Preparation method of graphene material and graphene material

A technology of graphene and graphite, which is applied in the field of new material preparation, can solve the problems that affect the large-scale development and application of graphene, increase the internal defects of graphene, and easily destroy the crystal structure, so as to improve the magnification, cycle performance, and high-quality structure , the effect of less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention provides a kind of preparation method of graphene material, comprises the following steps:

[0046] S1: placing graphene oxide containing metal impurities and / or non-metal impurities in a carrier, and putting the carrier into a high-temperature vacuum furnace. In this step, the carrier uses a graphite bowl, because the melting point of graphite is as high as 3652°C, which is much higher than the melting and boiling points of common metal impurities and non-metal impurities, and during the treatment, graphene will not be introduced due to the carrier material. other elemental impurities. But not limited thereto, the carrier material can also be selected from other carrier materials with higher melting and boiling points, such as tungsten foil, tantalum carbide carrier or hafnium carbide carrier. In this step, graphene oxide is placed in the carrier in a tiled manner. The advantage of using tiled tiles is that tiled graphene oxide has a larger heating area,...

Embodiment 2

[0052] The invention provides a kind of preparation method of graphene material, comprises the following steps:

[0053] S1: placing graphene oxide containing metal impurities and / or non-metal impurities in a carrier, and putting the carrier into a high-temperature vacuum furnace. In this step, the carrier is selected from a graphite bowl, and the graphene oxide is placed in the graphite bowl in a tiled manner. In this step, the high-temperature vacuum furnace is a purification furnace. The preparation method of graphene oxide is the same as that in Example 1.

[0054] S2: evacuate the high temperature vacuum furnace to a negative pressure of 93Pa. Specifically, open the vacuum system of the purification furnace and evacuate to a negative pressure of 93Pa.

[0055] S3: Set the temperature of the high-temperature vacuum furnace to 2200° C., and heat for 180 minutes.

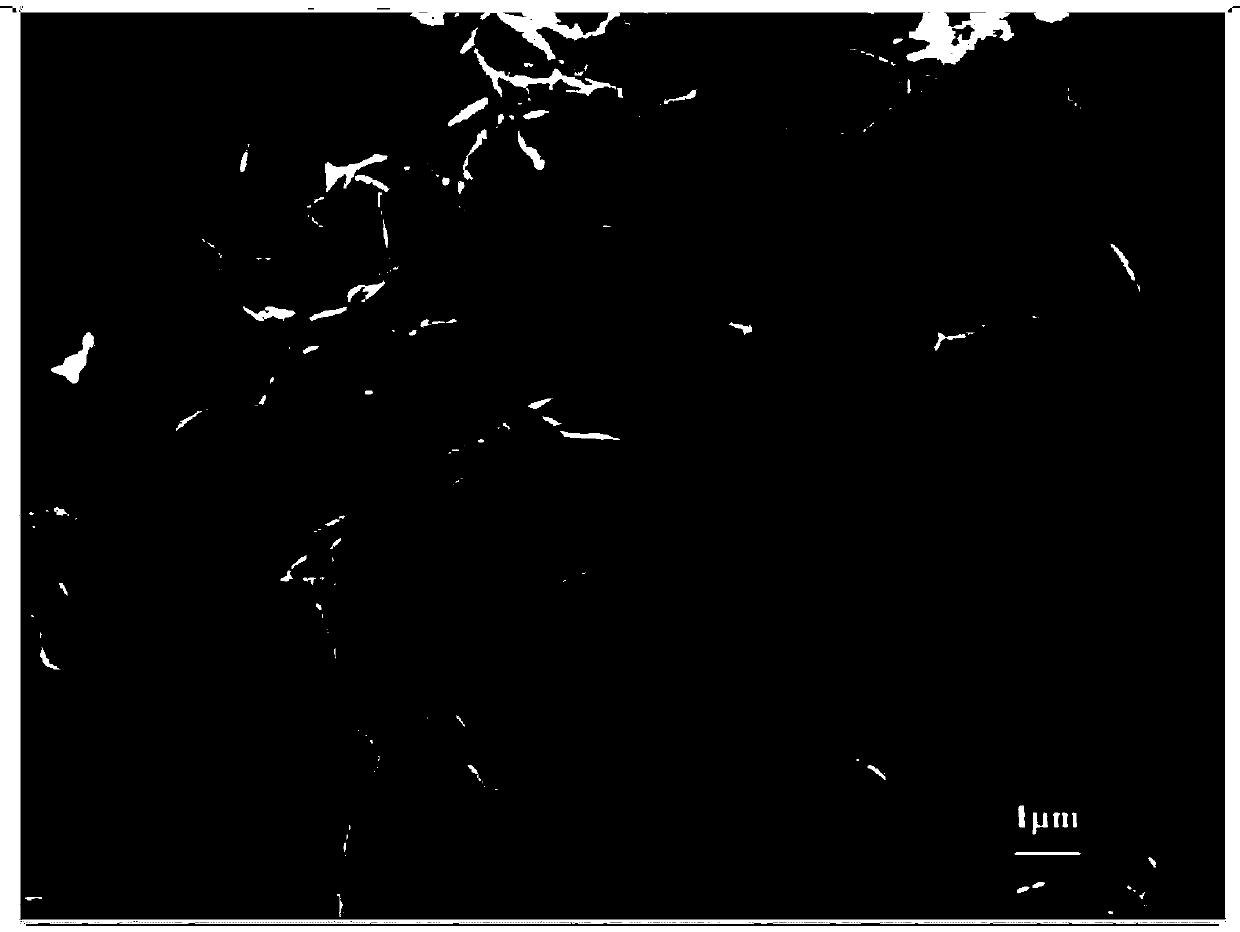

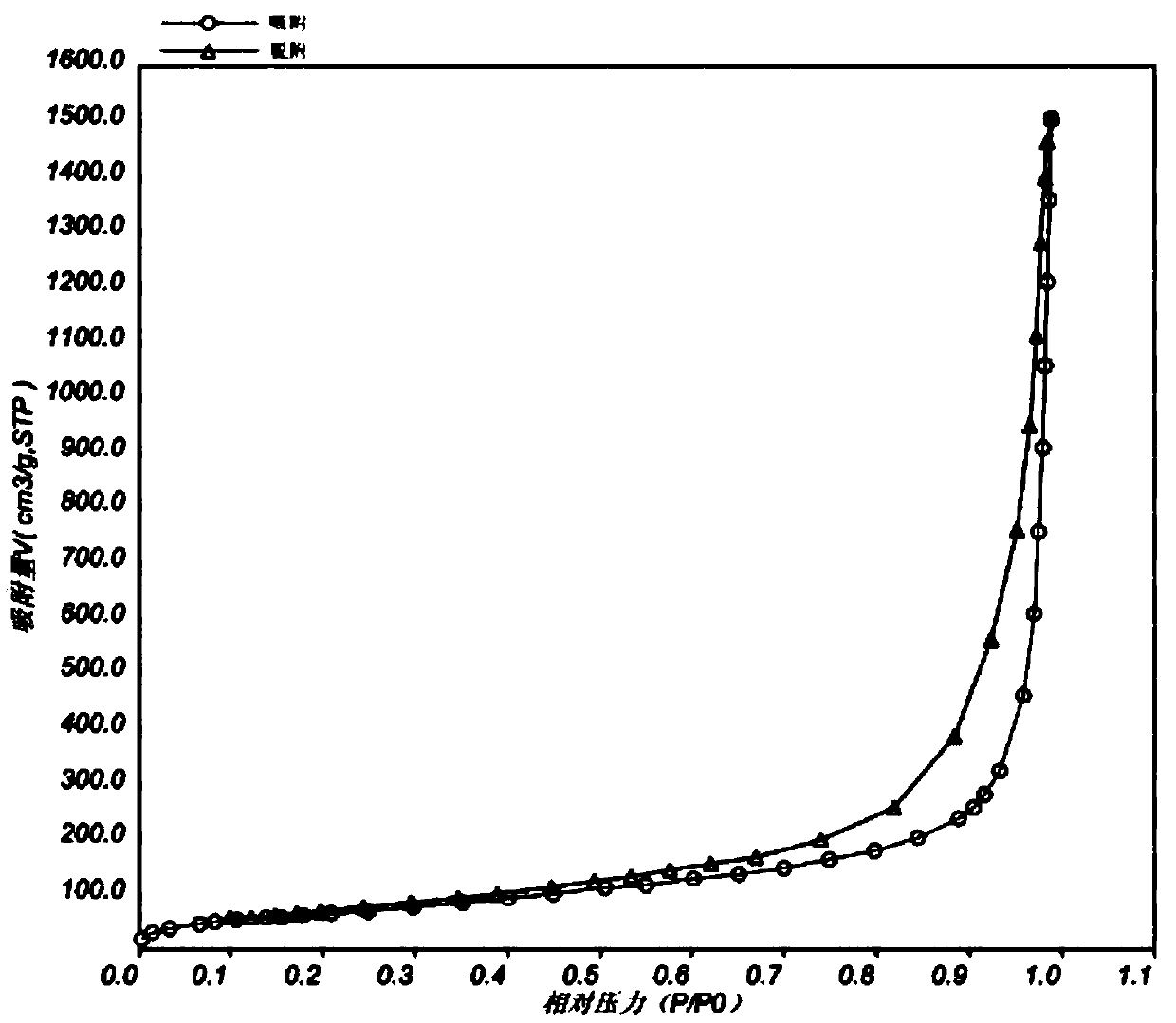

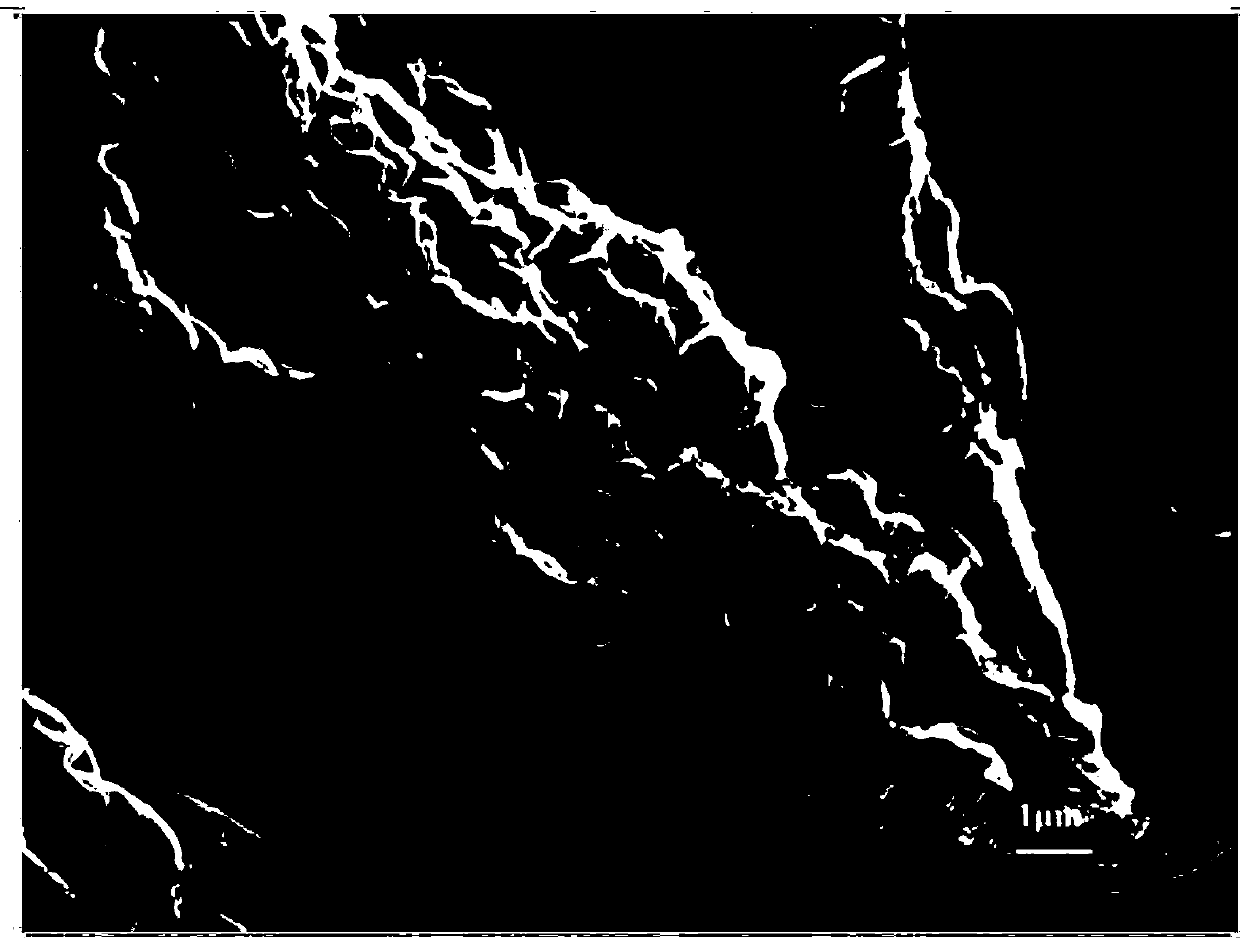

[0056] After the above three steps are completed, the graphene material is obtained. After reaching room te...

Embodiment 3

[0058] The invention provides a kind of preparation method of graphene material, comprises the following steps:

[0059] S1: placing graphene oxide containing metal impurities and / or non-metal impurities in a carrier, and putting the carrier into a high-temperature vacuum furnace. In this step, the carrier is selected from a graphite bowl, and the graphene oxide is placed in the graphite bowl in a tiled manner. In this step, the high-temperature vacuum furnace is a purification furnace. The preparation method of graphene oxide is the same as that in Example 1.

[0060] S2: evacuate the high temperature vacuum furnace to a negative pressure of 93Pa. Specifically, open the vacuum system of the purification furnace and evacuate to a negative pressure of 93Pa.

[0061] S3: Set the temperature of the high-temperature vacuum furnace to 2200° C., and heat for 300 minutes.

[0062] After the above three steps are completed, the graphene material is obtained. After cooling to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com