Natural gas transportation pipe high in safety performance

A safety performance, transportation pipeline technology, applied in pipeline protection, pipeline heating/cooling, pipeline protection through thermal insulation, etc., can solve the problems of poor thermal insulation performance, inability to remove impurities, affecting production efficiency, etc., to improve production efficiency, ensure The effect of normal transportation and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

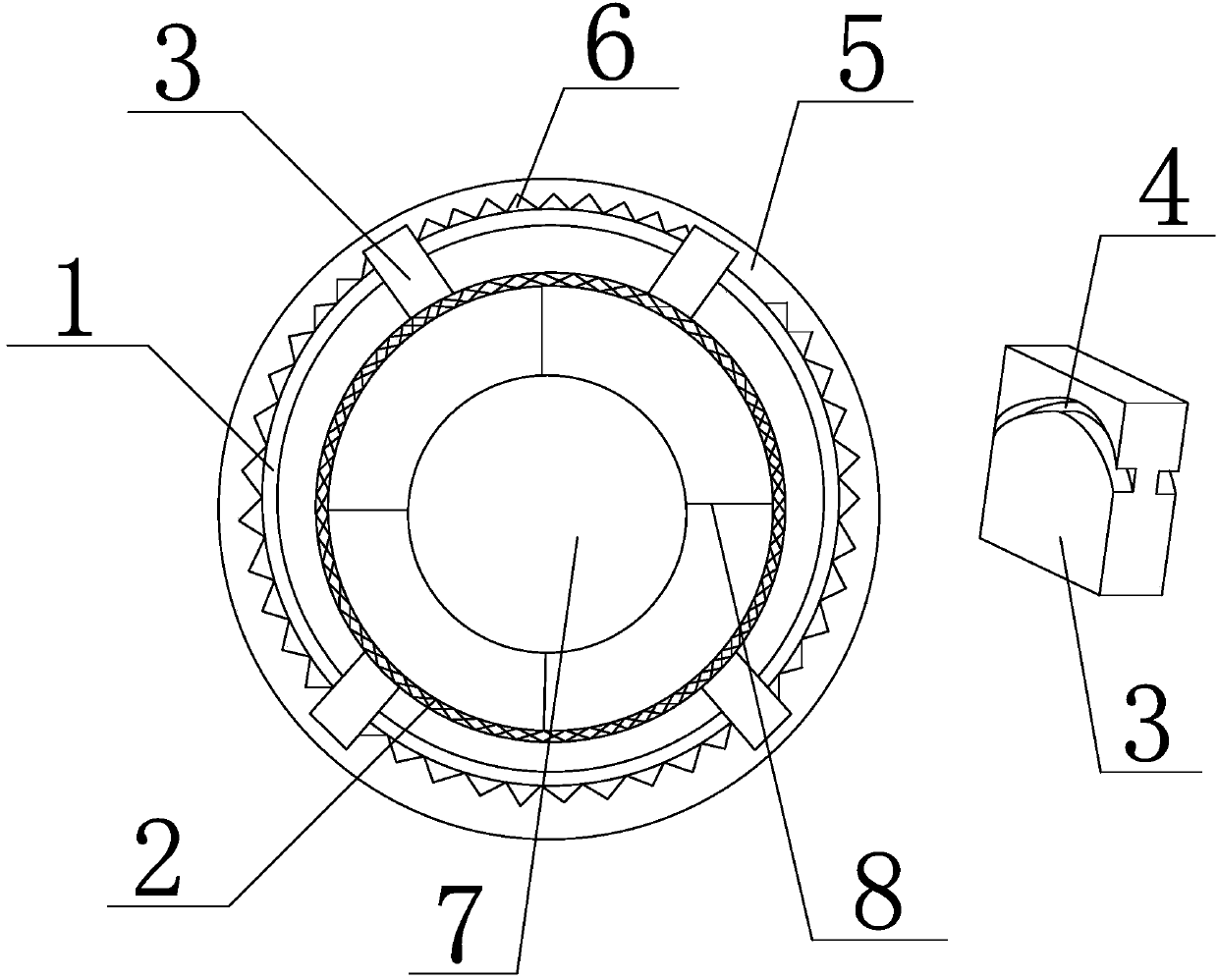

[0021] Such as figure 1 As shown, the natural gas transportation pipeline with high safety performance of the present invention includes a pipeline body 1, and a filter screen cylinder 2 coaxial with the pipeline body 1 is arranged in the pipeline body 1, and the end of the filter screen cylinder 2 is connected to the end of the pipeline body 1. The parts are connected by a plurality of connecting plates 3, and the two sides of the end of the connecting plate 3 connected with the pipe body 1 are provided with arc-shaped grooves 4, and the end wall of the pipe body 1 can be snapped into the groove 4, and the filter screen One end of the cylinder 2 is closed and the other end is open. The outer casing of the pipe body 1 is provided with an insulating layer 5, which is made of an insulating material. The insulating layer 5 is provided with a plurality of annular grooves along the axial direction of the pipe body 1 in sequence. A zigzag rubber ring 6 is arranged, and a cavity is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com