Preparation method of hollow porous microsphere adsorbent

A technology of porous microspheres and adsorbents, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc. Effects of adsorption and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

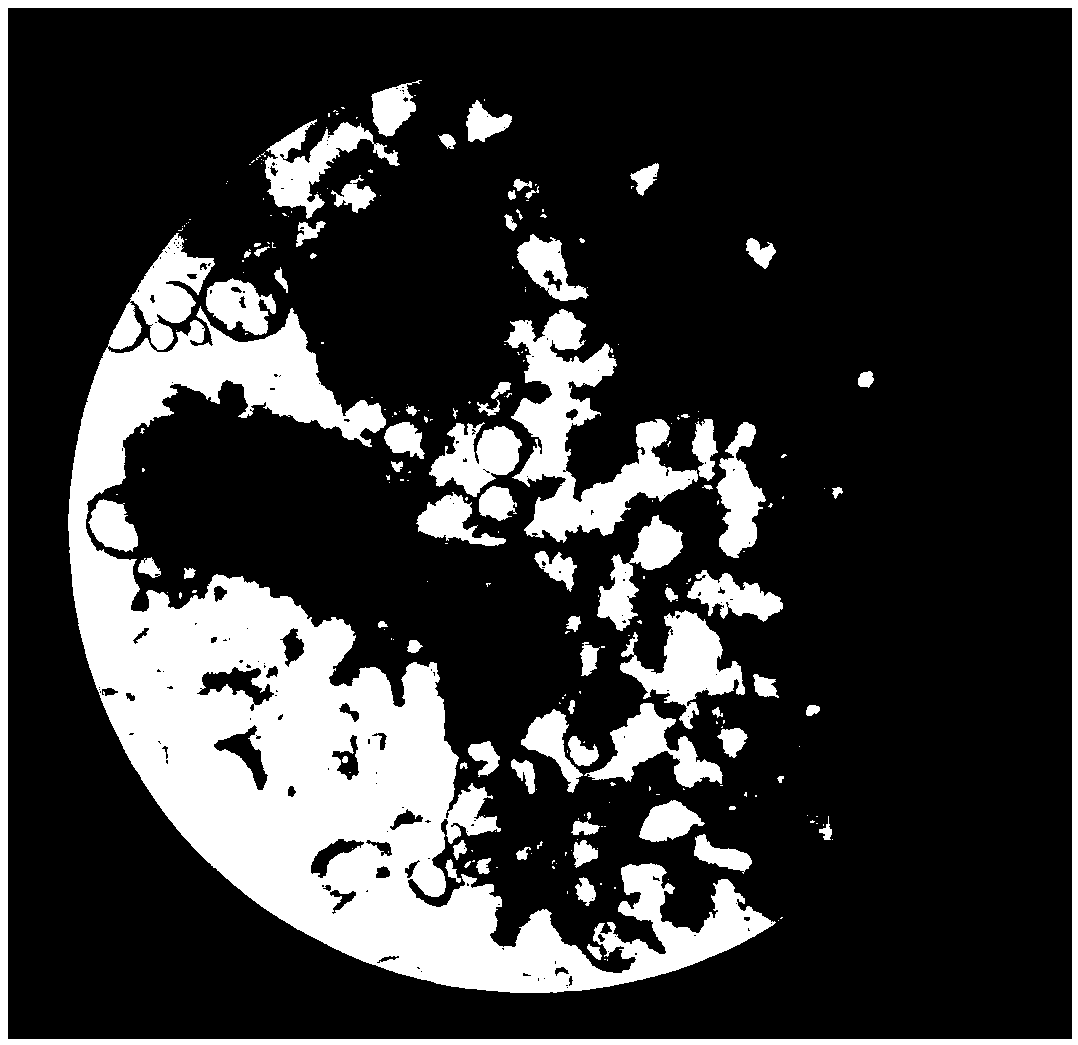

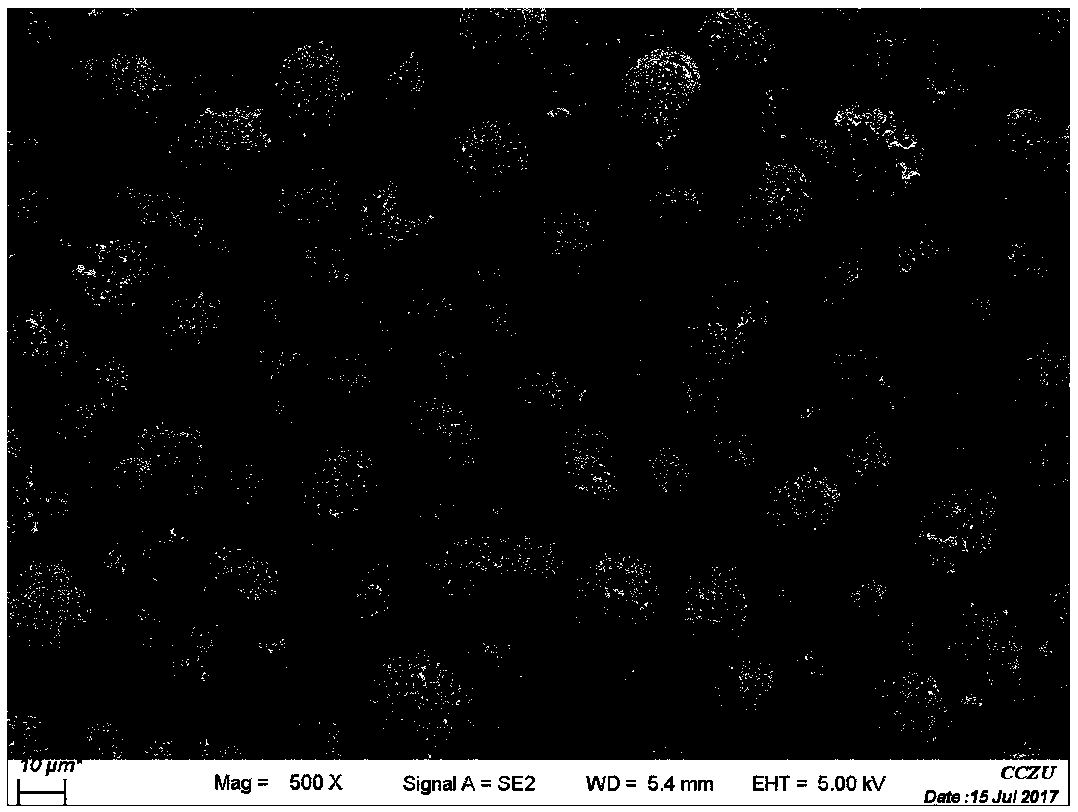

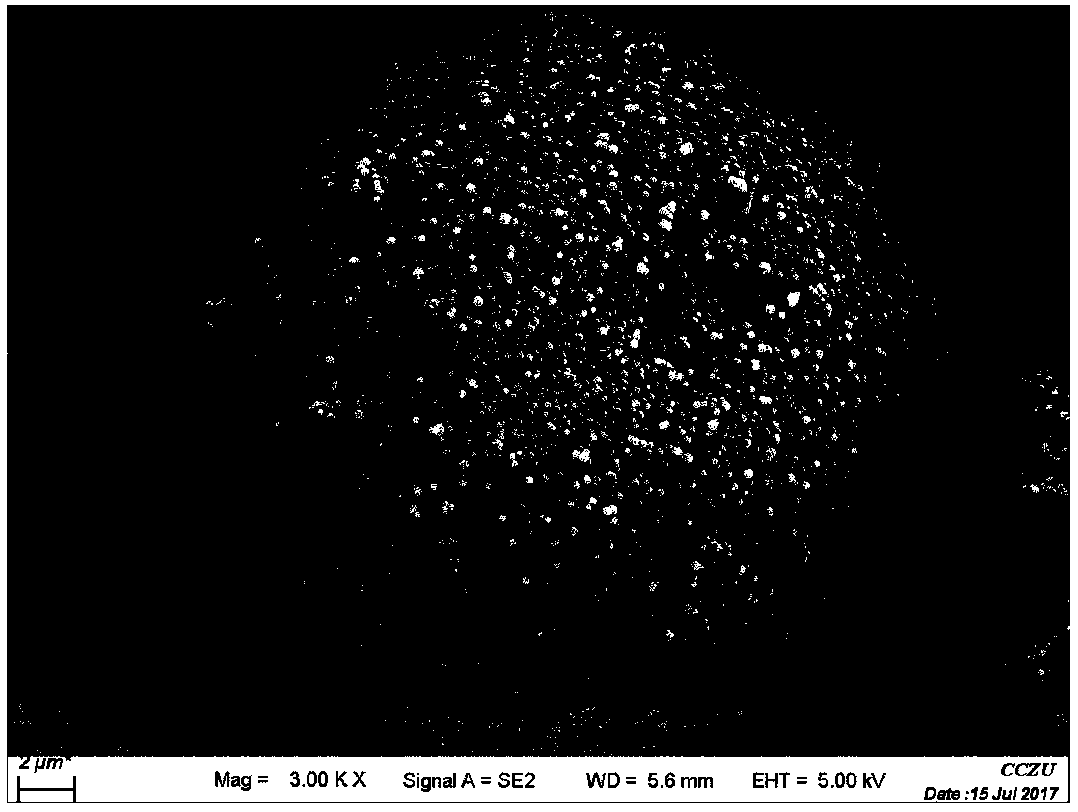

Image

Examples

Embodiment 1

[0020] A method for preparing a hollow porous adsorbent, characterized in that it proceeds in accordance with the following steps:

[0021] The Pickering emulsion polymerization that ZIF-8 nano particle stabilizes prepares the method for hollow porous microsphere adsorbent, carries out according to the following steps:

[0022] (1) Preparation of ZIF-8 nanoparticles

[0023] First, take 0.59g of Zn(NO 3 ) 2 ·6H 2 O was added to 40ml of distilled water, and the stirring was continued until the solution became clear to obtain solution A. According to the taken Zn(NO 3 ) 2 ·6H 2 The amount of O is Zn(NO 3 ) 2 ·6H 2 O: 2-methylimidazole with a mass ratio of 1:70 Take the corresponding 2-methylimidazole and add it to distilled water, and then keep stirring until all 2-methylimidazole is dissolved in distilled water to obtain solution B. The obtained solutions A and B were mixed, stirred at 1000rpm at room temperature for 1h, and finally the obtained solution was centrifug...

Embodiment 2

[0027] A method for preparing a hollow porous adsorbent, characterized in that it proceeds in accordance with the following steps:

[0028] The Pickering emulsion polymerization that ZIF-8 nano particle stabilizes prepares the method for hollow porous microsphere adsorbent, carries out according to the following steps:

[0029] (1) Preparation of ZIF-8 nanoparticles

[0030] First, take 0.65g of Zn(NO 3 ) 2 ·6H 2 O was added to 40ml of distilled water, and the stirring was continued until the solution became clear to obtain solution A. According to the taken Zn(NO 3 ) 2 ·6H 2 The amount of O is Zn(NO 3 ) 2 ·6H 2 The mass ratio of O: 2-methylimidazole is 1:65. Take the corresponding 2-methylimidazole and add it into distilled water, and then keep stirring until all 2-methylimidazole is dissolved in distilled water to obtain solution B. The obtained solutions A and B were mixed, stirred at 2000rpm at room temperature for 2h, and finally the obtained solution was centri...

Embodiment 3

[0034] A method for preparing a hollow porous adsorbent, characterized in that it proceeds in accordance with the following steps:

[0035] The Pickering emulsion polymerization that ZIF-8 nano particle stabilizes prepares the method for hollow porous microsphere adsorbent, carries out according to the following steps:

[0036] (1) Preparation of ZIF-8 nanoparticles

[0037] First, take 0.70g of Zn(NO 3 ) 2 ·6H 2 O was added to 40ml of distilled water, and the stirring was continued until the solution became clear to obtain solution A. According to the taken Zn(NO 3 ) 2 ·6H 2 The amount of O is Zn(NO 3 ) 2 ·6H 2 The mass ratio of O: 2-methylimidazole is 1:75. Take the corresponding 2-methylimidazole and add it into distilled water, and then keep stirring until all 2-methylimidazole is dissolved in distilled water to obtain solution B. The obtained solutions A and B were mixed, stirred at 3000rpm at room temperature for 3h, and finally the obtained solution was centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com