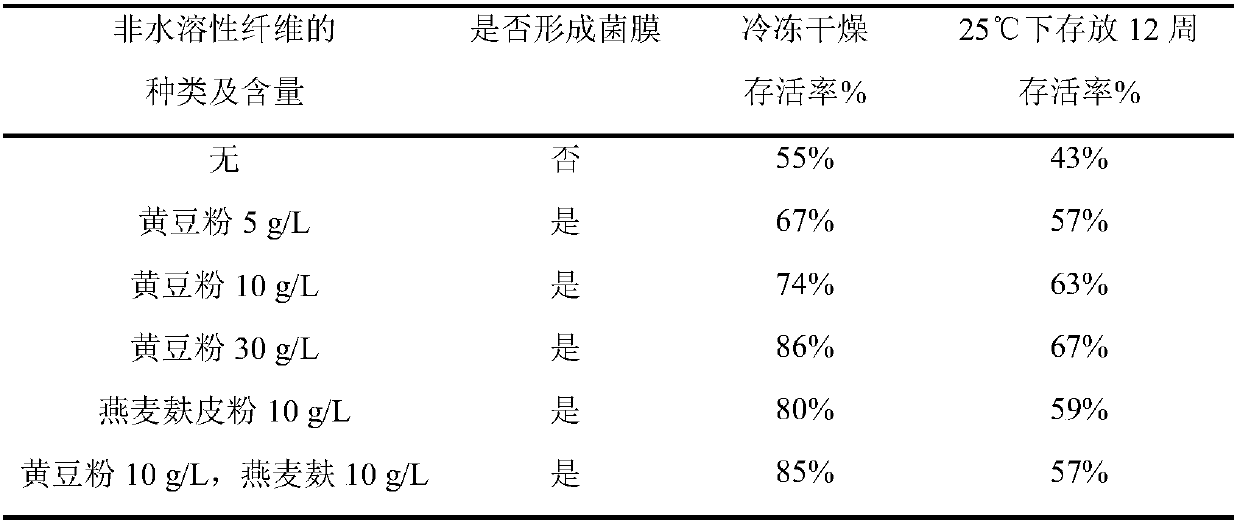

[0032] (1) Preparation of streptococcus thermophilus membrane fermentation medium: yeast powder 5g / L, beef extract 5g / L, lactose 10g / L, tryptone 5g / L, soybean peptone 5g / L, magnesium sulfate 0.2g / L, Sodium glycerophosphate is 20g / L, ascorbic acid is 0.5g / L, and the amount of insoluble fiber added is shown in Table 1.

[0033] (2) Fermentation preparation of Streptococcus thermophilus bacterium film: Activate Streptococcus thermophilus for 3 generations, according to the inoculation ratio of 3-5%, transfer in the 10L fermenter, adjust the rotating speed, 37 degrees of constant pH (pH=6.5 ) for 24 hours.

[0034] (3) Collection of Streptococcus thermophilus pellicle: Centrifuge the fermented liquid of Streptococcus thermophilus to collect the bacterium sludge at 4°C. Streptococcal slime.

[0035] (4) Add drying protective agent: Mix the obtained bacteria slime and drying protective agent according to the weight-t...

Embodiment 2

[0041] Follow the same steps as in Example 1, the difference is that soybean powder and oat bran powder are replaced by kudzu powder and walnut shell powder to carry out bacterial film fermentation, and the results of freeze-drying show that the kudzu root powder and walnut shell powder are used as solid media. The freeze-dried survival rate of the bacterial film was 87%, and the number of viable bacteria in the bacterial powder was 7×10 10cfu / g. The bacterial powder was stored at 25 degrees for 12 weeks, and the survival rate was 60%.

Embodiment 3

[0043] Follow the same steps as in Example 1, except that the freeze-drying protective agent is replaced by: 120g / L skimmed milk powder, 20g / L trehalose, 20g / L sucrose, 0.5g / L cysteine hydrochloride, The pH is 6.5. The freeze-drying survival rate of pellicle-forming Streptococcus thermophilus was 83%, which was significantly higher than the freeze-drying survival rate of bacteria in the non-pellet state. The bacteria powder was stored at 25 degrees for 12 weeks, and the survival rate was 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com