Method for preparing large-area patterned organic light-emitting film by printing

A light-emitting thin film, patterning technology, applied in the directions of copying/marking methods, printing, etc., can solve the problems of poor film quality and inkjet instability, achieve low cost, improve film quality, and overcome the effects of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

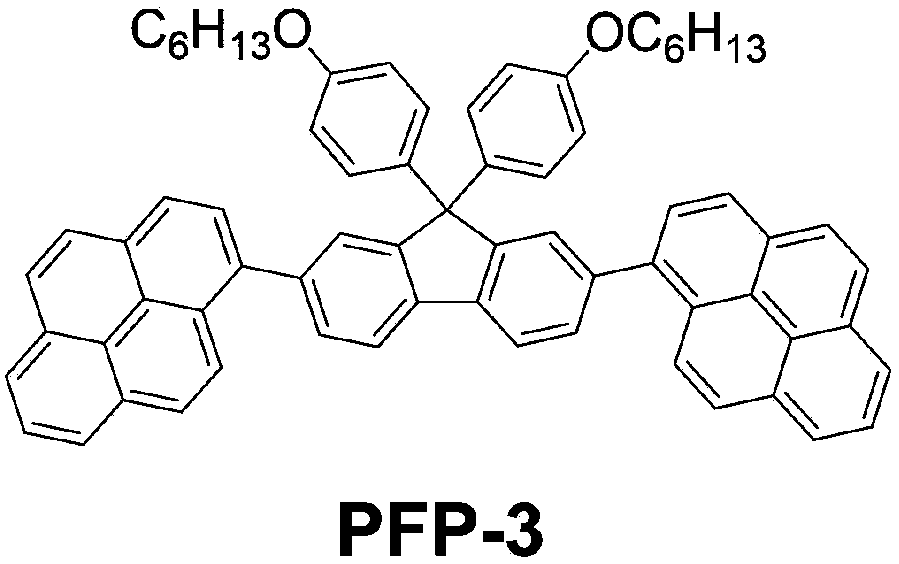

[0031] Select the amphiphilic conjugated molecular material PFP-3 as the solute, the structure is as follows figure 1 shown. Weigh 10 mg of PFP-3 and place it in a container, then weigh 2 ml of the first solvent cyclohexanone and add it to the container to form a mixed solution, then weigh 0.2 ml of the second solvent methylpyrrolidinium and put it into the above In the mixed solution, ultrasonication was performed for 30 minutes at room temperature to obtain a small molecule luminescent material ink suitable for inkjet printing.

Embodiment 2

[0033] First weigh 10 mg of solute PFP-3 and place it in the container, then weigh 2 ml of the first solvent cyclohexanone and add it to the container to form a mixed solution, then weigh 0.2 ml of the second solvent and put it into the above mixed solution , ultrasonicated for 30 minutes at room temperature to obtain a small molecule luminescent material ink suitable for inkjet printing. figure 2 It is to compare the influence of different second solvents on the film-forming properties of small organic molecules in inkjet printing, figure 2 (a) the second solvent employed is methylpyrrolidinium, figure 2 (b) the second solvent employed is phenylcyclohexane, figure 2 (c) The second solvent used is dichlorotoluene. It can be seen from the figure that methylpyrrolidinium is used as the second solvent, which effectively suppresses the coffee ring effect and obtains a relatively uniform printing film.

Embodiment 3

[0035] On the basis of implementation case 2, the optimized organic small molecule ink formula cyclohexanone / methylpyrrolidinium was used. Using glass as the substrate, prepare four different substrate surfaces: ITO surface, ITO surface treated with oxygen plasma, poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid ) PEDOT-PSS surface and oxygen plasma-treated poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) PEDOT-PSS surface, on which organic small molecule materials were printed, respectively. image 3 (a) using an indium tin oxide surface, image 3 (b) the surface of indium tin oxide treated with oxygen plasma, image 3 (c) using poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) PEDOT-PSS surface, image 3 (d) Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) PEDOT-PSS surface treated with oxygen plasma. It can be seen from the figure that the surface tension of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) PEDOT-PSS is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com