Preparation method of zein based porous hydrophobic oil absorption material

A technology for corn gluten and oil-absorbing material, which is applied in separation methods, chemical instruments and methods, water pollutants, etc., and can solve problems such as difficulty in achieving separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 0.8 g of zein in a round bottom flask, add 40 mL of NaOH solution with a concentration of 0.1 mol / L, and fully disperse the zein under stirring; Raise the temperature to 60°C, stir for 4 h, cool and stand for 50 min, freeze at low temperature and thaw at room temperature 5 times to obtain a columnar hydrogel.

[0037] At room temperature, the columnar hydrogel prepared above was dissolved in 50 mL of iron salt mixed aqueous solution (FeCl 2 ∙4H 2 O and FeCl 3 ∙6H 2 The molar ratio of O is 1:1) After soaking for 60 min, close the system, add 0.1mol / L NaOH solution to precipitate iron salt while stirring, continue stirring for 30 min, filter out the columnar gel, and rinse with distilled water until the eluate is Neutral, to obtain magnetic columnar zein-based hydrogels.

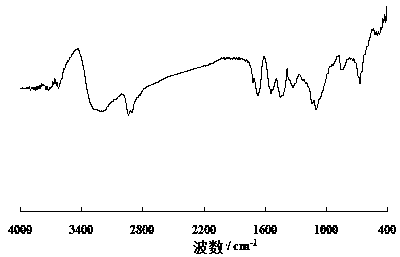

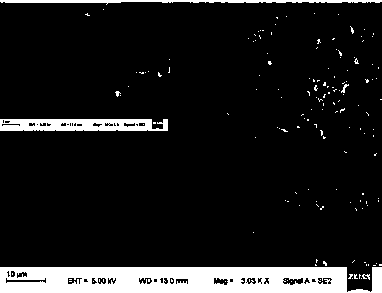

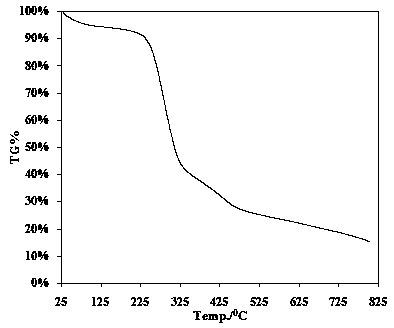

[0038] Soak the magnetic columnar zein-based hydrogel in KH570 ethanol-alcohol solution (concentration: 5%, v / v), shake it at room temperature for 3 hours, take it out, and dry it in vacuum at ...

Embodiment 2

[0041] Take 1 g of zein in a round bottom flask, add 30 mL of NaOH solution with a concentration of 1.0 mol / L, and fully disperse the zein under stirring; Raise the temperature to 70°C, stir for 3 h, cool and stand for 40 min, freeze at low temperature and thaw at room temperature 3 to 5 times to obtain a columnar hydrogel.

[0042] At room temperature, the columnar hydrogel prepared above was dissolved in 50 mL of iron salt mixed aqueous solution (FeCl 2 ∙4H 2 O and FeCl 3 ∙6H 2 The molar ratio of O is 1:2) after soaking for 20 min, close the system, add 1.0 mol / L NaOH solution to precipitate iron salt while stirring, continue stirring for 30 min, filter out the columnar gel, rinse with distilled water until the eluate is Neutral, to obtain magnetic columnar zein-based hydrogels.

[0043] Soak the magnetic columnar zein-based hydrogel in KH570 ethanol-alcohol solution (concentration: 10%, v / v), shake it at room temperature for 2 h, take it out, and dry it in vacuum at 50-...

Embodiment 3

[0046] Take 1.2 g of zein in a round bottom flask, add 45 mL of KOH solution with a concentration of 1.5 mol / L, and fully disperse the zein under stirring; Raise the temperature to 80°C, stir for 2 h, cool and stand for 30 min, freeze at low temperature and thaw at room temperature 3 to 5 times to obtain a columnar hydrogel.

[0047] At room temperature, the columnar hydrogel prepared above was dissolved in 50 mL of iron salt mixed aqueous solution (FeCl 2 ∙4H 2 O and FeCl 3 ∙6H 2 The molar ratio of O is 1:2.5) After soaking for 30 min, close the system, add 1.5 mol / L KOH solution to precipitate iron salt while stirring, continue stirring for 30 min, filter out the columnar gel, and rinse with distilled water until the eluate is Neutral, to obtain magnetic columnar zein-based hydrogels.

[0048] Soak the magnetic columnar zein-based hydrogel in KH570 methanol-alcohol solution (concentration: 15%, v / v), shake it at room temperature for 6 h, take it out, and dry it in vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com